ECCO - Silver maker or accumulator?

Introduction to the ECCO 'Free Energy' technology if you are not familiar

The grain

The first part of our investigation into the ECCO reactor was to look at the part processed fuel samples and the Nickel foil that is used to form electrodes inside the reactor.

A description of the novel foil production process can be found here.

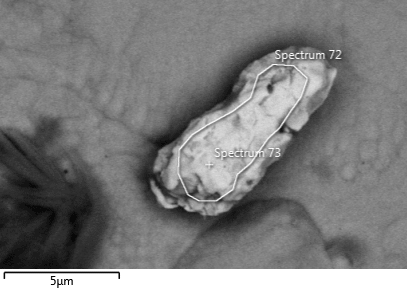

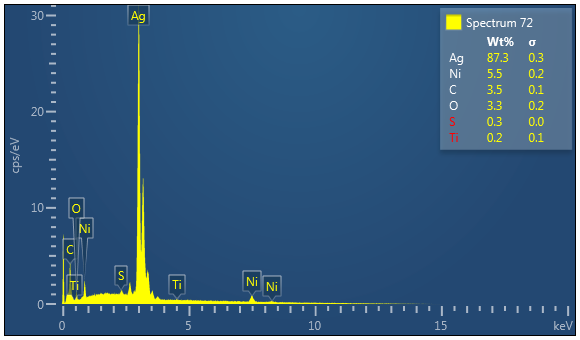

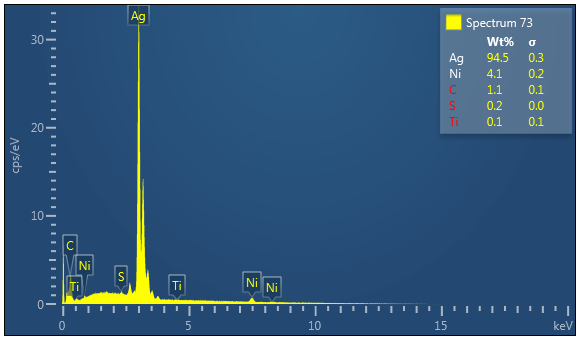

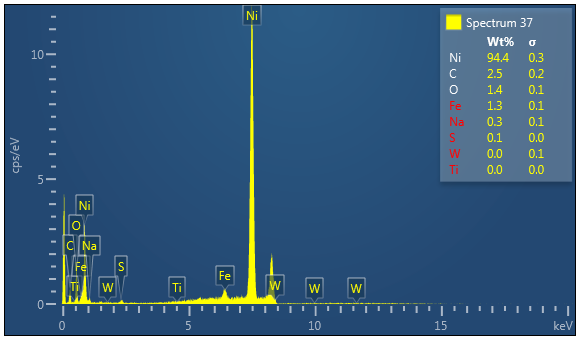

In the second set of SEM / EDX analysis conducted at Masaryk University, Brno, Czech Republic on 20th April 2017 - a 'grain' of something was found on a sample of ECCO 'Nickel foil'. It stood out because of the brightness of its back-scattering image, which is a good indication that it was of a different composition to the bulk of the Nickel and Sulphate on other parts of the sample.

microscope of feature on ECCO foil

What was it made of?

This 10 micron long, 4-5 micron rice puff looking object, revealed itself upon inspection, to be essentially pure silver.

Why is this interesting? Well, there is no silver whatsoever in the chemicals and apparatus used to make the foil.

The SEM/EDX machine operator said that the other detected elements were probably due to interference from the background that the grain was on, which is not unreasonable since they are mostly elements used in the foil making process. This is confirmed to a certain extent by taking a point sample which shows a higher level of Silver purity.

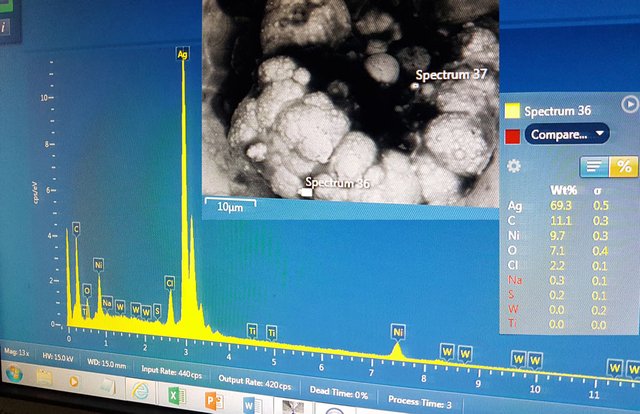

Confirmation of our previous finding

The reason that we went back to the foil for a second look, at a different sample, was to confirm if the detected copper and a range of precious metals were to be found in other areas. Below is an analysis from the 7th April 2017 session.

with embedded flake of silver on ECCO foil

Where did the silver come from?

Is this really silver being made in the foil making process, or did our silver meteorite crash land on the foil from planet precious? The first thought would be, could this all be contamination? If it is, then let us hope for a lot more!

The silver grain does not look like something that was formed in place. It looks too big to have been plausibly formed by transmutation. Transmutation normally occurs on a surface in small, low volume patches. It looks like a contaminant particle, that was moved in the electrochemical field and attached itself to the Ni foil being plated. Plating solutions can end up with "fines" in the bath and a cloth bag is commonly put around the anode to keep fines from the anode from entering the solution. It is probably a contaminant fine from the source of the electroplating solution or a fine from some previous electroplating operation.

It is an interesting hypothesis, one that needs to be discussed with Suhas since the purpose of the apparatus is not standard plating and the deposition process is very different from standard plating. This sample was singled out in this second session as it was not on a globular feature like the other precious metals and Copper, Zinc etc. that were seen in the first round of testing.

It will be interesting to see if we can get a sample silver feature tested with SIMS since in the case of Adamenko's work, the transmuted metals almost always did not have naturally occurring isotope ratios. If the isotope ratio is significantly off for ECCO foil silver features, then one might have a better argument to support it being made rather than accumulated.

Particle size is WAY too big for transmutation, 90+% conversion of something app. 6 e(-18) cm^3- at essentially the same time?

Probability is way down there near zero...

I'd also assume your plating solutions are industrial purity, which is only around the low-to-mid 90%. Some of the typical contaminants might prove to actually aid in reactivity, or supply some other benefit- or exactly the opposite, poisoning the surface or grain structure, etc. I should have called you on the "pure Ni foil" from the first, it's going to be high-purity, obviously, but not close to 99+ %, with this kind of process.

I think that the SIMS on the foil will be the big tell about what maybe going on.

With Adamenko, the isotopic ratios were not natural - in addition to the creation of non-periodic table elements.

Since it would appear that basically the same process is going on here in the foil producing process with similar output products (albeit we do not have the specifics from Adamenko for the combinations in this embodiment) - it could be that we see some strange data out of SIMS

With a unit in hand, each of the possible challenges can be addressed. We'd like to have that opportunity.