Knives (handmade) 101 #4 Full Custom Build

So, for this session, I would like to show you what the procedure for a full custom build looks like in my workshop.

First of all, what is the difference between a hand-made knife and a full custom (hand-made) knife?

Well, both knives are made by hands, and both are hand-made, the main difference is that when I'm building a hand-made knife I don't consult with a customer or I don't even have a customer but am building a knife based on my own design. There are, of course, different grades; I could be building based on my predefined design, based on what I've built in the past, it could be I'm making a knife based on a new design, trying out a prototype or just letting the work take me wherever and just playing along.

The full custom knife, on the other hand, means that a customer has come to me with a request for a specific knife.

Most knifemakers don't like full customs - because of reasons - and I'm not an exception. It's a long process of back and forwards until ideas from a non-knifemaker meet the reality of a knifemaker in the point in spacetime continuum where both the customer and the knifemaker are satisfied. As you can guess that point is not reached easily.

This one was actually an unusually pleasant build and I have a relatively good documentation from start to finish so I will use it as an example. But, please, keep in mind the process is more often than not, not this smoot.

It all started with me posting one of my knives on 9GAG where one of the man of culture have shown interest in my knives and we started chatting which eventually lead to him asking me if I would build him a knife for a Christmas present to his mom.

If I'm not mistaken, this was in October, so seemingly enough time for a knife build, but really not too much. And honestly, I was reluctant to take the order.

The background story was that his mom has a knife that she really likes to use, it's comfortable in hand and it's her favourite knife in the whole world. The problem was that the knife was a pain in the ass to sharpen and didn't hold the edge long. This is often the case with stainless steel (I will cover this problem in some future post).

Anyhow, I did eventually agree to do it and here is the, somewhat simplified, process from start to finish.

To make things more narrative I will call the customer Bill - that's not his real name.

I. The Wishes

Bill was quite firm that he wanted the exact knife with jus the steel being more, let's say, user-friendly.

I did try to explain, that if you going full custom, and are already paying for it you might as well go nuts and get something you couldn't get anywhere.

But he was consistent - I did try, and succeed, to sneak some of my ideas, but that falls under licencia poetica rule and it is to be expected.

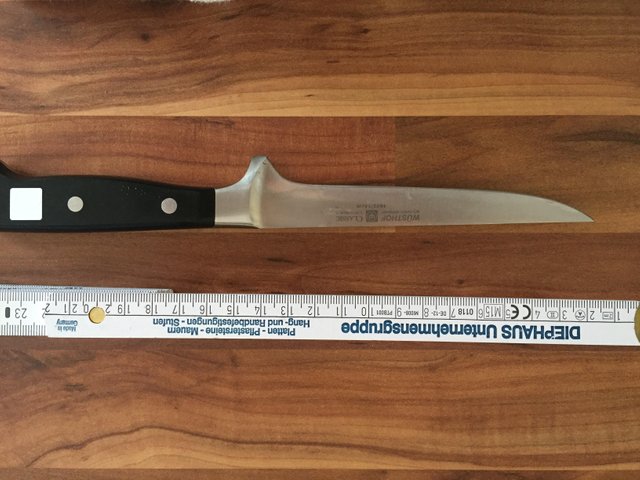

I did ask if he could send me a pic or two of the knife his mom has so I can get the general idea of where to go with my design.

this is what he sent me:

My first reaction was - what the hell did I get myself into? I was supposed to build a knife that is better than WÜSTHOF?! I was sure he'll send me a pic of some under $5 knife his mom bought in a nearby 7/11, but nooo it's a freaking WÜSTHOF.

I guess I could have backed out, but after thinking about it I've said to myself - come on man you can do this.

II. The First Draft

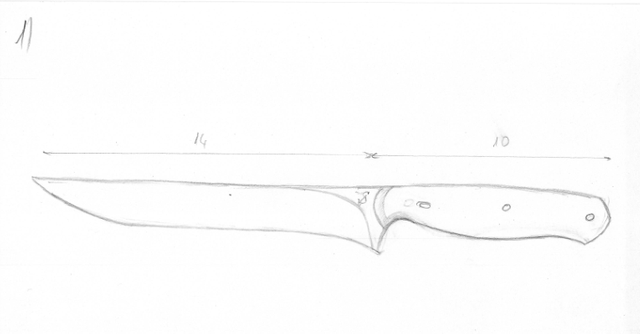

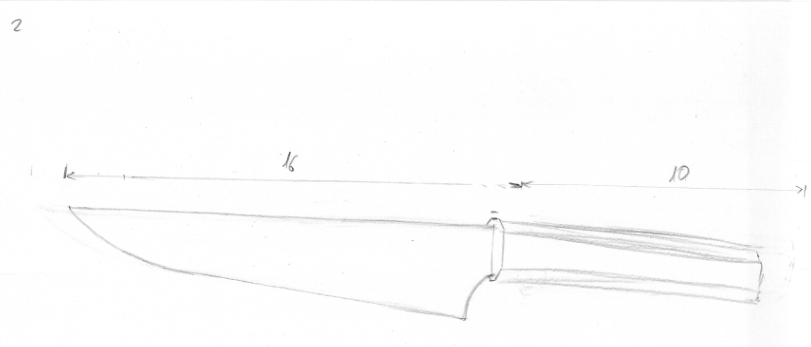

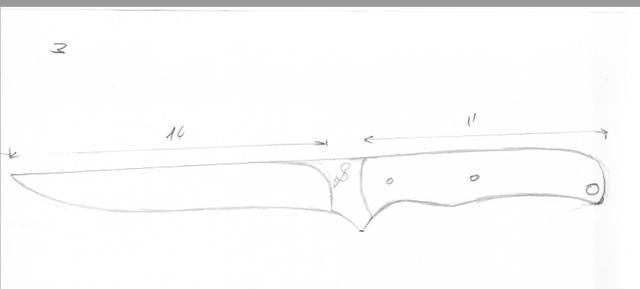

After thinking about how to approach this build I did a few free-hand sketches and after some additional screening sent three of them to Bill.

