3D printing: know the limits of the printing process

In my previous article about 3D printing using fused deposition modeling. This is the technology I use most and is most popular in the maker community. Very often new people think they can print anything. It happened the other day in the fablab. A new guy came in asking if we could help him to print a design he made, needing it the next morning for school. The expectations were way too high for several reasons.

Printing time

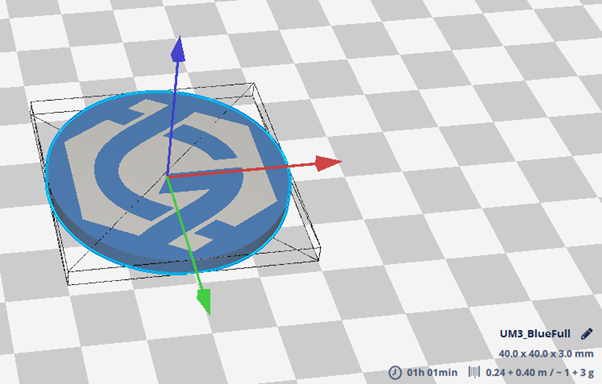

3D printing takes time. This off course depends on the size and complexity of the model. Even so, printing time is mostly underestimated by newcomers. The new guy came in at 8 pm knowing the fablab closes at 10pm. The software we use gives an indication of the weight of the print and the printing time. In his case the indication was 8 hours which he obviously didn’t expect. To give you an example: this is a screenshot of a design I’m working on. The model has a diameter of 40mm and a thickness of 3 mm. On this printer, with default settings this takes an hour to print. And that’s with default settings. The printing time indication is in the right bottom corner:

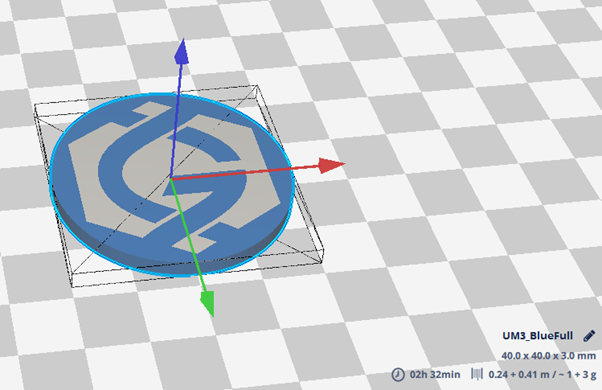

Going with extra fine settings this goes up fast to 2.5 hours:

Detail

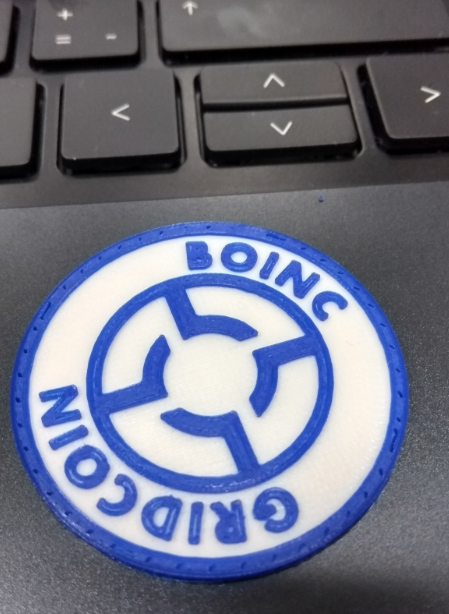

The achievable detail depends on the printing technique and the settings. But also the design itself can influence this. This is often a matter of trial and error because most of us don’t do this for a living and it requires experience with the tools at hand. Again I will show some examples of the coin. Every example has the same dimensions and is printed on the same printer. This first picture shows the text on top of the white, in relief.

And now with more detail:

This is the top of the print, the white got printed first and the blue was printed on top. Now, the same model, the same size but with the letters embedded in white and at the bottom of the model, so printed first.

