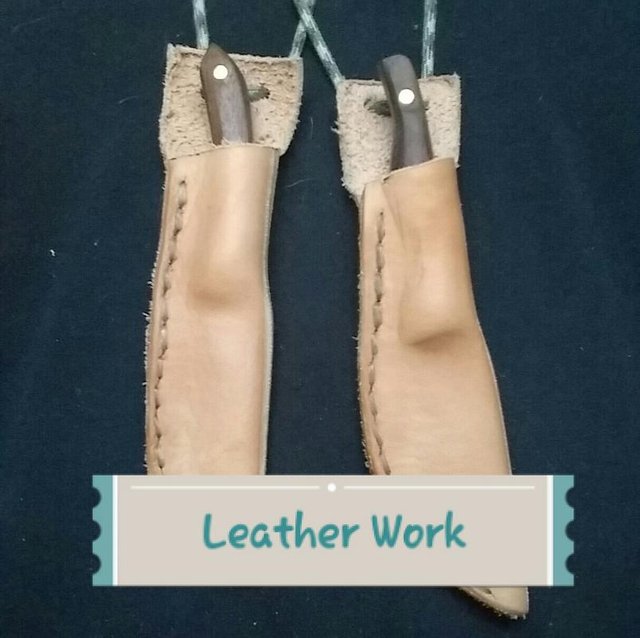

How I make custom @freedompoint knives step 7: Leather sheath

This is it. The last step before the sale. It is time to make the custom leather sheath for each knife. I make each sheath to fit each knife custom. I use what tools I have available and a bit of imagination. I hope you enjoy this part of the build!

Tools and Material

My tools are very simple. I use 8-9 oz. cowhide leather. I order a double shoulder from Springfield Leather. I use a diamond point punch and a round piece of fire wood. I sew the leather using waxed imitation sinew with leather needles. I use a piece of 2x wood as an anvil. Anything that I might have handy.

Cutting out the leather

I roll out the leather and trace the knife onto the leather. I roll the knife over and trace it again. This gives me an idea of how much it will take to make a pouch style sheath. It is solid at the spine of the knife and stitched down the cutting edge.

I typically try to use the knife I made to cut the leather that makes its sheath. I find it sort of poetic.

I cut the leather out and wrap it around the knife to check for the fit. Usually at this point you know if you have enough, or if you cut it too small.

There is another small piece that needs to be cut out. I have known it to be call a 'weld'. This small piece will get stitched into the seam. It helps to prevent the blade from cutting the stitches in the sheath.

Punching holes

I mark inside the edge of the sheath about 1/4" and draw a line. I do this up both sides. Once I determine where to start I use the punch and the stove chucker to punch holes up the edge to the predetermined stopping point. I repeat this on both sides and the weld. You have to make sure you have the same number of holes in every place.

Stitching

Once I have all of the holes punched I use a needle to spread out the holes a bit more. I put all of the pieces together and start stitching from the point. I use a saddle stitch. This is a needle at each end of a long piece of sinew and then put both needles through the same hole, but in opposite directions. You do this all the way to the last hole, then four holes backwards, tie and burn

Shaping the leather

Once it is all stitched up it is time to clean up the edges and shape the leather. I use my 1x30 belt sander to quickly clean up any rough spots and make a consistent edge.

I wrap the knife in some sort of plastic cling wrap and put it in the sheath. I soak the sheath under running water to get in all wet. I use my fingers to press down and shape the leather around the knife. This will give it a tight fit and even pop when you put the knife in.

I use a spoon to burnish the edges. This gives it a smooth and worn look.

Finishing touch

To finish it off I add my makers mark and lanyard. I use another knife to carve in my symbol on the backside of the sheath. I use a leather hole punch to make two holes. For these two I used 550 cord with adjustable knots.

If you enjoyed this post, please check out the rest of the build. Stay tuned for the next step, The Sale.

This has been an awesome series. I have learned much. Thanks for posting!

Thank you! I don't know what I might make next!

Very cool! I love it.

Thank you!

Love the look of the leather sheath. You just keep on impressing. Great work.

Thanks man! I really enjoy it!

Nice shot there @freedompoint

Thank you!

This has been a great series your a very talented individual. You have inspired me to try and get a forge built and give it a go!

Yes! Thank you! I think we all need to try heating and beating!

This is a complex and interesting craft. But the result is worth it. Nice knife! Good work! Godspeed!

Thank you. I love it. I prefer to throw pottery. I love doing anything that shapes earth.

This is very cool stuff. I have some leather hide around here and some knives without sheaths. I think I may "carve" some time out of next weekend to try this out.

So when might we find you on the TV Show "Forged in Fire""

By the way I found this post on @jerrybanfield's #resteem-request channel on discord

What?! Really! I hope I get it! Thank you for checking me out! Did you see the rest of the series. I made a couple of blades and documented itYou should definately try doing it if you havent!🙃

I will have to go back and look at the rest of your post on this. My wife LOVEs the forged in Fire series and never misses an episode. I have messed around with a small forge a few years ago and will likely attempt it again. I love tinkering with homestead projects. I have built my own wind turbine, actually three of them, different designs. I have a solar panel kit about half finished. so I need to complete it. I built a solar water heater for our swimming pool, that rocked! But I never got my forge to work right so I gave up before I got burned or hurt from some kind of explosion.

But I was not aware of your post until I started looking on Jerry's discord channel. Part of his agreement to resteem is to rate at least 5 other post and interact with one of them. What O am finding is I am rating at least ten and interacting with most of them. If it is worth the rate it is worth commenting on.

So I will go back and review the whole knife series, am sure my wife @addiemae will also.

I am sure glad to meet you! I do like the show, but have only seen it once.

It sounds like you have your hands in a whole bunch of projects! We hope to do turbines and solar this coming year...maybe.

The Jerry discord has been alot of fun. I find I am doing the same thing. I have mostly read thosr discord posts today. I am having a problem voting though. Maybe because I am on a mobile phone, but it won't let me vote unless someone has already voted.