Project: My Own X-Carve Dust Control System - Done!

Habedere,

in this update I want to show the last steps and the finished project.

If you missed the 2nd part:

https://steemit.com/woodworking/@theguymasamato/project-my-own-x-carve-dust-control-system-main-parts

The next step in this project was to paint all parts.

But before I could start I had to do some preparation work.

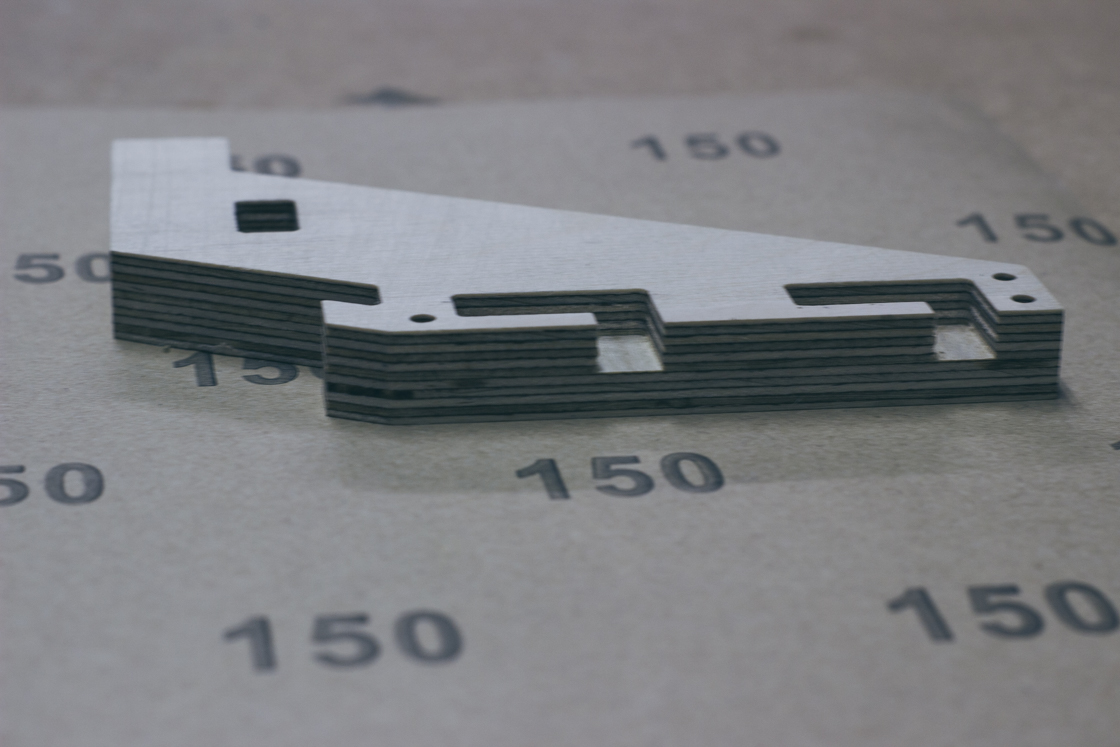

Sanding with 150 grain size and

sealing all parts to protect them against the water during the wet sanding process.

