The Cutting Tools: A Proof Iron Sharpens Iron

Or why certain fluids could make an environment a conducive place and others certainly will not (refrigeration and air conditioning). These questions are not what I would like to answer today but there is this one that has always had me wondering as the book in a Bible says iron sharpens iron.

Well, every metal in this country by the layman is referred to as iron, if you are from this side of the world you should know this. But why would iron sharpen iron? It’s a question I have always asked myself. Perhaps, I made sense out of nonsense when I saw my mum pick up two knives and slide it against one another. When I ask why She said she was sharpening the knife I was probably just dumb enough to ask which one of the two she was sharpening or was it both?

I took the explanation as a good one and held the belief that iron sharpens iron so whenever I got to the suya stand with the northerners doing their knives this way compared to how fast their knives cut the dried meat. I was always happy with that explanation from my mum, till I gained admission into the university when my knife got blunt and I tried severally with the method of the northern suya sellers and my mum but my knife wouldn’t just become sharpened, I gave up and got another instead.

Not until recently when I came across the lathe machine I got to see a proof of what the holy book was saying. And why would a stationary metal position just peel off or remove the metal of another material?

Let us look at how the lathe machine operates

If you have ever seen a lathe machine operate then you should understand what I have been driving at and where I am heading towards. But do not get me wrong please the lathe machine does not only deal with metals but wood and even plastics can be machined on a lathe.

The basic operation of the lathe

wood and nail experiment: image taken by me @adetola

Let us do this little experiment

Get a nail and a wood, pick up this wood a plywood and place it on a fixed surface (i.e. where it can’t move) then repeatedly make a straight line with the nail on the wood. What do u notice?

The nail makes a mark in the wood by peeling off some part of the wood this happens at the first stroke. What if you now on that same line move in a to and fro movement in this straight line you made earlier?

You begin to notice that the straight line that was made with the first stroke gradually begins to grow deeper into the wood and if continued this might lead to the wood breaking into two separate parts at the line of action.

But firstly I have some questions to ask

Why did the nail could cut the plywood?

How did it cut it?

wood and nail experiment: image taken by me @adetola

The answer you would probably give is that the wood is softer than metal and the nail has a pointed edge which allows it to burrow inside the wood at repeated times thereby cutting the wood gradually.

Very good!

If you thought like that then you might as well have understood how the lathe machine operation works.

For the lathe machine to work it has its workpiece which is the wood positioned in the middle of a rotating component in the lathe called the spindle. It is the spindle that rotates the workpiece which is any metal, plastic or wood being machined or reshaped. The spindle only moves in a rotational motion and it is fixed to the headstock.

