ECCO - An instant on/off ultrasonically fluidised dusty plasma New Fire reactor

It is with pleasure that we announce that the MFMP has been invited to openly test a claimed working New Fire reactor technology

No restrictions on our access.

When confirmed, claimant will make technology open.

This will make this the first fully described / open working New Fire technology in this epoch.

In brief

The "ECCO" reactor currently uses 8 alumina tube reactors driven independently to allow scaling of output power from around 1kW to over 8kW

- Current fuel: Ultrasonic processing of powders in light water for about 200 hours is then finished by pyrolysis

- 3 Ultrasonic transducers @ 19.46kHz & 1.5kW each for a total of 4.5kW

- Current fuel: Ti, TiH2, Ni, Al, LiOH, C, K2CO3

- Core reactor is standard extruded alumina cylinder

- Reactors in second steel sheath

- Starting status: Initial vacuum in cell

- Through fuel discharge provided by thoriated tungsten welding electrodes

- Fuel held in place by Nickel foil formed into a plug in to which the needle point of the electrodes passes

- Pure nickel foil made by plating from Nickel Sulphate onto steel using hydrogen plasma and ultrasonically de-laminating it

- Fuel not tightly packed, 22mm active zone in Al2O3 tube with 1.6g of fuel occupying <1/3 available space

- 1 MHz non-symmetrical waveform (fast rise, slow fall) pulsed DC discharge provided by MOSFETs through fuel

- 2000 - 2400V discharge potential set to prevent spark

- Approximately 100W applied in non-spark discharge

- Ultrasonic vibration at same 1MHz applied to fuelled zone in tube in order to fluidise the fuel components

- Between 15-30W used for the ultrasonic fluidisation

- Peak input power is approximately 1kW

- Core temperature (external of ceramic) 1100ºC using S-type thermocouple

- Tested for 3 months in accumulated on time, only 2-3% output variation during that time

- Heat exchanger enables transfer of heat to water which is heated to 101ºC

- Instantly stops reaction when turned off

- Water heated to boiling inside 5 mins of turn on

- Claimant used his, his partners and his teams expertise alongside publicly available discussions on the New Fire

- Reactor was arrived at by informed trial and error without specific theory consideration

- Many areas identified for improvement and now from a theoretical basis

- Good fuel testing platform

- Makes a lot of cups of tea

How it was discovered

Suhas introduces himself and describes how he came to look for the New Fire

Technical discussions on SoundCloud

Part one

Part two

Part three

Part four

Fuel Processing

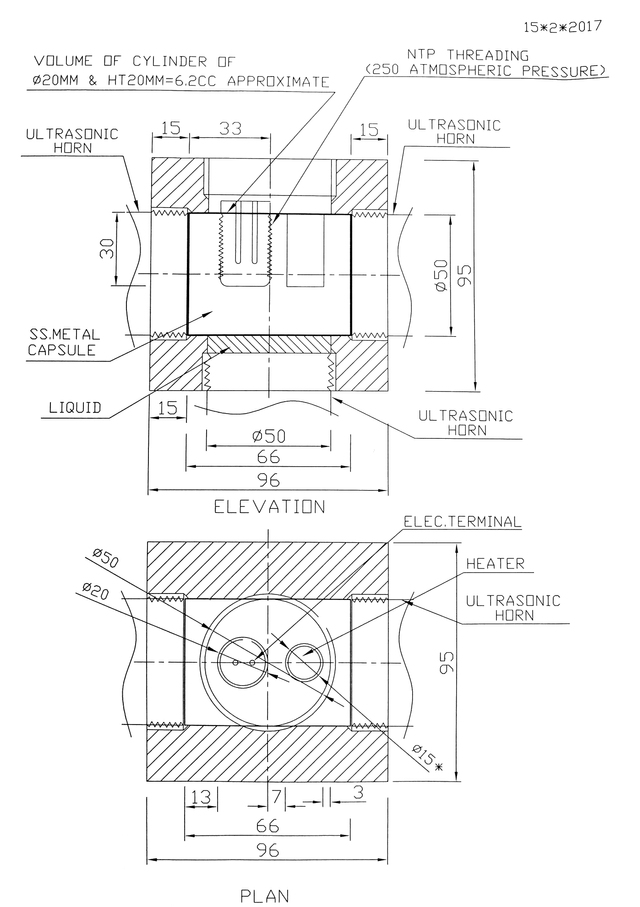

Fuel is processed in a chamber with the following design

3 resonant ultrasonic horns are attached to the above block with the following parameters: 19.4kHz & 1.5kW each for a total of 4.5kW. The X/Y arrangement of the high energy ultrasonics reduces the fuel components in a light water solution over 10s of hours from off the shelf powder sizes of 80-100um to 1-3um. At the same time the fuel components are cleaned. In addition, there will be cavitation resulting in potential charge cluster effects and nano bubble formation.

Overview of fuel processor

Uncapped fuel processor in operation

Fuel composition, processing time, reactor core form and fuelling

The reactor in operation

5 mins to get to operating temperature from 28ºC line water temperature

COP 8

Close-up on steam

Water droplets are apparently due to partial condensation in metal pipe exposed to 35ºC air - to be verified by lagging pipe

101ºC - Steam quality

Summary discussion

Next steps

We need to get a team and equipment to India as soon as possible to verify this technology and document it fully. MFMP team members have expressed that they could put time aside to do this, but it will take more than just time and shipping of equipment. We must be completely independent testers, with no strings attached and also ensure that the Indian is not compromised by those wanting to 'help'. This is a critical moment in the Martin Fleischmann Memorial Project's history. Your support has helped get us here - this may well be the home straight.