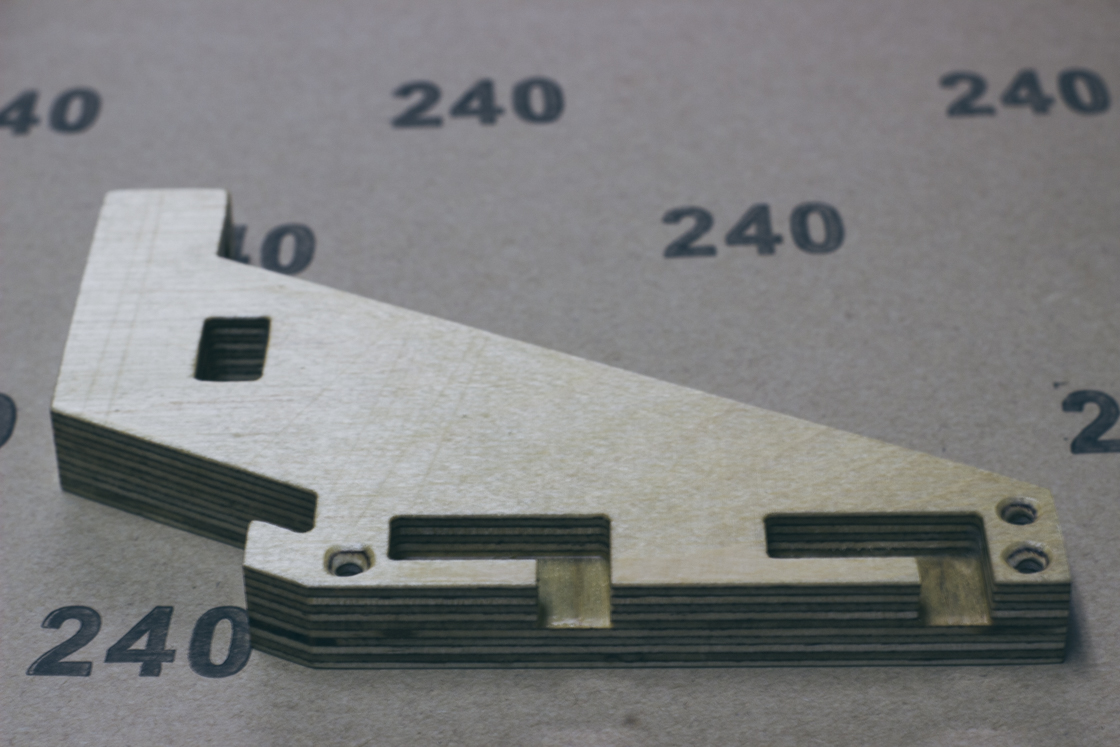

After that I sanded all parts very carefully with 240 grain size.

I'm a very big fan of Montana Cans.

https://www.montana-cans.com/

Not that typical diy/woodworking product.

It has its roots in graffiti and creative artists, but for my it fits perfect to my projects. And the big advantage is that all products are from one manufacturer.

So here you can see all cans that I used.

Primer, texture coating, black and light blue color and a varnish.

Between the different layers I used two grain sizes (400/600) for sanding.

This was the result.

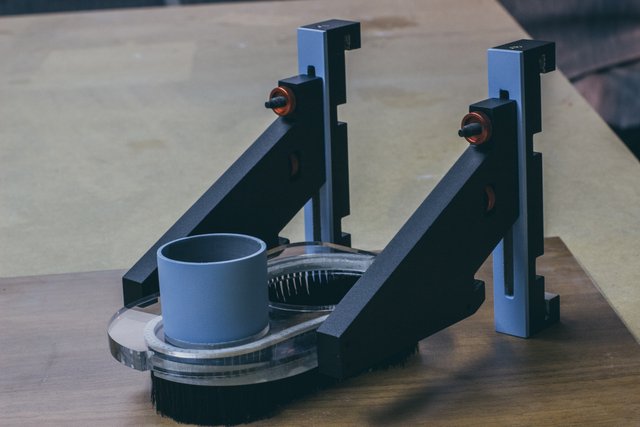

After that I mounted all parts together.