Bill took the sketches to his mom, and then got back to me with million questions, about curves, recurves, handles, materials for handles, pins, finishes and all the little tweaks that I was casually mentioning, knowing that everything I do bring up will generate 10 more Q. This lasted for 10 days or so.

We finally, settled on a slightly modified design shown in the first sketch with wooden handle, brass hardware and a hand-rubbed satin finish.

III. The Build

You can see the first attempt just cut-out with the stencil still glued on on the pic above.

After the heat treatment, I wasn't really satisfied with the results so I did the second one.

Well, I wasn't really too thrilled with that one also - it was probably the WÜSTHOF warning in the back of my mind that kept sounding off all the time.

You can see both of them in the scrap pile on this pic.

To cut this short, the third time was the charm.

You can see what will eventually become a knife cooking to the far left in my forge.

This is what it looked like strait of the grinder. You can see it was still a bit rough around the edges.

This is just after I've glued on the handle scales.

This is the handle after rough profiling.

And this is the finished knife just before the sharpening.

IV. Done

Eventually, I was able to ship it on time and both Bill and his mom were thrilled with the knife.

Honestly, even though it was a rather stressful build, especially at the very end where it was close to the deadline and there were so many things to go wrong, I was really happy with how it turned out.

Here are a few "better quality" pics of the final product.

As always, if you have any questions or you just want to say something or anything, feel free to leave a comment below.

Thank you for your support and see you soon.

Nice post and great work!

Personally for kitchen knives I use stainless steel, AEB-L is my favorite. The tempering process, however, must be done in a temperature controlled oven.

WÜSTHOF knives are excellent tools but steel is a modified AISI 420 ... 90% of manufacturers use this steel, they have a hardness of 54/56 HRC. If I'm not mistaken you use a carbohydrate, for the hardness and tightness of the thread are exceptional.

Greetings, nicola

PS you have an instagram or FB contact?

Thank you - much appreciated.

The problem with me doing stainless steel is that I don't have the equipment to do the heat treatment myself so I have to send it out. That is OK, but it kin off takes the process out of my hands and I don't really like that. I'm not saying I don't do them, I do but I really like high-carbon steel both for working with it and for using it in the kitchen.

I do plan to make my workshop a bit bigger this year so an electric heat-oven is something I would like to add to it. I will probably make stainless a bit more common then. But high-carbon will still be my first choice. :)

Insta: docsmithknives

Well done ;)

Thank you and welcome to Steemit ;)

Drop me a note on Insta if you need any help. The direct msgs here are usually done via Discord- and I haven't quite gotten into it.

Well you realy know a lot about knives :D

I am by no means a master or professional it's just a hobby that I really enjoy, so I did pick a few bits of knowledge here and there.

Thats a really pretty knife. I too, prefer carbon steel, but recently I actually worked with sandvik 12c27 on a project similar to this , in that it was custom build together with a customer. I actually managed to do a successful heat treat without an oven, but it was probably more luck than anything else. In the meantime I have bought an oven (because I needed it for investment casting) but it is fairly small so no more than 20 cm on the diagonal.

Thanks hippie,

LOL - I've tried that with D2 and wasn't lucky at all. I did get a nice batch of knife-like objects added to my wall of shame :)

20cm is a bit short for knives - did you buy it or make it?

I bought it. My dream is to buy an evenheat kf 49.5 extreme depth oven then I would be able to heattreat longswords in it. I dont really need that , since swords are always made from carbon steel so my present setup it adequate, but its still nice.

Hahaha, that's a reeeeeeeely big oven. Sure, it would be cool to have it but it is a bit of an overkill. Then again, if you really wanna super fine-tune the temper on your swords, something like this would be ideal.

well done

Thank you, much obliged.

This post is amazing! Thank you for your time and effort!

You are very welcome! I do have a hidden agenda - my goal is that by 2020. every steemian has a handmade knife in his/her kitchen ;)

Your knives are gorgeous. Make my Shuns and Wusthoffs look boring.

Wow, that's actually one of the best compliments I've ever had. Thank you so much.

@originalworks

The @OriginalWorks bot has determined this post by @docsmith to be original material and upvoted it!

To call @OriginalWorks, simply reply to any post with @originalworks or !originalworks in your message!

Thank you @docsmith for making a transfer to me for an upvote of 1.56% on this post! Half of your bid goes to @budgets which funds growth projects for Steem like our top 25 posts on Steem! The other half helps holders of Steem power earn about 60% APR on a delegation to me! For help, will you please visit https://jerrybanfield.com/contact/ because I check my discord server daily? To learn more about Steem, will you please use http://steem.guide/ because this URL forwards to my most recently updated complete Steem tutorial?

Awesome 👏👏

Follow @aplek