April Showcase - Brew Day | American Amber Ale

This is my contribution to the Showcase April Initiative the purpose of which is to share your best posts on Steem.

Last week, I decided to brew an Amber Ale, because I love this style of beer. I haven't brewed in almost 6 months now, so I felt a bit rusty. My brew method is BIAB (brew in a bag), it means that you put the malts in a bag when you're mashing.

I'm not going to go into every detail about brewing, but if you know even something about beer, then you might understand what I'm doing and explaining.

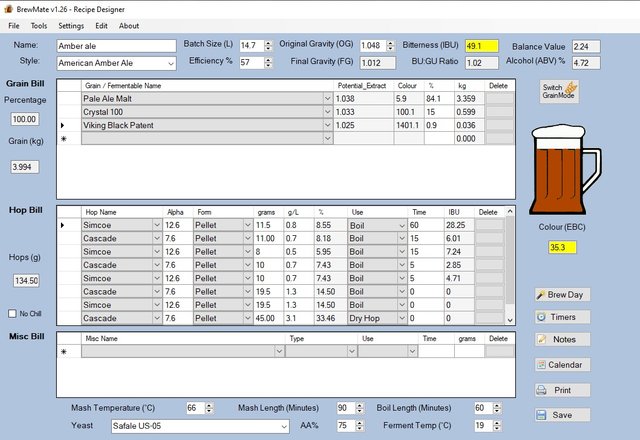

I use the software Brewmate (it's for free) to create my recipe for the beer. Here is my amber ale recipe.

The malts for this brew: Viking Pale Ale Malt, Viking Crystal Malt 100 and Viking Black Patent Malt.

Firstly, I started heating up about 10 liters of water to a desired temperature of ~ 71° Celsius.

Meanwhile when I'm waiting for the right temp, I weigh the malts and put them into the bag.

When the temperature is right, put the bag with malts into the pot. Make sure all the malt is wet and try to dissolve the clumps. After you've done this, the temp should be around 66° Celsius.

Then I put a sleeping bag around the pot, to keep a steady temperature. I leave it like this for about 90 minutes. This is called mashing and the goal is to get the sugar extracted from the malts.

To get even more sugars out of the malts, you can sparge. It means that you pour hot water (~90° Celsius) on the malt bag and let the water run through the malt and into the pot.

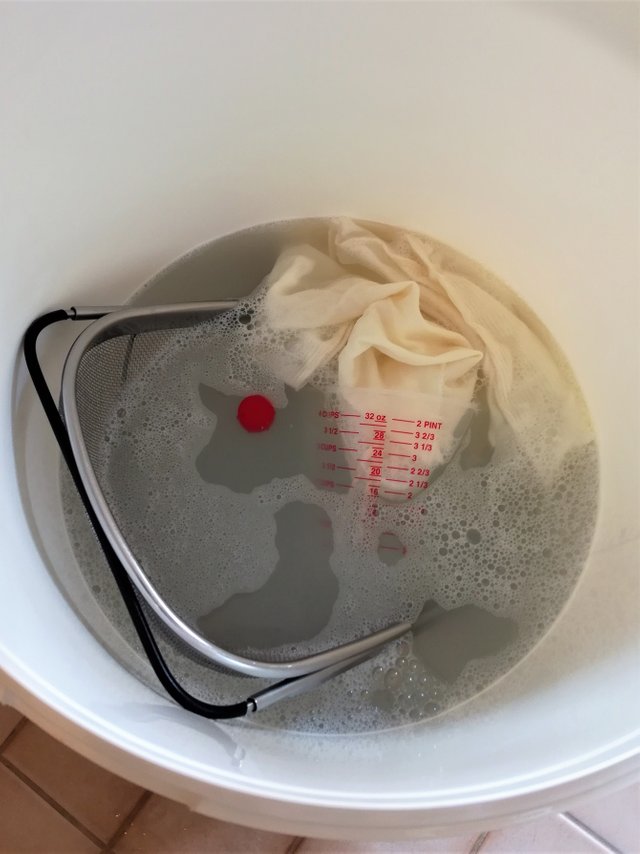

After this, you heat up the wort (the liquid extracted from the mashing process) to the boiling point and add the first addition of hops @ 60 min. If you want, you can first remove the foam with a strainer to get a clearer end product. The foam is caused by proteins in the wort that coagulate due to the rolling action of the boil.

Set the timer on 60 minutes countdown. Next hop additions will be @ 15 min, @ 5 min and @ flameout (0 minutes).

The hops I use! Simcoe @ 60 min, Simcoe and Cascade @ 15 min, Simcoe and Cascade @ 5 min, Simcoe and Cascade @ flameout (0 min) and then I'm also gonna dry hop with Cascade.

When the boiling is done (60 min), the next step is to cool down the wort as fast as possible. I use this technique: fermenter bucket, ice packs, cold water with an ongoing flow. It takes about 40 min to cool it down to yeast pitching temperatures (18-20° Celsius).

Now comes the most important part! Remember! Everything that touches the cooled wort should be clean and sanitized! I use Star San for that (Star San is an acid-based no-rinse sanitizer that is effective and easy to use). Otherwise, your beer will be ruined.

