Utilization of Rice Husk as an Alternative Fuel to Gas Stove/Cooker

"Utilization of Rice Husk as an Alternative Fuel to Gas Stove/Cooker"

In third world countries where majority of the people struggles with monetary problem, one major difficulty other than foods and shelter is energy crisis and the increasing cost of fuels. Because of this, people tend to exploit renewable natural resources such the solar energy, wind energy and natural biomass products. However setting up equipment to process such would also need significant amount of money. Therefore the challenge is to design and develop a device which is cheap yet effective in providing clean energy.

In the Philippines, majority of the people could not afford to use liquefied petroleum gas or LPG as primary fuel for cooking. Most would rather use firewood on their cooking as most people find it more effective yet inexpensive. But the problem with this is that if majority of the people would adapt into it, then the carbon emission due to incomplete combustion of fuel would accumulate and would possibly be contributed to the serious issue of environmental pollution which is regarded as primary cause of global warming.

Today, as the advancement of technology is inevitable, people especially from Southeast Asia and Africa have designed a gas stove which utilized rice husk as the main fuel. Rice husk which is the by-product of rice is certainly a plentiful waste present on some parts in almost all countries in the world. Most of which are left unusable in rice fields and roads while others would just dump and incinerate them as people find it more straightforward. So instead of throwing away these waste materials, why not utilize it as an alternative fuel?

If we search the internet for gas stove which utilized rice husk as fuel, we’ll find various research papers regarding the equipment. This low-cost and clean-burning equipment is primarily designed and developed for small domestic rural households which have direct access to plenty rice husk waste materials. One ton of rice husk is estimated to have a direct energy conversion of about 23 tanks of 11 kilogram LPG fuel which could significantly offer an alternative solution to the increasing cost of conventional fuel source for cooking.

There are basically two types of this equipment, the batch type and the continuous type, and the most common design is the latter. Continuous type is mostly developed as it is more reasonably smooth as it can be operational without entirely discharging and reloading the stove with rice husks. There are various designs for the rice husk fueled gas stove but the conceptual design is almost similar for all. The concept is not really complicated. Take for example the innovative design of the Eastern University in Chenkalady, Vanthrumoolai, Sri Lanka.

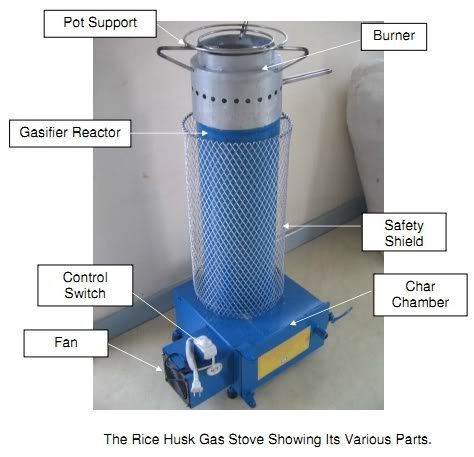

Their design for rice husk gas stove is mainly consist of, 1.) Fan System for Air Blow, 2.) Control Switch, 3.) Gasifier Reactor, 4.) Pot Support, 5.) Burner, 6.) Safety Shield and 7.) Char or Carbonize Chamber. Judging from the figure, the main body of gas stove is the Gasifier Reactor where the burning of rice husk in a limited air flow takes place. According to them, the reactor is a cylindrical iron sheets coated with zinc and has dimensions of 0.6 meters in height and an inner diameter of 0.2 meters with 0.03 meters cylindrical thickness. An annular space filled with a mixture of cement and rice husk acts as the thermal insulator or refractory to minimize heat loss from the reactor. Aluminum net was also attached in the body for safety purposes.

To better understand the concept, the rice husks are fed unto the inlet of the burner and are locked by a stopper to prevent it from falling into the char chamber. The rice husk is then burned using a piece of paper. An air from secondary holes in the burner and from the fan system is then blown into the reactor to aid the fire and the fuel to produce bluish fire as a result of complete combustion. By controlling the amount of air, gasification with complete combustion minimizing carbon emission could be achieved. As the combustion zone moves downward, burned rice husks are left inside the reactor in the form of char or carbon. This resulting carbon reacts with the air which is supplied by the fan system producing combustible gases.

Same concept is also being developed in the Philippines, particularly in Central Luzon State University in Nueva Ecija. The rice husk is also aided with fan system to blow towards the reactor chamber which is necessary to achieve partial if not complete combustion resulting in creation of bluish flame. And according to the authors of these studies, the advantages such as low carbon dioxide and black carbon emission, fast fuel ignition and nearly no smoke release during operation are significant to minimize carbon emission which is the primary cause of global warming.

And as a proposal, for better thermal insulating Gasifier Reactor, I suggest to replace the use of metal sheets for the reactor or body. Ceramic products are better thermal insulator than metals and cement, and other than that, ceramic raw materials are naturally abundant in nature and therefore are economical when this equipment is commercialize. And during my academic years, I’ve observed a ceramic gas stove fueled by rice husk during one of our experiments but I didn’t appreciate its efficiency until now. However, one disadvantage that I’ve perceived about ceramic stove is its heaviness in weight.

THANK YOU FOR TAKING THE TIME TO READ MY POST

Classification of Refractories According to Physical Form, Method of Manufacture and Chemical Nature

Ceramic Application to High Temperature Furnaces as Refractory Materials

A Quick Overview of Ceramic Glaze to Ceramic Products

Electric Mosquito Net with Silica Fabric (Ceramic) Insulator

References:

1.) Rice Husk Gasifier Stove by MicroEnergy International GmbH

2.) Designing a Cooker to Utilise the Natural Waste Rice Husk as a Cooking Gas by Fernando PR, Karthika U, Parthipan K, Shandarabavan T, Ismail R and Jeeva A

3.) Design and Performance of a Household-size Continuous-flow Rice Husk Gas Stove by Alexis T. Belonio, Emmanuel V. Sica, Francisco D. Cuaresma

That's the fuel for the "kugon" a clay stove used in the provinces, esp when there's no electricity. Used instead of charcoal.

You've used it lola? If I remembered correctly kugon has high emission of carbon.

Will the provinces think of carbon emission during those days? Let alone know of the words lolsss

Free yan..from sa kapitbahay!

Curating steemph

My support,

👀

Thanks a lot :)

Welcome,

These are fuel alternatives every nation across the world should consider, not only those from "third-world countries". Cleaner energy in this time and era will do everyone a lot of good. Thanks for the info.

I agree! We should develop technology to utilize natural biomass as source of energy.