Enhancing Low Thermal Insulating Property of Porous Ceramic Raw Materials

"Enhancing Low Thermal Insulating Property of Porous Ceramic Raw Materials"

The thermal insulating capability of ceramic materials has long been considered to be excellent and efficient. It has already been proven and tested and are in fact are widely used as primary components of any kind of insulations both as thermal and/or electrical. One basic foundation of this property is due to its micro-porous structure which can be observed using Scanning Electron Microscope or SEM. Additionally, its capacity to withstand high temperature makes it a perfect insulating component.

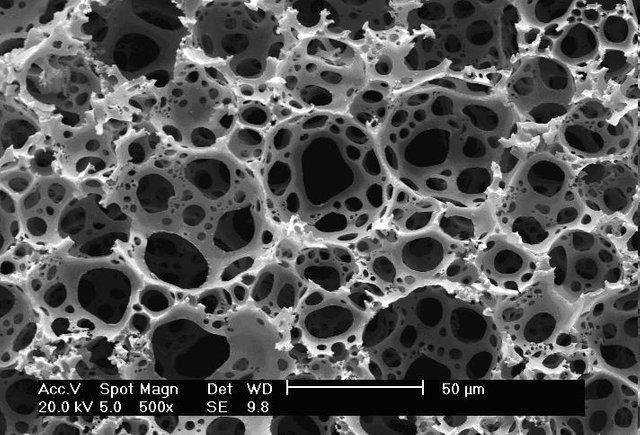

Heat transfer is basically influenced by heat conduction and convection. Therefore, if these conduction paths are limited and reduced to as low as possible then the value of thermal conductivity is decreased significantly. These pores spaces create empty spaces within the body which restricts direct straight conduction path of heat coming from higher temperature region to lower temperature region of the material.

However, if we consider the trapped air and other gasses present on those pores spaces then heat transferred via convection may increase as the pore volume increases, because in large enclosed space, greater convection currents are formed. Nonetheless the trapped air and other gasses inside those pores spaces could still act as thermal insulator thus preventing heat conduction to the great extent.

Hence, if optimal quantities of pores space are controlled, well-organized and arranged unvaryingly then insulating power can be considerably increased. With limited budget and equipment, this could be achieved and be positively done through series of thorough experimentation, research and patience. Moreover, numerous factors in conducting this investigation should be considered.

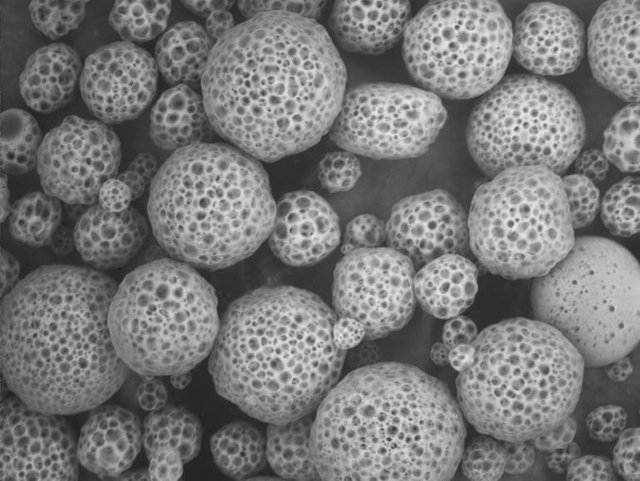

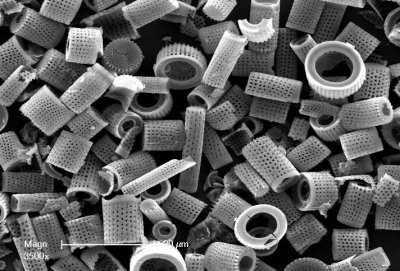

The first step in doing this is to investigate raw materials with porous microstructure with high thermal resistance. And with this, the excellent candidates are ceramic raw materials. One example is which exhibit these properties and structural integrity is the one which we used in our research way back 2013, diatomaceous earth or simply diatomite.

Then again, numerous factors are to be considered before engaging into this kind of experiment. The factors that we need to consider first are availability and supply. Especially for big industrial companies who are into this, it is very important to quantify and calculate expense, profit and most importantly sustainability. On our part, out of three raw materials that we choose from, we picked diatomite as available and abundant near our area.

Diatomaceous earths or diatomites are technically siliceous sedimentary rocks which formed and originate from fossils of single-celled organisms called diatoms. These fossils are basically amorphous which means that it has no definite shape and form. Due to its unique properties and distinct microstructural geometry, this raw material has wide range of industrial application which include as primary component for ceramic filtration products and lightweight aggregates for paints and plastics.

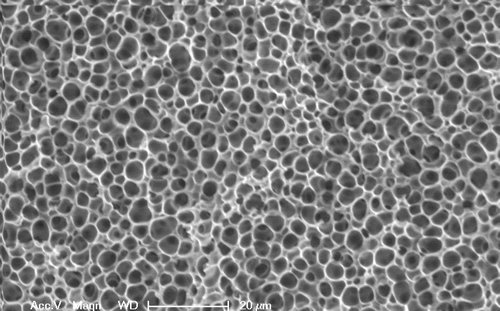

As primary thermal insulating component, it is important to enhance its low thermal insulating capability. One certain property which influenced particulate materials in terms of thermal proficiency is its particle size. There are various method in determining the particle size distribution of certain raw materials, one is by wet sieving method. As constituent, uniform distribution is important thus the size and shape of powders which has direct influence to the compaction properties and homogeneity of insulating materials is to be considered.

Small particles add up easily with other constituent and have better distribution and uniformity than larger particles. To determine this, particle size distribution through wet sieving method is to be done. Samples are screened under running water at a sequence of various sieves with different mesh size. Residue or those who failed to pass within a certain screen is determined by weight.

Subsequently, one important thing to be determined is the calcination effects in certain raw material or in this case as example is the effect of calcination in diatomite. The primary purpose of calcination is to reduce diatomite’s density and thermal conductivity. These two properties are proportional to the calcination temperature. However, optimal temperature is to be carefully determined as too much temperature can destroy the microstructural integrity of diatomite.

Hence calcination in this matter only decreases the density as well as increases purity of certain raw materials without ruining its porous microstructure. Obviously, it is done at lower temperature where there will be no phase transformation than will occur. So basically, primary loss on ignition or LOI during calcination is due to removal of volatile materials at much higher temperature than the usual.

Based on sources, calcination of diatomite at 1000 degrees Celsius relatively destroy its microstructures and partial vitrification can be observed. At higher temperature about 1100 degrees Celsius, the geometrical structure of diatomite completely disappears. On the other hand, calcination of diatomite at 900 degrees Celsius for 3 hours perfectly retained the geometrical microstructure of diatomite while improving its porosity which could be observed using SEM.

THANK YOU FOR TAKING THE TIME TO READ MY POST

Utilization of Local Clay Material in Fabrication of Ceramic Earthenware through Slip Casting Method

Effects of Lightweight Ceramic Materials as Fillers for Paint to Reduce Heat Entry in the Building

High Temperature Superconductive Properties of Ceramic Materials

Advance Ceramic Applications to Automotive Industry

Advance Ceramics Application to Electronics Industry

An Overview to the Manufacturing Process of Flat Glasses

Reference:

Effects of Calcined Kapatagan Diatomite as Filler for Commercial Paint on the Heat Entry by researchers Engr. Christian Volter G. Ranada, Engr. Janine Noelle Destura and Prof. Ivyleen Bernardo-Arugay, MOE (thesis adviser)