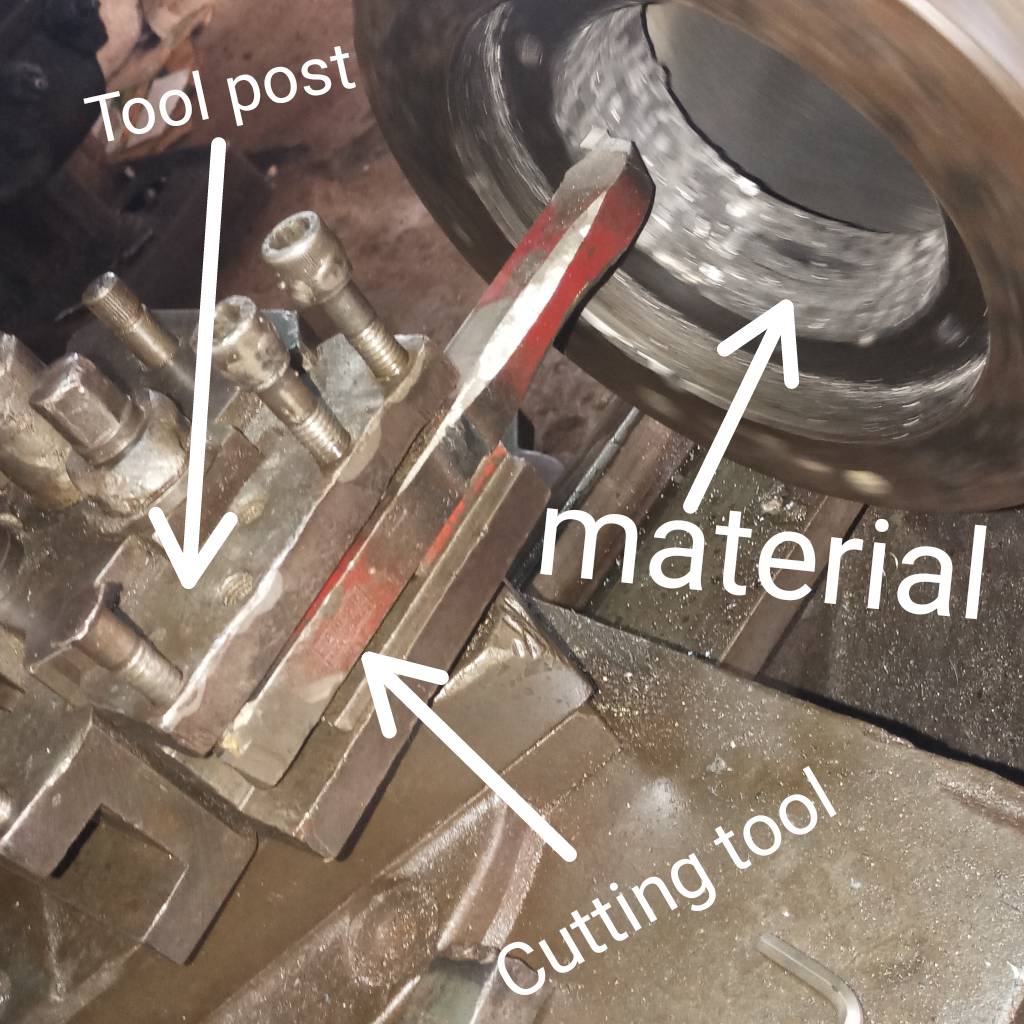

But for the operation to be carried out on the lathe machine which could be turning or facing just as explained earlier parts of the workpiece (either wood, plastic, metal) must be removed and this is not done by using nails but rather a tool called the cutting tool. The cutting tool is placed inside the tool post which either moves forward or backward in a manual or automatic way depending on what you set on your control.

tool post: image taken by me @adetola

As the tool post with the cutting tool pointed out meets the rotating workpiece, friction occurs at a high temperature making the workpiece material to become a little soft than it would be at high temperature. It is this friction that makes the cutting tool to tear out or penetrate the workpiece thereby making the workpiece material shear and flow plastically on the surface of the tool.

The flowing out of this metal from the workpiece forms what is known as chips (I hope you are not thinking of French fries or any kind of chips right now). Well this kind of chips are not edible it is simply the metal, wood, and or plastic shelled off your workpiece.

Note: the tool should only touch the material slightly and not too deep. Too deep might cause the machine tool to break.

Now, why do you think the cutting tool was able to remove metals or reshape the metallic workpiece?

The truth is even though they both look like metals, they are not made of the same material as one has some metallic properties which make it stronger, harder and different than the workpiece. Also, the shape of the tool used in the tool post is not the same. This gives rise to different types of cutting tools with different shapes used for carrying out different lathe machine operations.

I will leave a short video to show all I have been explaining above, I would like you to watch carefully

Let us have a look at the cutting tools.

cutting tools: image taken by me @adetola

Cutting tools are like the backbone or the instrument used in shaping out how you want your tool to the shape and size you want. It is the one that reduces the size and withstands the friction between the contact of the Cutting tool and the workpiece. The Cutting tools are strong and corrosion resistant metals which are used in reshaping of different types of metal. From the types of metals or materials used as a cutting tool from ceramics to diamond, they have some embedded properties which cannot be seen but noticed these are.

Hardness

As a man, you would say you are Hard maybe due to your physical presence of abs and muscles, but hardness goes beyond that. One can be hard when everywhere is calm and everyone would think oh! He is a hard guy. But what really happens in a bar fight does the muscle man wait to defend himself or runs away. F he waits then we can say he is hard to an extent but if he runs then he is not hard enough for the task. This same guy that waited for the battle fight might get into a gunfight and disappear before the first gunshot, if he doesn’t we can say he is hard to another level but if he runs then he is not hard up to that level. The same goes on and on.

We actually talked about this from the nail experiment we performed earlier about the nail being harder than the wood. But hardness goes beyond physical appearance or dropping it and not breaking it is a matter of the metal being able to withstand breaking or deforming when it is hot, this terminology in engineering is called hot hardness. This is like the next form of hardness just like the guy in the bar fight and gunfight, these metals must be able to do their jobs at high temperatures as well as at room temperature. This feature or property determines a good material for a cutting tool. But not only hot hardness let’s move to the next

Toughness

cutting tool: image taken by me @adetola

The man in the example above we can say such man isn’t hard, but hardness is different from being tough. Let us assume or say he really got into the bar fight and he gets hit but withstands the pain to hit back the opponent. Just like in the moves the opponent feels the weight behind his punch and runs away as soon as he gets up. Yeah! we all shout at the cinema and we laugh just because he runs away like a dog with its tail between his legs. There is something here, he gets courageous to pick up a fight because he is a hard man, but he can’t withstand a hit after he threw the first punch.

Such opponent is said to be hard but because he failed after receiving a hit from the muscular guy (you) and runs away he is not tough. But you, on the other hand, being courageous to wait and not run from his threats and even withstand his bunch you are hard and tough. Therefore, it is easy to see that a material can be hard not be tough likewise it could be the other way around. (please do not get into a bar or gunfight as these are just used as explanations. It is not a test for hardness or toughness of man).

