"So I'm NOT Going Crazy!!!" - Stealth Water Methanol Injection - [SH2OMI] - 2nd Supplemental Update 28.05.2018

Hello Folks,

Well, as you've probably seen in my last post: https://steemit.com/cars/@eggmeister/am-i-going-crazy-stealth-water-methanol-injection-sh2omi-supplemental-update-24-05-2018 I was pretty much stumped as to why the relay wasn't working with power added when insitu in the car but worked fine on the benchtop.

Well this morning and with a fresh mind, I decided to see what the voltage from the wiring in the scuttle (from the glovebox control unit) was giving me. The video below will expand upon this process.

What could I try next to alleviate the current demand (if that really is the issue)?

- A low-current micro-relay?

- Disconnect the bulb in the boost gauge to free-up current?

As I'm taking my activation/control unit 12v feed from a switched small lighting circuit (with thin wires as seen in previous posts regarding the glovebox installation), are the thin wires holding back the current flow?

So I'm not crazy but I'm still confused folks!

Bye for now,

EggMeister.

All previous posts on this project can be found here:

https://steemit.com/cars/@eggmeister/nbx0ndi8

https://steemit.com/cars/@eggmeister/q3wyu12m

https://steemit.com/cars/@eggmeister/yedjwzu8

https://steemit.com/cars/@eggmeister/79lsrrbd

https://steemit.com/cars/@eggmeister/8swbskan

https://steemit.com/cars/@eggmeister/btxnk2px

https://steemit.com/cars/@eggmeister/a-question-guys-electrical-expertise-required-diy-sh2omi

https://steemit.com/cars/@eggmeister/increasing-power-diy-water-methanol-kit-sketches-and-musings

https://steemit.com/cars/@eggmeister/more-power-water-methanol-injection-product-placement

https://steemit.com/cars/@eggmeister/sh2omi-should-i-diy-stealth-water-methanol-injection-system

Place an MTP3055E Tmos power FET under the ground side of the relay (Source to coil, Drain to ground, Gate to the existing activation signal)Tie the top of the relay to any concienent hot lead. Done. The FET will unload your activation signal, and switch the load (relay) across whatever power you connected that relay to.

Look at it like a relay with source to drain as the NO contacta, and Gate to Drain as the coil.

Hello @smithlabs, I've read your comment 3 times now and I'm still confused LOL.

Whether this helps or not with what you're trying to tell me, I'll bring you up to speed and my latest testing (I've yet to do a steemit post about it):

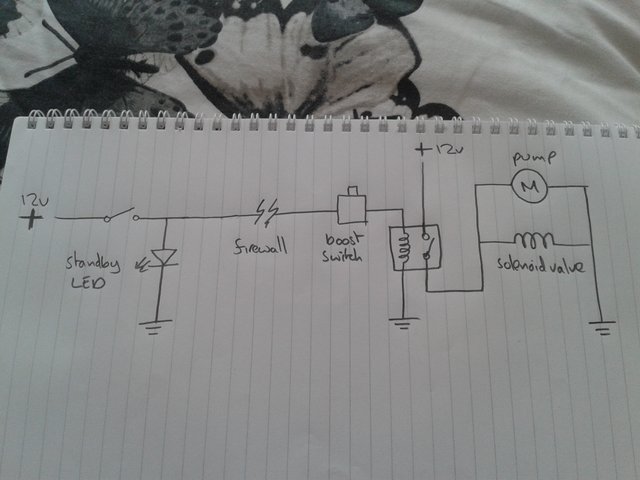

Yesterday, I ran the control unit on 'the bench' (top of fridge in garage ;) and in turn I bypassed the 'standby' LED (which included the boost gauge LED) and then bypassed the 'Active' LED. I'll include an original schematic on the control unit below.

