Beer does not kill people

More precisely, the phrase sounds like this: "Beer does not kill people, water kills people." This phrase from the Soviet comedy of 1975.

Last year in my city a beer factory "Kraft" was built. In this regard, the organizers have invited a group of bloggers (sometimes overly active) on an excursion.

The factory has a "strict" skip mode. We were all recorded. As we were told during the further presentation, that after the launch of the plant will conduct excursions. The mode will be amplified. Put the apparatus conducting disinfection. All will wear shoe covers, gowns and hats. Access will not be in all rooms. Extra microorganisms in the production of good beer are unacceptable.

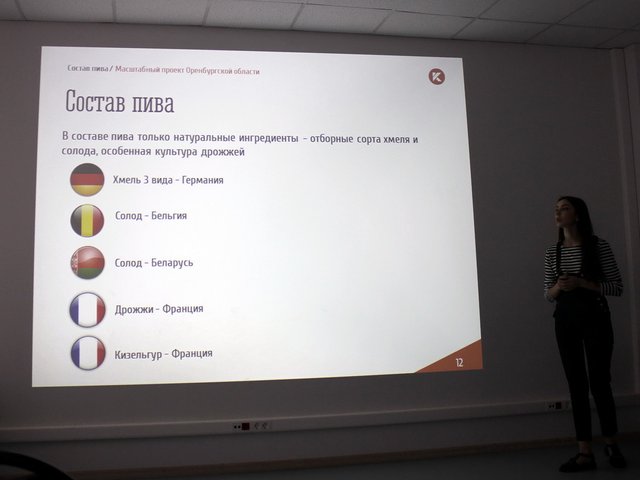

Alena (marketer and PR manager) entertained everyone, answered questions and told interesting facts. She told us about the beer market in the Orenburg region. The fact that the share of Orenburg breweries is negligible, in comparison with large holdings. The fact that originally Kraft beer will be bottled only in kegs, with an approximate price per liter of about 80 rubles. It is planned to produce 22,000,000 liters of beer per year, which will be sold throughout the region. While nothing can be said about the sale outside the region. In the future, the plant plans to produce other types of beer, kvass and water. We learned the volume of what ingredients will be prepared beer and where these very ingredients are taken. Unfortunately, there are no Orenburg producers and Russian manufacturers among suppliers, as they have not been able to agree yet.

We were shown the laboratory, which is headed by Svetlana Gorilaya. The laboratory is equipped with modern expensive equipment, which allows you to track the quality of components and products.

All laboratory glassware is exhibited on the shelves according to international requirements. At present, not all the furniture is assembled, there are not enough employees, and therefore the laboratory looks empty.

Usually on the roof of bloggers are led towards the end of the tour. This time, the organizers decided to start from the roof. They immediately boasted capacities of cylinder-conical tanks for the fermentation of 60 tons.

Preparation of seats for the installation of the second stage of the CСT.

The plant is located near the city. I immediately had a question about the quality of water from a 120-meter well, which was drilled specifically for the plant. As the employees of the plant assure, before the construction was started, laboratory tests of water were carried out. Water meets all requirements. And even, it is cleaner than in other places in question. In addition, the plant has installed water treatment equipment that will make this water even better.

The territory has its own boiler room.

Alyona asked not to photograph her in a helmet. Well, of course I will not ...

"Smoking area"

Malt silage - stone cleaning, metal cleaning and all sorts of other cleaning. And this despite the fact that malt suppliers supply the already purified product.

The first photo shows the brewing orders. In each different stuffing, for different actions. In some malt it is mixed with warm water, in another it is boiled, in the third it is filtered, etc.

All equipment is assembled under the supervision of the German specialists of the equipment supplier GEA Brewery Systems GmbH. There were two of them, but one went home (his work is finished), but the most experienced one was left - Stefan. As he himself said, he has been working on projects in Russia for 20 years and is able to communicate with Russian workers. He says that Russian experts are better than German specialists, because they are universal and cheaper. Stefan could not say anything about Orenburg, because "he works a lot, and off time tries to lie on the bed" - the poor guy is tired.

Everything is in the dust and not all finishing is finished. But before launching everything will be washed clean both outside and inside. The whole complex is equipped with an internal cleaning system. Cleaning is performed both before starting the equipment and after the batch production. From the chief technologist Roman Tsyplakov learned that the use of preservatives in the production of beer is prohibited. The shelf life of beer in 6-12 months is achieved only by cleaning the raw materials, tightness of the entire line and high pressure in the system. When oxygen enters the beer, the expiration date is calculated in days. As my colleagues joked, after I told them this: "When beer gets into PET, the lifetime of beer is counted for hours ... Nobody will let him live for a whole day ..."

The modern beer factory gives the impression of a realm of stainless steel and twisted pair. Stainless steel is understandable, and UTP is so much because the whole complex operates on the basis of OTAS basic, which is based on Windows 7.

Near the end of the tour, one of the bloggers, as the most experienced in beer, was offered to taste 2 different beers with closed eyes. By condition, one beer was supposed to be Russian, and the other one was foreign. It was necessary to say which is better. Misha liked the second option, he found some fruit shades in it and was sure that it was Edelweiss. It can be seen from the photo that both beers were domestic, only the name is different. The psychology of the Russian people - foreign goods is always better. Although Misha assured that the second taste exactly the same Edelweiss.

At the end of the event, Alena distributed the preforms of PET filled with malt to all participants. At home I opened it - it smells delicious. It turned out that the rabbit Dusya is very fond of such a delicacy. She was ready to perform any team for a small portion. So if someone has a rabbit, then you know - a rabbit will give his soul not only for raisins, but also for malt.

At the time I'm writing this post, the plant is already working. The stores already sell beer. People buy this beer and respond positively. Soon I plan to visit the plant again and see how it works during production.

The picture is taken from the site of the plant.

In Russian, this post can be read on my page in LJ.

DISCLAIMER: dropahead Curation Team does not necessarily share opinions expressed in this article, but find author's effort and/or contribution deserves better reward and visibility.

to maximize your curation rewards!

with SteemConnect

12.5SP, 25SP, 50SP, 100SP, 250SP, 500SP, 1000SP

Do the above and we'll have more STEEM POWER to give YOU bigger rewards next time!

News from dropahead: How to give back to the dropahead Project in 15 seconds or less

Greetings! I am a minnow exclusive bot that gives a 5X upvote! I recommend this amazing guide on how to be a steemit rockstar! I was made by @EarthNation to make Steemit easier and more rewarding for minnows.

Great and interesting post!!

Thanks!

rusteemteam!