A material is said to be tough when it engages the workpiece and does not fail in action. The lack of toughness in a material could lead to serious machining headaches when you are working as the material (i.e. cutting tool) would always break or fracture in an operation. Trust me you don’t want to experience this when machining.winks

Wear resistance

Watching game of thrones is what most people did worldwide, and we can’t just get enough of it as the episodes keep winding down and down. This is because the game of Thrones is very much interesting and the attention of people viewing it that it has got. In fact, most game of thrones viewers always says the season is too short and deserves to be more episodes longer.

This can be likened to your cutting tool and the job it does, as interesting as the game of thrones is to viewers so is the cutting tool to the machinist. A machinist best enjoys his job when he doesn’t have to grind his tool several times before he finishes just one turning operation. It can be compared to having to wait for another exciting episode f game of thrones.

A cutting tool should be able to withstand wear and not just fall off in dust although they wear gradually but very slow and could last you for a very long time.

Corrosion resistant

Many already know what corrosion does and what a menace it is to the world, you may know that for corrosion to occur you only need two elements which are always present during machining. In fact, the tool must be cooled by application of a fluid called the coolant and of course air is almost everywhere except in a vacuum which machinists cannot operate. Therefore, the cutting tool should be resistant to all forms of corrosion.

These are the basic implant features found in the materials of the cutting tool, but I am yet to discuss the materials that have this features in them. These implanted elements that make them special is not what I would be discussing today but I won't leave here without listing the materials used to make the cutting tools. They include;

- Cemented tungsten carbide tools

- Coated carbide tools

- Ceramic and cermet tools

- Diamond, CBN, and whisker reinforced tools

These are basically the material classification of the cutting tools we have, I would be discussing each briefly in my next post alongside how the tools themselves are shaped and used on works.

Conclusion

The cutting tools which are fitted inside the moving tool post are like the vital parts of the lathe, they are responsible for reshaping and resizing of any material used on the lathe. Cutting tools withstand friction as well as wear to ensure the best form of work is achieved in machining.

Cutting tools determine the kinds of operation that is done on a material and with special imbibed in them like hot hardness, toughness, wear resistance and corrosion resistance. These features or properties are what distinguishes the cutting tools from the material being machined.

Materials used for making the cutting tools and how they are shaped themselves to carry out their operation on the lathe are wonderful and quite easy to the eyes wouldn't you mind seeing for yourself?

Thank you for reading.

References

Here are the books used to gain knowledge about the machine tools and the links.

- Cutting tool applications by George Schneider, Jr. Cmfge

- Geometry of single-point turning tools and drills, Fundamentals and practical applications by Astakhov, V.P

- machine tools

- Manufacturing Process II

- what are machine tools

- wiki - Machine tool

all images and videos in this post were taken and created by my infinix zero five.

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

Cutting tools form the basis of the machining industry

Yeah.. They are like the knives used for cutting your bread.

Awesome post!! Keep it up and check out THIS POST as well as I have something similar.

To listen to the audio version of this article click on the play image.

Brought to you by @tts. If you find it useful please consider upvote this reply.

Thank you

The lathe is one versatile machine tool we have in production of parts. In the hands of a highly skilled operator, one can derive a wide range of parts to satisfy one's requirements.

Although, most times it has to be complemented by a milling machine.

Yeah.. True but not all times do you need the milling machine. There was this part we fixed some days ago. It didn't even get near the milling machine.

Please let me know if you ever come across a lathe which does spit out potato chips!

😂😂😂... I will definitely share that once i see something like that.

These cutting tools are the backbone of machining and they really do posses the properties needed.

Truly a case of iron

sharpeningcutting ironYeah.. You got the point. Thanks for reading.

One of the sights I cherish most in Engineering is a skilled Lathe operator going about his job as if he's drinking water. They make that tedious task look so simple.

I have seen firsthand how hard those cutting tools can be. Great explanation you gave here. Always a pleasure to read here.

This is another part of mech engineering I love so much......

Manufacture technology.... There is more to this when u start talking about the feed rate and all that... Do you know as much as the cutting tool is hard it losses its cutting sharpness and requires sharpening....

Any time I hear lathe I think of of things like turning, shaping, etc.... I mean the operation carried out on it

I have a question

can lathe machine use a cutting tool of more than one cutting edge?

Yeah... Its quite complicated, i might get there soon i hope my readers enjoy it.

You are right sir, i am coming to that. Stay with me.

That will depend on the materials you have it is allowed in my workshop but the other edge would be stuck in the tool post. But only one cutting edge can be used at a time for an operation.

Quite nice how you presented this. I love the video part, brought back memories of my days with those lathe machine!

The tools are very important part of machining..The Hardness and toughness are the important properties that makes it what it is...

Nice compilation

Thank you sir.. I am happy to have brought back good memories.

You sure did!!!