The switch has an integrated LED so this and the gauge LED (both classed as 'standby' LEDs) were bypassed first and the relay wouldn't click. I reconnected these and then bypassed the 'active' LED in the circuit and the relay would click and draw around 200mA (if I remember correctly). So could it be a case of just installing a resistor before or after the 'active' LED to encourage the relay to click or is it a case of the MTP3055E Tmos power FET? There's not a lot of room behind the control unit panel when installed in the glovebox so ideally I need it as simple as possible.

If all else fails, I might just go with ditching the 'active' LED altogether and just have the switch, 'standby' LED and boost gauge. If I do go this route, I might re-fabricate the control panel as the existing one is quite thin aluminium plate and it bends quite easily, especially where there's not much material (above and below the gauge dial). I have some thicker 'diamond plate' in the garage, that might look nice ;)

Anyhoo, I greatly appreciate you help :)

Rob.

http://www.alldatasheet.com/datasheet-pdf/pdf/23381/STMICROELECTRONICS/MTP3055E.html

Here is a TMos Fet (T channel Metal Oxide Semiconductor Field Effect Transistor) Data sheet for the MTP3055E transistor.

It acts a lot like a relay, and will directly switch 12 amps of load at up to 60 volts, with a single microprocessor pin driving the gate. Your active led needs to be closer to the pump, to show actual operation of the pump.

This device has 3 leads:

*Gate (controls the switch like a relay coil))

*Source (Positive lead on device - like relay contact)

*Drain (Negative lead on device - like relay contact)

If you place the Source under the ground side of the pump and solenoid; and connect the Drain to ground, and lastly connect the Gate to your switch. When you power the gate, the MosFet will turn on, and an active LED across the pump will light when it runs.

The relay can be scrapped (this is MUCH more reliable); but get the boost running before you worry about indicator lights. You will need to heat sink the MosFet, at 5 amp load it will disapate under 3 watts as heat.

(P = I squared X R) where R = Rds on (resistance drain to source when turned on) of 0.1 ohms.

Hi @smithlabs, many thanks for your time on this issue.

I think I'm getting to grips with it now. As the control unit is in the glovebox and the pump/solenoid is under the bonnet, I'm not sure as yet how to get the active LED close to the pump. Does the Gate require very little current to switch? I see from the data sheet that it can handle 20v on the gate so 12v car battery shouldn't be an issue. If that's a correct statement on my part.

I think I need a fresh mind and fresh piece of paper tomorrow and have a re-think of the circuit to switch to the transistor option.

Who'd have thought a relatively simple system could render me powerless LOL

Thanks again,

Rob.

Almost zero current as it is a voltage controlled device. You could run a 30 awg wire, and it would work perfectly, but run normal wire size.

Speaking of which, I would run a small jacketed wire pair to the pump for LED drive.

BTW, LEDs will burn up, unless you put a resistor inline to limit the current flow inside the LED. You can use a 1000 ohm resistor, inline, for most LEDs.

Hi @smithlabs, again, many thanks for all your advice.

Under the heatshrink the 'active' LED appears to have a resistor fitted, I measured the resistance at 550 ohms.

Going back to what you said in a previous post about concentrating on getting the boost sorted (or words to that effect ?:) I've decided to ditch the 'active' LED circuit, I tried rejigging it in parallel to the relay and also a 12v return line to it from the pump/solenoid feed instead of relay return but all to no avail. I could get the relay to click with both re-jigged circuits but the 'active' LED sometimes worked, most times not. The project has lots of issues from exploding pipes, leaks and many human errors and has run on too long now as I started it back in January.

I need to feel the extra power under my right foot now ;)

Much appreciated though for all your help, I will hopefully one day modify to include a successful 'active' indication.

Regards,

Robert.

latest, simplest, fully working design

You need to add a resistor in line with the LED, or it will only light once.

Here is how I would do it:

The LED is the active indicator. A bi-color LED (green & red) would be a nice add, after it is running.

:)Ah, that's brilliant.... thank you :)

I've saved the image to my desktop.

Much appreciated :)