The work of all the citizen researchers out there have helped the Indian make this technology embodiment and you can see how frank he is about that in discussions. You can all pat yourself on the back for being a part of lighting the New Fire together.

What we need to do to ensure independent evaluation

- Raise money for duplicate production

- Raise money for testing team to participate in verification

- Ideally secure an SEM/EDX to do fuel / ash analysis without having to wait on or rely on the data from, third parties.

For those interested in an open working New Fire reactor becoming available, please consider a donation here:

MFMP Donation page

The project looses 4.5% on Paypal donations, so for those that can do a direct bank transfer, donations of any size can be made direct to Quantum Heat C.I.C.s (the organisation that runs the MFMP) bank account here, thus saving charges:

BANK: HSBC

Branch Address: 153 North Street Brighton, East Sussex, BN1 1SW

Account Name: Quantum Heat C.I.C

Sort Code: 40-14-03

Acc No.: 12631571

IBAN: GB48MIDL40140312631571

SWIFTBIC: MIDLGB22

Or bitcoin: 1JesTRUXU8jHb1haa1MoF2NvrU8gt5msCr

Alternatively there is a US 501.c3 that also supports the goals of the MFMP, you can request information on how to contribute by that route by writing an email to [email protected]

This is a huge, generous breakthrough by Dr. Suhas.

Please pass on our congratulations from California from someone who has work on facilitating "Cold Fusion" development for 28 years.

For sure we will. If you have any questions you would like him to address, we will have another technical interview with him tomorrow. Please post them here.

It is so wonderful that a practical technology may come from India since they need this so much.

On your end, if validation of this system is your short term goal, I would request Dr. Suhas to follow the criteria that SRI has established for "LENR" validation (I paraphrase):

On demand on/off control.

Consistent results from identical, separate and complete systems.

Moveable system, can be tested in different, independent labs.

System components manufactured to the identical written specifications.

Dr. Suhas has the burden of validating his calorimetry. As you may have noticed lately, this can be a serious bone of contention. The expert in this area is Dr. Fran Tanzella at SRI. No doubt Dr. Tanzella has a colleague in India that is equally as competent as he is in validating calorimetry measurement setup and data collection. Finding this expert is a good place to start your validation efforts.

I would ask Dr. Suhas to verify that the materials and components he uses are not only well-documented, but also commercially available (I believe that this looks to be the case from what I have seen in the videos). Dr. James A. Patterson got bitten by this problem by having only a single European supplier for the porous nickel coating he used in his Patterson Power Cell. When the supplier when out-of-business, the nickel power could not be reproduced. Be careful to get full materials disclosure for replication purposes. And best of luck.

Ultrasonic 1MHz are you sure? or did I misread?

19.4Khz for processing fuels

1MHz phonon sound and 1MHz asymmetric 2000-2400V pulse for non-spark discharge in active reactor

8MHz is normally used in the gynaecological field

Isn't this all extremely complex?

Not really, there are two components - one, fuel preparation... on the face of it, it is about getting the particles from 80-100um to 2-3um - however there will be cleaning. Also, since there is cavitation, there may be heavy electrons formed and also potentially hydrogen species ad/absorbed into the processed powders.

Maybe MFMP will show a drawing of the reactor?

Will look to do this

Is there a procedure to prepare the fuel?

Detailed essentially in the sound cloud interview and videos above.

How exactly the reactor is started and stopped?

The 1MHz frequency generator is switched on or off and applied via MOSFET driver to 1-8 cores depending on desired power output.

Are any further initial steps needed to start?

As said above, a vacuum is initially applied.

Does the reactor gets an input of ~1KW and the output is ~1KW and with the frequency it is ~1.015 KW and ~8KW out?

The input is in 1-8 quanta of 115-135W and the output is around 8 times that.

The Indian said in the technical interview, that he has not tried to turn off the 1MHz plasma / ultrasonics individually, but will try.

Ultrasonics easily make mist. Is it mist or steam?

It was steam for sure. very high exit velocity also, the misters just seem to drift.

There seems to be both hydrogen and oxygen inside the fuel load

Yes - but the Al was added to getter water (and hence O2) out of play.

Because the reaction starts up instantly, this implies that the LENR active nanoparticles have already been formed in the fuel preparation process...that being 200 hours of cavitation in light water.

There was only 2-3% fluctuation over 3 months. Not likely persistent for that period. The cavitation in light water may be important though - a test with similar sized particles produced differently would clear this up.

Does the fuel get wet? Have chemical reactions been ruled out?

Fuel is dry, 1.6g in each 22mm long small diameter core of 8. Tested for 90 days with approx. 8X gain.

Hi Bob;

I’m trying to get my head around the hardware pieces but I’m clearly missing something. I think I have a bit of understanding of the “fuel processor”. but I have some confusion about what goes on top of the “processor”. Is it a cap of some sort? Another transducer and tube? He talked about water flow at some point when pointing at the holes around the opening where the fuel slug and heater slug go.

The drawing you posted doesn’t really match the stainless cube at the focus of the transducers, so I haven’t fired up my milling machine yet… ;-)

Does this “processor” assembly have anything to do with the reactor portion? You talk about the water supply as being ambient temp and pressure but I haven’t seen any coolant piping except where the steam exits. I wish you had followed that steam line to the reactor. In fact from the “water tap” to the steam exit.

It can be either a cap or another ultrasonic horn... this would allow 6kW input power - but this was not used.

The holes are for water cooling.

The drawing is for an updated version. The date you can see on it is very recent.

As I understand it, this is only the fuel processor.

A relationship needed to be built before the unmasking. Suhas is on board now.

Depending on testing teams times and funding, we may test the ECCO before testing me356 reactor.

The reaction chamber is dry and starts in a vacuum, there is no cavitation in the working reactor. There is cavitation in the fuel processing phase.