Magnets in the dust shoe mounts and

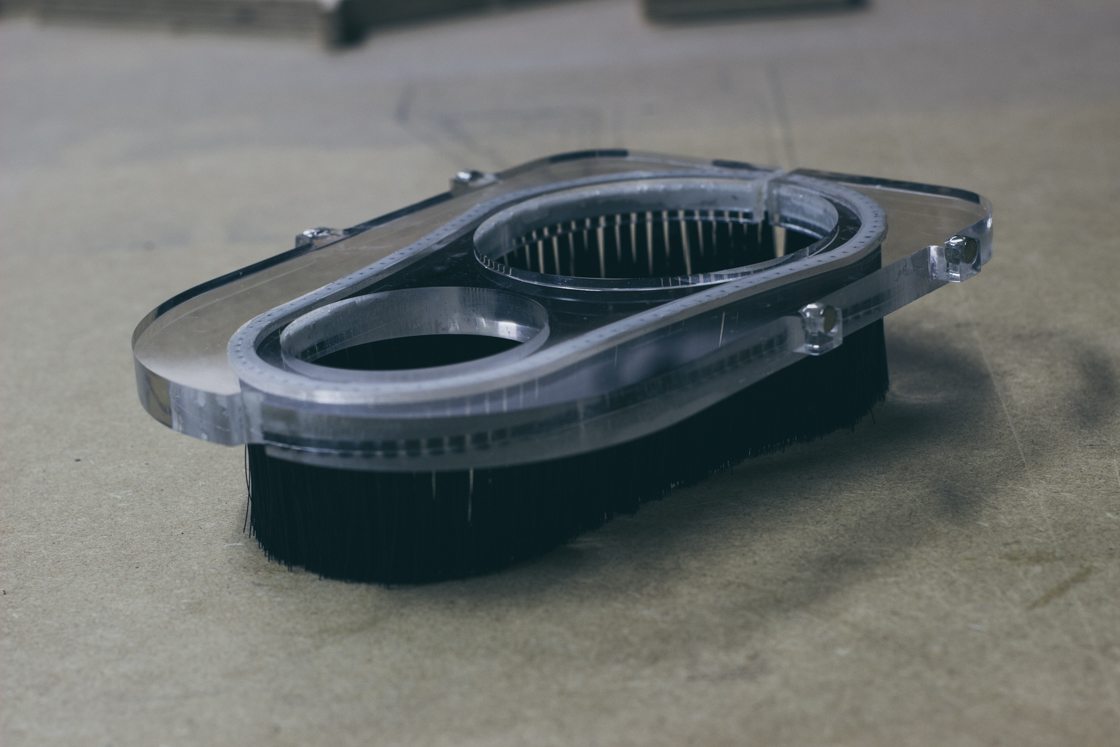

using epoxy to glue in the magnets and the brush strips to the dust shoe.

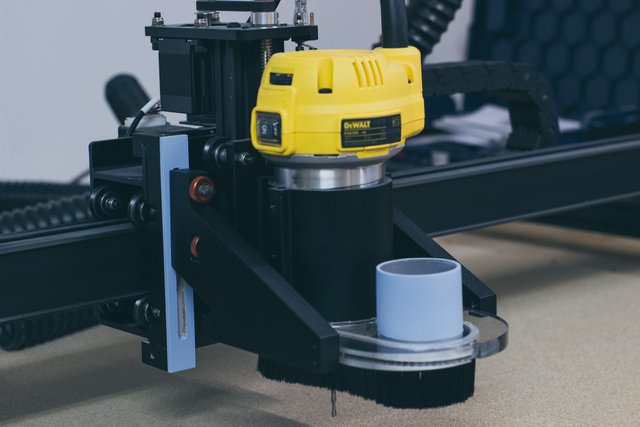

This is my dust shoe.

