Failure! and success, all in one neat package.

There are bad failures and there are good failures. This one was one of the good ones.

Edit: I tried posting from Busy.org and the images didnt seem to display properly. It should be fixed now.

Yesterday I told you about my new printer and in the evening I got it started with a test print. a small skull I have modelled earlier. click here to see renderings of the model as well as a previous print made on my ultimaker2

I have run all the tests that wanhao recommends and I have already had some small troubles. nothing serious though.

First off I set up the printer and tried to connect to it from my laptop.

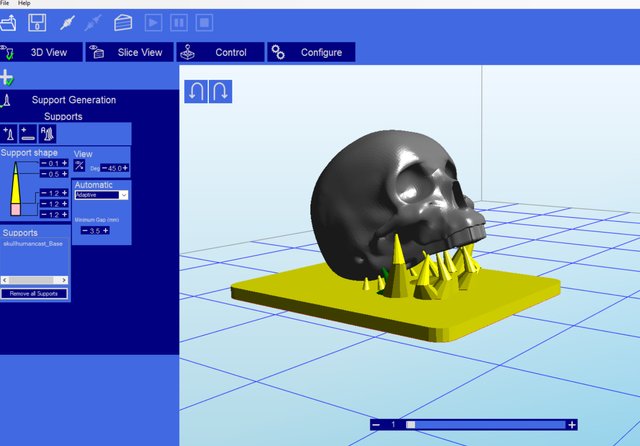

The procedure isnt complicated but the software is still rather WIP. I managed to find the right version of the slicer, which is just a dropbox folder with an .exe file and some parafernalia. There are two version. If you buy a D7 make sure you get the one specifically for D7.

I got the firmware on the printer updated(also a slightly weird experience, sinceyou have to do this through CURA but you need the wanhao version from the same dropbox, and you have to start by choosing a D6 as your machine?!),

This procedure took my the best part of two days, but I was finally ready to do the dry run. After some trouble getting the printer to act as my second screen(you connect it using hdmi and the display that cures the resin, is just a secondary screen with UV backlight)

A dry run is basically running a print without actually running the motors and without resin in the tank. This went well and Yesterday I decided to give it a go with a real print.

I quickly set up my skull and to better test the detail and to get a faster print, i decided to make it quite small. Just 1.5 X 1.5 X 1.5 cm the timer said it would take 1 h 24 min.

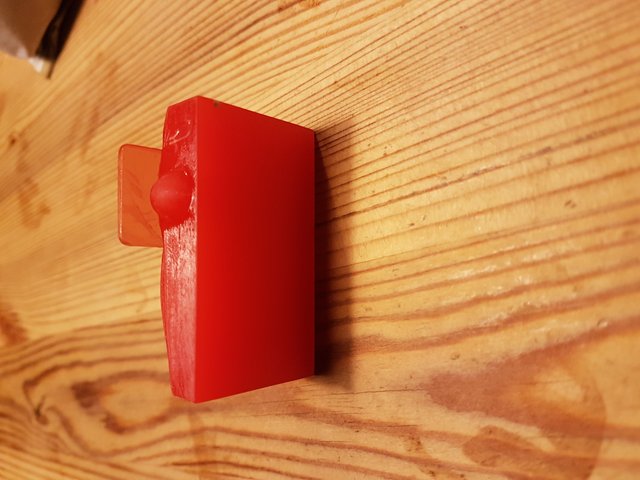

An hour an a half later I could lift the lid and see what had happened underneath. . . . . Well not really a succes I would say.

It doesnt look very much like a skull. Its just a rather large rectangular chunk of resin. I wondered how this could be.

The skull was there alright. it was just embedded in the box. Hmmm .. After thinking a bit, I turned of the printer, and there was my answer. A programwindow appeared on my primary screen. I had tried to turn of the screensaver option and windows had decided to move that window to the secondary screen (aka the printers screen. the one that cures the resin.) Thus, my print was actually a success. I had just not printed a skull but a program-window :-(

Next time I will make sure that all other programs are closed and that I do not tweak anything during the print.

The positive side of things is that the small part of the skull that is visible on the side of the box, actually looks quite good. unfortunately its the backside so it just looks like a small bubble, but it is smooth and nice even though I only ran it on the medium setting(0.05 mm layer)

Im EvilHippie, a compulsive creative and jack o' trades. If you want to know more about me, check out my introduction post here

If you like what you see, feel free to upvote, follow and resteem

or you can check out these recent posts

Microsoft Windows, now in 3D!

I enjoy your 3d printing posts, as I plan to get one myself. I've seen some models that are cheaper and D-I-Y, and after you assemble them you can 3d print some extra parts to upgrade the printer!! The idea is amazing, but the quality of the final product seems a bit lacking (as expected for ~200 euros!)

yes I have had the same thoughts. the first printer I bought was the ultimaker2+. it a quite high end and expensive machine, but the quality and usability is also very good.

This was my attempt at doing the opposite. A form2 (or similar) cost around 4300 euros and a wanhao d7 costs only 600. that leaves a lot of room for other projects and tools , and I am willing to accept quite some frustration on that account . There is a very dedicated community around these cheap products and if you take the time to research the fora etc. its possible to avoid a lot of the frustrating mistakes. Also, you should check out @tarekadam and @fathin-shihab too. They both post about 3dprinting (there are obviously many more but I forgot who)

Thats great, another 3d pinting enthusiast! Upvoted and Following you!