ECCO - New fire individual reactor core cross-section and operation

Introduction to the ECCO 'Free Energy' technology if you are not familiar

Single reactor core construction

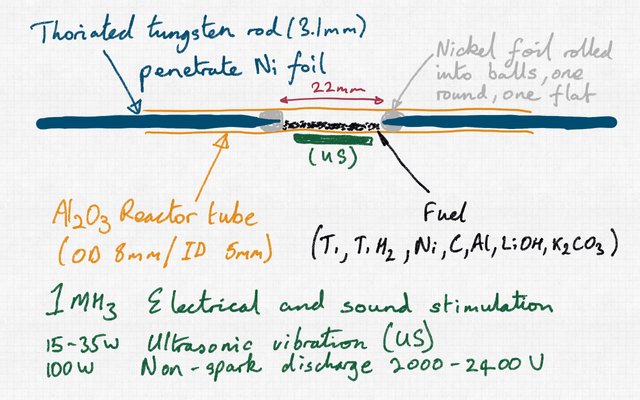

The individual core construction of the ECCO reactor is simplified because the fuel is pushed into place via scrunched up balls of specially prepared Nickel foil. The Nickel balls, one of which is flattened, form the two breathing sides of the 22mm long, 5mm inner diameter volume of the reaction zone, which is only part filed by the 1.6g of fuel. The free space allows for the 1Mhz, 15-35 watt of ultrasonics to fluidise the fuel elements that are all under 5um and ideally between 1 and 3um to enable resonance.

The fuel is comprised as shown in the figure 1 below.

Figure 1: single core construction

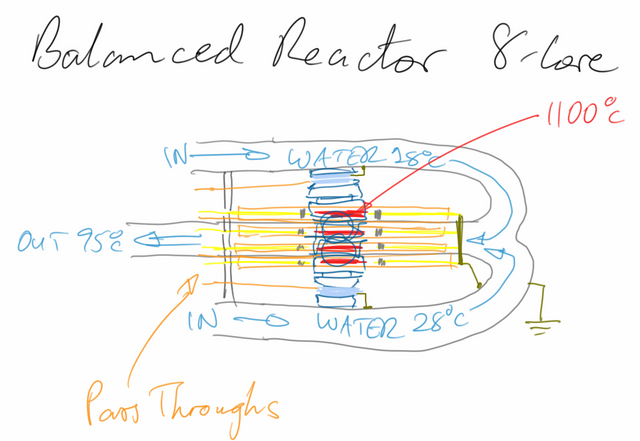

In addition, it is understood that there is no particular sealing of the individual tubes as the 8 cores are in a larger sealed chamber that has electrical feedthroughs for non-spark discharge and ultrasonic stimulation. This greatly simplifies construction.

The tapered ends of the standard 3.1mm thoriated tungsten welding rods penetrate into the Nickel foil making an effective conductive contact.

Figure 2: Inserting the core electrodes

Operation

- Before the reactor cores are started for the first time, the chamber in which they reside is pumped down with a vacuum.

- At initial turn on, the ultrasonics loft the fuel and the 2000-2400 volt, non-spark discharges, rapidly warm it.

- It is understood that the TiH2 then releases its H2 and this leaks out into the wider vacuum chamber housing all the cores, thus creating a large low pressure H2 reservoir enabling long term operation and providing the most thermally conductive gas to couple the heat generation of the reaction inside the alumina tubes with the thermal extraction surfaces.

- The reaction produces heat until the 1Mhz discharges and ultrasonic stimulation are turned off.

Figure 3: Cross section of ECCO reactor with pass throughs from sealed chamber holding individual cores

The frequency of the ultrasonics is automatically adjusted slightly as the reactor warms to maintain resonance.

Update based on 5th Technical discussion

Wondering about the ECCO reactor, a single core input power is 130 w? 8 core total input power is 1 kw ? (100 w 1 MHZ pulse discharge of 1000-2400v + 30 w 1 MHZ ultrasonic), Don't need the resistance wire heating reactor?