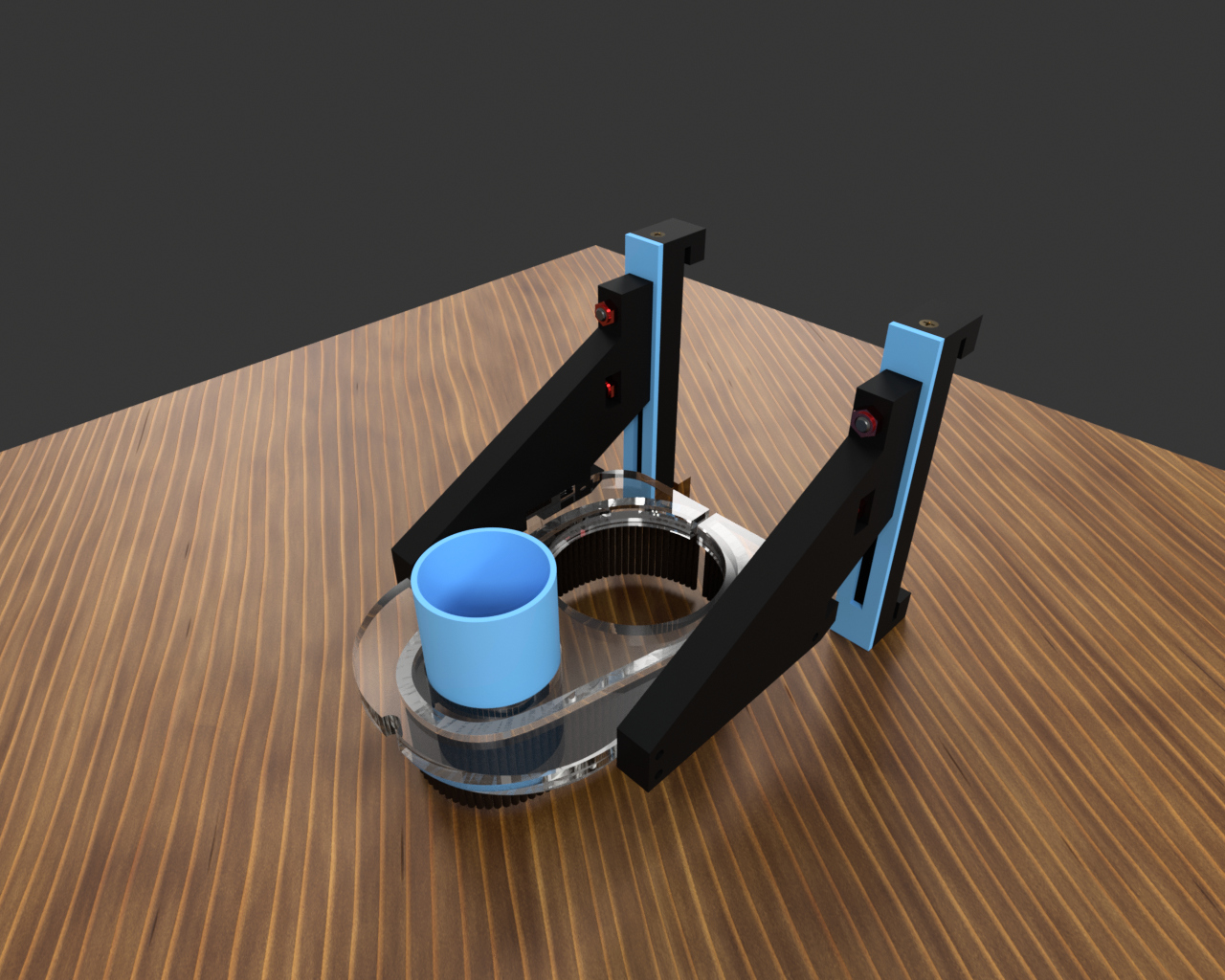

Here the final result and

compared to my render.

And here mounted on the machine.

I've created some animations for you, that you see even more details.

And also a short video on dtube with the dust system in action.

Conclusion

It was a really nice project. Not to big not to small with different materials and tools.

I'm happy with the result. As you can see in the video, I'm not dust free, but the dust is in a small area not all over the place as before.

There is also a problem with the rail system, as you can see on the photos. I forgot to calculate the thickness of the different color layers. So it’s not an smooth movement anymore and the colors layers are flaking off.

That sucks.

To cut a long story short, there will be (in a few weeks) a dust control system 2.0.

Thx for following, liking and commenting on my first project.

Servus and see you with the next project.

Well this turned out great and I can't wait to see what your next projects are! I love the Steemit and date verification at the bottom, that is one way to do it :)

This post was nominated by a @curie curator to be featured in an upcoming Author Showcase post on the @curie blog. If you agree to be featured in this way, please reply and:

You can check out the previous week's Author Showcase to get an idea of what we are doing with these posts.

Cheers - Carl (@curie curator)

Wow. I'm very happy and appreciate it. Thanks.

Of course you can use my text and images.

You can also use my introduceyourself post. There I talked about "How am I and what I'm doing".

https://steemit.com/introduceyourself/@theguymasamato/who-is-this-guy-theguymasamato

Do you need more informations?

No that is great! Thanks :)

Hi Marco, the Author Showcase featuring this post is up :)

https://steemit.com/curation/@curie/curie-author-showcase-february-16th-2018

Thank you very very much!

Richtig saubere Arbeit, Respekt! Was für ein Programm benutzt du zum programmieren der CNC? Wo aus Bayern kommst du genau?:D

Servus, vielen Dank.

Oberbayern, Landkreis Altötting, in der Nähe der österreichischen Grenze. Du?

Das Projekt lief noch komplett über Easel. (Der Plattform von inventables).

Also von Fusion360 mit dem Easel Post Prozessor erzeugt und dann in Easel eingespielt.

Ich habe aber auch schon mit dem Universal G-Code Sender experimentiert. Klappt auch problemlos.

Das kenn ich noch garnicht, wir haben in der Berufschule hauptsächlich mit Vectorworks gearbeitet und dann mit der Software die von Format4 (Felder) bei der CNC mitgeliefert wurde. Ich komme ursprünglich aus dem Allgäu, studiere aber im Moment in Göttingen

Very cool. The animations are awesome

You can read about us here