It's time to filter out the hop gunk. This technique also automatically aerates the wort when the wort drops down into the fermenter bucket. The yeast needs oxygen to reproduce.

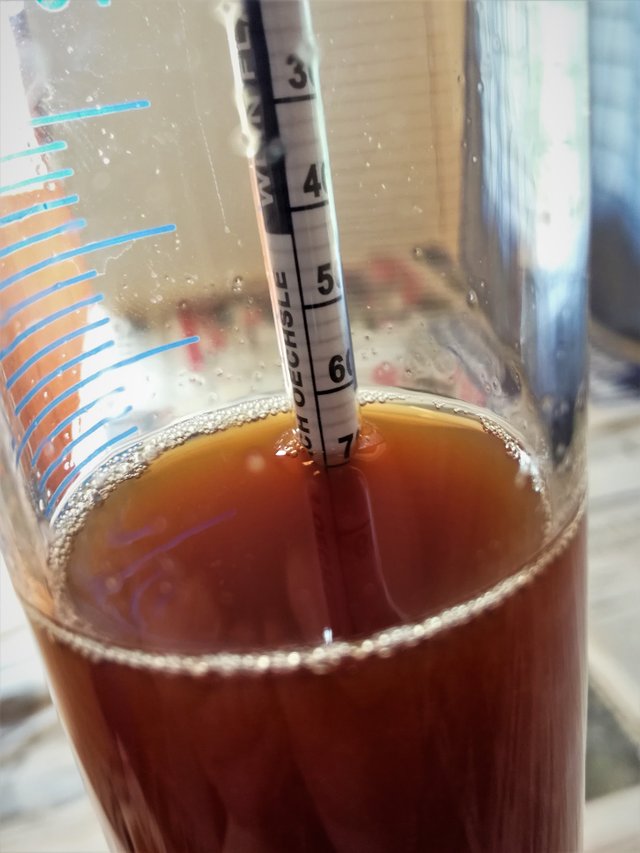

Checking the original gravity with a hydrometer. Original gravity measures how much sugar is present in the wort (density) before it is fermented. The OG will provide the brewer with a good idea of the potential alcohol percentage for that particular beer. My OG reading was at 1.069 and my aim is 1.048, so I added boiled water to the fermenter bucket to get the right OG and amount of wort (about 15 liters).

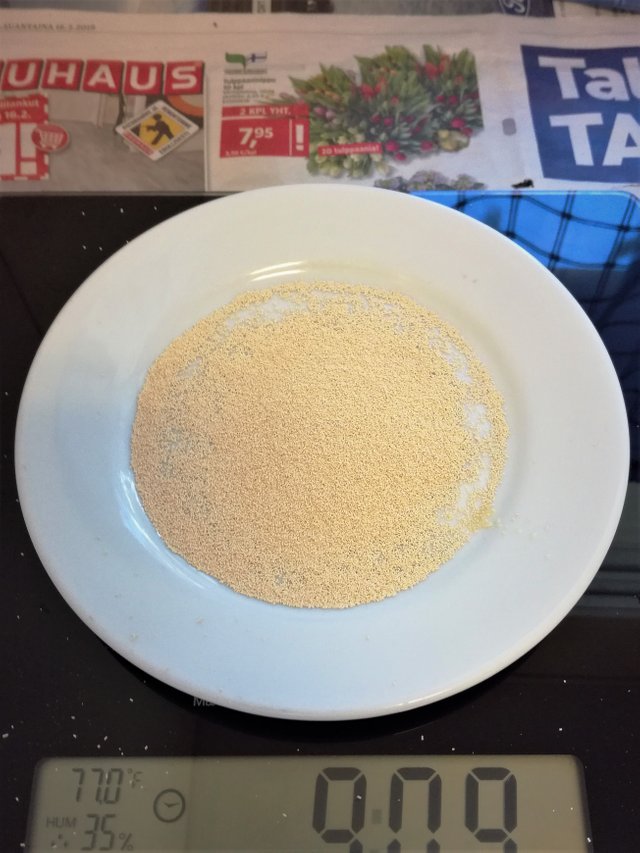

It's time to add the right amount of yeast. For this beer, I use a dry yeast called Safale US-05. Remember, the wort has to be in yeast pitching temperatures before you add it (18-24° Celsius).

Lastly but not least, put the fermenting bucket in a space with the right temp for your specific beer. The fermentation should start within a day, the sooner the better. Try to keep the temp steady so that the yeast stays happy! I leave it like this for about 2 weeks until it's time for bottling. On the tenth day of fermentation, I'll dry hop to get more nice aromas. Now comes the most difficult part, the waiting time!

Check out my latest beer reviews:

Borran's Beer Review: Must Kuld

Borran's Beer Review: Almost 5 Year Old Orval!

Borran's Beer Review: Lervig Hoppy Joe

Borran's Beer Review: Omnipollo Nebuchadnezzar

I hope you enjoyed my post! Thanks for stopping by!

Borran's Beer Review: Must Kuld

Borran's Beer Review: Almost 5 Year Old Orval!

Borran's Beer Review: Lervig Hoppy Joe

Borran's Beer Review: Omnipollo Nebuchadnezzar

I hope you enjoyed my post! Thanks for stopping by!