The difference is huge. In this printing process the first layer is often the most difficult one. It has to stick to the buildplate well and there are several factors that influence this. Build plate temperature, leveling, how clean or well treated the buildplate is, the use of a brim. In the example above the white gets printed first, the detail is too high, the filament doesn’t follow this detail well in a first layer. Then the blue is printed a couple of minutes later and the filament again has the same issues but this time in an already imperfect white print. The next picture is from the same model but this time the top of the print. Although this is not text notice the detail is a lot better.

Supports

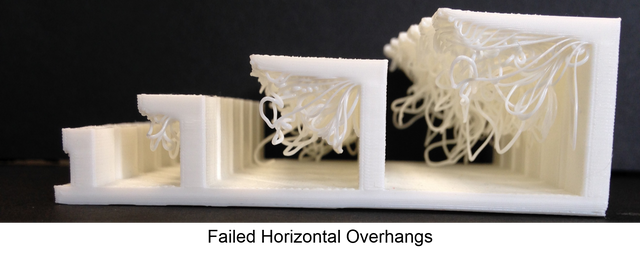

This printing technique can not print in the void, it needs to print on top of something else. Gradual widening the model from bottom to top works within certain limits. A typical example I refer to are the following pictures from The inovation station

And the result:

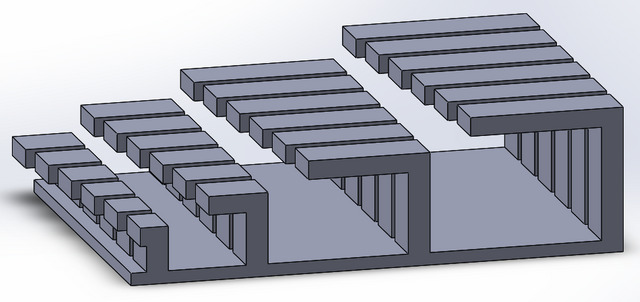

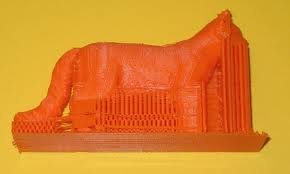

To prevent this from happening we print a supporting structure which can be removed once the print is finished. Such as in this example:

Prototype first

These are just some examples of ‘mistakes’ I see a lot. There are other more advanced tricks but those go beyond the scope of this basic article. My advice is always: take your time and experiment. Don’t expect the print to be perfect right away if you have high standards. The pictures of the coin above are all from experiments, to see how far I can go with this design. Even though I have quite some experience it’s still worth to fiddle around with the setup.

The most annoying part is watching, waiting and not leaving the house :-(

I don't have the patience for that, I take the gamble after the first layers.

img credz: pixabay.com

Nice, you got a 19.0% @trafalgar upgoat, thanks to @jefpatat

Want a boost? Minnowbooster's got your back!

The @OriginalWorks bot has determined this post by @jefpatat to be original material and upvoted(2%) it!

To call @OriginalWorks, simply reply to any post with @originalworks or !originalworks in your message!

I really got to learn the 3D printing world more. I was born with three fingera on my right hand! It is pricey to have something made. 3D printing is the future that is for sure!

It's here to stay for sure. And not only here, it's even used in space.

That's awesome!!

This post has received a 13.43 % upvote from @buildawhale thanks to: @jefpatat. Send at least 1 SBD to @buildawhale with a post link in the memo field for a portion of the next vote.

To support our daily curation initiative, please vote on my owner, @themarkymark, as a Steem Witness

This wonderful post has received a bellyrub 6.59 % upvote from @bellyrub thanks to this cool cat: @jefpatat. My pops @zeartul is one of your top steemit witness, if you like my bellyrubs please go vote for him, if you love what he is doing vote for this comment as well.

" In this printing process the first layer is often the most difficult one."

Man this is the truth! I'm printing a large piece in sections for a friend of mines wedding. When I started the third piece of a 16 piece print a cold front hit. I usually keep my printer in my garage. Suddenly the whole support area kept slipping off of the bed. I really don't want to use rafts on this so I brought the printer inside. Im going to have to make a plastic tent or something to trap the heat from the printer so I can keep it out there.