An Overview to the Manufacturing Process of Flat Glasses

"An Overview to the Manufacturing Process of Flat Glasses"

Glass production industry is a broad industry which caters the fabrication of all types of glasses including glass bottles, fiber glasses, float glasses etc. Each type of glass product has specific production process hence particular machines and equipment are designated for certain glass product which could make one industry to only focus on one particular glass product. Technically, glasses are non-crystalline materials which are often transparent, translucent or opaque with an amorphous structures or meaning no definite shape.

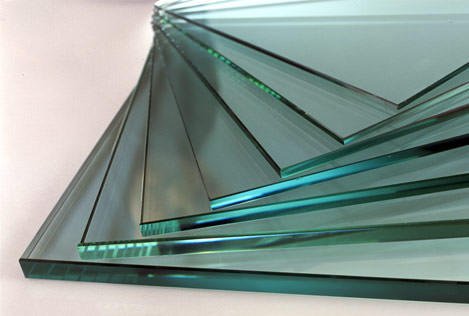

Transparent glasses are of widespread use today either for decoration or for technological and practical use or for everyday custom. We are most familiar with transparent glasses such as glass bottles, cups, table wares such as plates and flat glasses such as household and office windows. But there are also colored glasses which are made with metal oxide components, vitreous enamels, compound impurities etc. through various coloring methods for specific purposes such as tented windows for cars.

The most commonly used and most popular type of glass is the silicate-based glass which is of course made out of the chemical compound silica or silicon dioxide which is the primary constituent of sand. In fact, according to source, the term glass is generally referred to glasses which are made out of these types of materials only. And due to the optical transparency property of silicate-based glasses, various applications are derived from it such as the development of window panes, optical lenses, prisms, fine glassware etc.

Scientifically, glass has broad description which comprises all non-crystalline or amorphous solid structure which exhibits glass transition when heated towards the liquid state. Hence, porcelains are technically glass products which are made out of different raw materials rather than silica, although the primary component of porcelains is kaolinite which is siliceous type of clay. But what made transparent glasses unique? How do these types of glasses (especially flat glasses) differ in production process than any other type of glass in general?

The term ‘flat glass’ strictly includes all types of glasses made in a flat form regardless of the form of manufacture. Most flat glass is produced with a basic soda-lime formulation; a typical flat glass composition or component. They are produced almost exclusively with cross-fired regenerative furnaces.

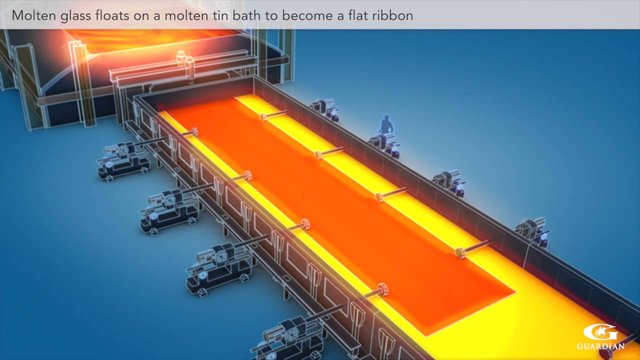

Flat glasses are termed as float glasses as it is usually made through float glass production process. It is mainly based on a simple principle of floating process which basically pours molten glass unto a bath of molten tin to form and produce a blanket of molten glass in which the upper and lower surfaces of the molten glass are influenced by gravity and surface tension to become parallel with each surfaces. This process is accounted for the 90% of flat glass production all over the world.

The float glass production process mainly involved five major stages excluding the batching of materials. During the batching phase, the raw materials are prepared and are mixed prior to melting process. Heavy machineries are used during this process such as trucks and mixing equipment. The primary raw materials such as limestone, dolomite, soda ash, feldspar and silica sand are stored in designated storage and silos before and after batching via conveyor. Glass cullets are also added to reduce consumption of fuel or energy.

The first major process is called melting and refining. In this process, the batch materials are fed unto high temperature furnaces to be melted at temperatures roughly around 1500 to 1650 degrees Celsius. Several processes such as melting, refining and homogenizing simultaneously take place inside the furnace which happens separately at different zones. Generally, from the melting zone, the molten glass flows to refining zone then to homogenizing zone before it come out for another processing stage.

The next major step is called the float bath stage where the molten glass from the previous process flows gently into a bath of molten tin through a ceramic refractory spout at 1100 degrees Celsius to form a partially solid blanket of glass at 600 degrees Celsius. So the glass literally floats over the surface of the molten tin as it is immiscible with molten glass. Thus the glass which very viscous does not mixed with molten fluid tin which primarily influenced the flat surface of the resulting glass.

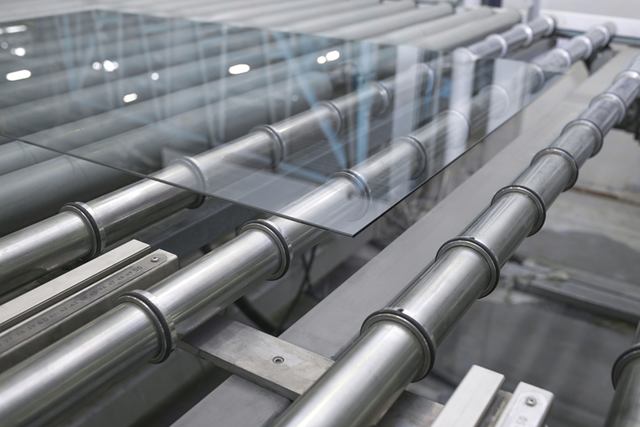

After the float bath stage is the annealing stage which assures that the glass will not break beneath the cutter due to the considerable amount of stress that the glass experienced during cooling. Therefore, to relieve this stresses the glass undergoes heat treatment in a long furnace which is called as lehr to be annealed. During this process, the internal stress of the glass is modified.

After this long process, inspection, quality assurance, cutting and packing of these flat glasses then followed. Although the process is reliable to produce perfectly flat glass, inspection is still necessary to ensure quality. Those who passed inspection and quality assurance are then transported to cutting area. Packing for shipping then commences.

THANK YOU FOR TAKING THE TIME TO READ MY POST

Utilization of Rice Husk as an Alternative Fuel to Gas Stove/Cooker

Classification of Refractories According to Physical Form, Method of Manufacture and Chemical Nature

Ceramic Application to High Temperature Furnaces as Refractory Materials

A Quick Overview of Ceramic Glaze to Ceramic Products

References:

https://en.wikipedia.org/wiki/Glass

Manufacture of Glass

Step-by-step Manufacturing of Float Glass

Float Glass Manufacturing Process

Float Glass Manufacturing Facility

This is more than I ever needed to know about glass production. No regrets!

Glad you've learned from it :)

Mabuhay! Your post has been upvoted and resteemed by the @bayanihan curation group.

Nice description @asbonclz

Intersting post!

Good post, very informative! Keep it up!