Effects of Lightweight Ceramic Materials as Fillers for Paint to Reduce Heat Entry in the Building

"Effects of Lightweight Ceramic Materials as Fillers for Paint to Reduce Heat Entry in the Building"

When you have read my recent articles, ceramic materials are known for their excellent thermal insulating properties. No wonder that most thermal insulating materials are usually made out of ceramics. During my academic years, as a partial requirement to fulfill my degree, I, together with my colleague have studied the use of hollow materials as additives to local commercial paint and have investigated its thermal insulating effect to the heat entry of enclosed chamber which comes from direct sunlight.

In fact, there have been so many existing studies developing the use of these lightweight ceramic materials as additives to paint just to obtain thermal insulating properties. Aside from using electric ventilation, the use of these materials is considered as one of most economical yet very effective way of reducing the heat conduction into a building. It has already been developed for decades throughout the world and we are honored to take part with our simple experiment.

The primary objective of the experiment was to produce an insulative paint using a local raw material from Kapatagan, Lanao del Norte to reduce the heat entry of a specified enclosed chamber via conduction. Furthermore, we also aimed to significantly reduce energy consumption from installed cooling system in the building or of any household. We also consider the use of light-colored paint.

In our case, we used local diatomite as filler to particular local commercial paint. Diatomite is lightweight sedimentary rock with white color which is containing of mainly siliceous fossils of an aquatic single-celled organism called diatom. It has a wide range of industrial application due to its unique properties. Such applications include as raw material for brick production, lightweight aggregates and of course as filler to paints and plastics.

Properties of diatomite including low thermal conductivity, small heat mass, light weight and resistant to high temperature are due to its micro-porous structure which is also very advantageous to our study. Theoretically, the thermal conductivity of the paint is reduced because its conduction path is restricted by the presence of various pores space of diatomite. Additionally, the existence of air and other gases are significant in the absence of convection.

Trapped air acts as thermal insulator by preventing the flow of heat via conduction and thus preventing large-scale convection. Therefore the thermal insulating property of the paint is mainly dependent to the micro-porous structure of diatomite and the presence of air upon its application to surface. Henceforth, the pore space of local diatomite was improved through the process of calcination.

Calcination is the process we used of treating local diatomite raw material to remove impurities such as water, combustible materials, clay and other contaminants which partially covers the pores of diatomite by heating at high temperatures around 800 to 1000 degrees Celsius. The process was thoroughly experimented to avoid destroying the microstructural integrity of diatomite.

We determined the optimal calcination temperature of diatomite without destroying its structure through research and series of calcination at various temperatures and various calcining time/duration. We observed and examined the high-resolution images of the microstructure of calcined diatomite using Cambridge Scanning Electron Microscope (SEM) at different magnifications. After comprehensive observation and discussion we decided and concluded the optimum calcination temperature.

The rheological properties of the commercial paint such as the viscosity and thixotropy were determined using Brookfield DV-E Viscometer with spindle number 5. Subsequently the same rheological properties were determined in the part of diatomite-filled paint. Results were compared and adjustments were made to make sure that their differences do not significantly vary. We limit our experiment to three different mixing proportions of diatomite and commercial paint by volume.

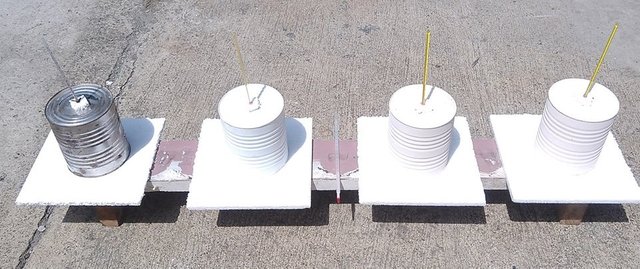

We determined the most efficient mixing proportion by manually applying them to tin cans and comparing their results. We conducted the whole-day experiment for three days. We are limited with not so advance equipment therefore we manually took individual temperatures once every 10 minutes from 9AM to 3PM! We gathered data and use statistics to compare results. Only one mixing proportion stood out with statistical significance. We use it to the next testing procedure.

This time, we compared the efficiency of ordinary commercial paint and our insulative paint in terms of insulating capability on miniature house. Our budget was limited therefore we only conducted the experiment of our paint in a one cubic feet miniature house. The same procedures were done for three days and temperatures were determined every 10 minutes for 6 hours. Data were gathered including the thickness of applied paint.

There were basically two thermometers installed inside on each houses, one is in the center point of the house and the other is installed near the roof inside the house. Results show that local commercial paint have reduced the temperature at the center point and near the roof by 2.54 and 1.32 degrees Celsius respectively while our insulative paint reduced it by 2.80 and 2.34 degrees Celsius respectively. Therefore the insulative paint is 1.02 degree Celsius more efficient than the commercial paint.

THANK YOU FOR TAKING THE TIME TO READ MY POST

High Temperature Superconductive Properties of Ceramic Materials

Advance Ceramic Applications to Automotive Industry

Advance Ceramics Application to Electronics Industry

An Overview to the Manufacturing Process of Flat Glasses

Reference:

Effects of Calcined Kapatagan Diatomite as Filler for Commercial Paint on the Heat Entry by researchers Engr. Christian Volter G. Ranada, Engr. Janine Noelle Destura and Prof. Ivyleen Bernardo-Arugay, MOE (thesis adviser)

thank you sharing :)

Ceramic Power!

Bira bai!

Sounds great & experiment was good to read about.

I wonder what 1.02 degrees x 365 days x 25 (?) yrs means in saved energy costs for heating / cooling?

Probably cover the extra cost of the paint many times over?

Thanks, we did our experiment with much limited equipment and budget. However, the goal there is to determine if there's a significant effect.

Well seems to be a reasonable augment for it to me, unless cost is a major factor

Very good pieces of information

Thank you!

Thanks for sharing @asbonclz

If you wish, please join and support the No smoking Campaign and be a part of that

No smoking Campaign 🚭

Sure! I will support it :)

Have you considered using other additives, like tiny glass beads, or some other insulator?