Fused Deposition Modeling - The most popular 3D printing technique

Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF) is the most popular printing process due to its cheap cost and easy handling which make it office-friendly. It is not the only printing process and has disadvantages as well. Other processes can yield better results or handle different materials. As always there is a tradeoff to make.

Operation

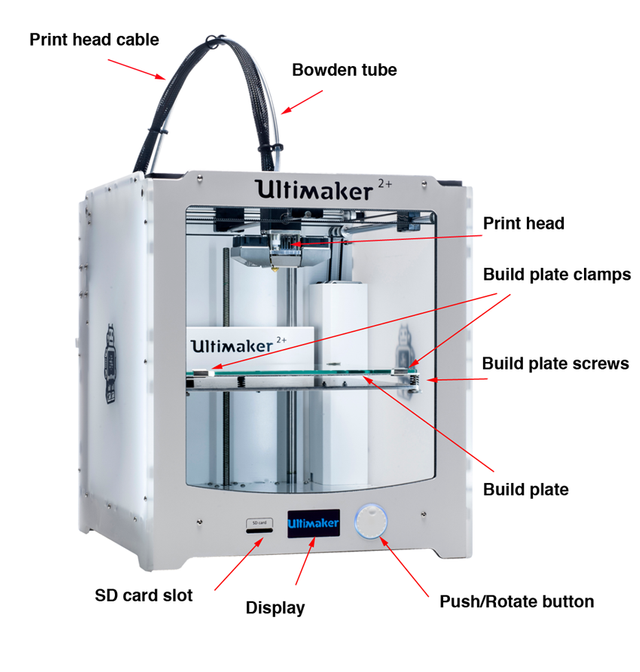

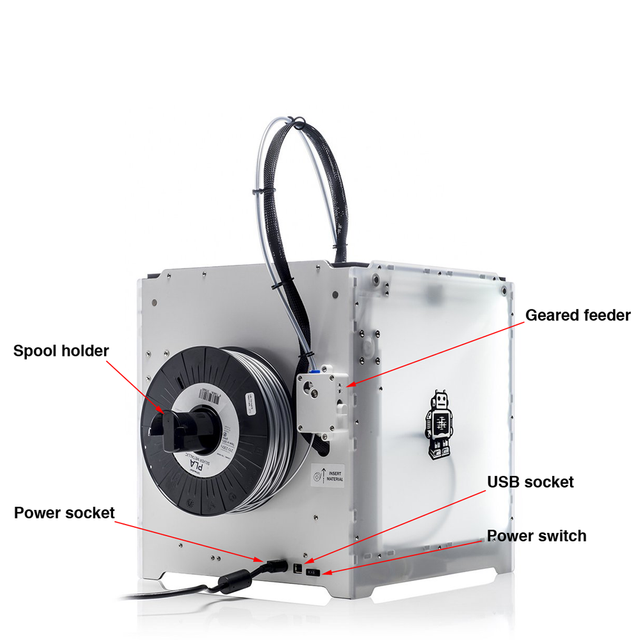

A FDM printer consists of three main elements. A build plate on which the part is printed. A filament spool that contains the printing material and an printing head. These images are from a printer I use myself. The printing head moves left-right and front-back. The plate moves down a tiny bit for every layer. In a previous article I gave a detailed example with lots of images how these layers are built up. Most printers move the build plate up down but there are also printers available that keep the build plate static and let the printhead move in X, Y and Z directions.

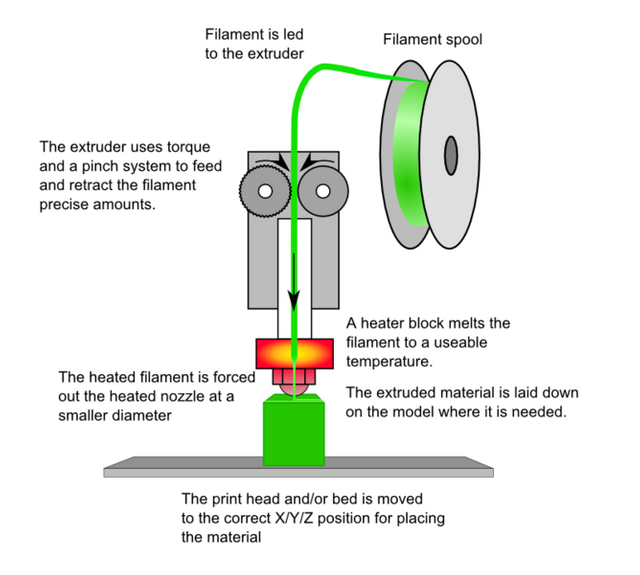

The filament is driven and melted by the extruder in the printing head. The extruder is a centeral part of the printer. It is where the filament gets drawn in, melted, and pushed out. You can think of it as a molten plastic gun, a bit like a glue gun. It is small, but essential and mostly on of the most expensive parts of the printer because it contains quite a bit of technology. It’s also often very customizable. The extruder consists of two parts, the hot end and the cold end. The cold end has a motor that draws the filament in and pushes it through. The hot end is where the filament gets melted and pushed out to be printed.

Price range

There is a whole range of printers available on the market ranging. On the very low end there is for example the https://all3dp.com/history-of-the-reprap-project, a very cheap opensource diy printer at 300$. Medium range are printers such as ultimaker are available around 3000$. Top end printers, the ones with prices ‘on demand’, easily go over several $100 000. As with most products: depending on the options and specifications a whole range is available in between these three examples.

Usage

FDM has a very broad field of application. It is a very popular technology for makers but also in several industries it is used a lot. Very often to solve very specific problems. Prototyping and product development is one important field of application. The printed part has a quite decent finish, has a certain strength and can withstand temperatures to a certain degree making it ideal for engineers to test them. Not only prototyping but also specific helping tools in manufacturing. Ultimaker for example advertises with Volkswagen using its printers in this article.

Materials

This popular printing process allows for many different. The most common are ABS, PLA and polycarbonate. PLA (polylactic acid) is biodegradable and is popular due to it being non-toxic. There are also dissolvable materials such as PVA (Polyvinyl Alcohol) which is used for supports (more on that in an upcoming article). Leaving the result in water for a day completely dissolves the material. Some FDM 3D printers can have two or more print heads that can print in multiple different materials or colors.

img credz: pixabay.com

Nice, you got a 32.0% @trafalgar upgoat, thanks to @jefpatat

Want a boost? Minnowbooster's got your back!

Very good post about FDM printing! Do you use the UM2+ yourself?

Thank you.

Lately not so much. Now I'm mainly experimenting with the UM3 and fine dual colorprinting.

UM3 and dual extruding, that is awesome. I think I will buy the next UM that comes out. Currently I am very happy with my Prusa i3 MK2s.

I don't own them, I use them in the fablab ;-)

Don't think I could spend the money on them. As I said it depends on the budget and requirements. Trade-offs...

There's a new Form2 from fablabs. Planning to play around with that one. Just thinking of a good project (excuse) to play ;-)

Finally I found some 3D printing posts. Didn’t know that I had to search for printing3d. I have the um2+ and it’s a real working horse.

This post has received a 4.43 % upvote from @buildawhale thanks to: @jefpatat. Send at least 0.50 SBD to @buildawhale with a post link in the memo field for a portion of the next vote.

To support our daily curation initiative, please vote on my owner, @themarkymark, as a Steem Witness

This wonderful post has received a bellyrub 15.12 % upvote from @bellyrub thanks to this cool cat: @jefpatat. My pops @zeartul is one of your top steemit witness, if you like my bellyrubs please go vote for him, if you love what he is doing vote for this comment as well.