Project: My Own X-Carve Dust Control System - Concept

Habedere everyone,

welcome to my first project here on Steemit.

Prolog

For a long time (many years) I’m dreaming of my own CNC machine.

Last November, after a long period of saving money and selling unused stuff, the dream come true.

I ordered the "1000mm Inventables X-Carve" from the european distributor RoboSavvy.

https://www.inventables.com/technologies/x-carve

https://robosavvy.com/store/cnc/machines

The machine is nearly perfect for my DIY projects. I regret not a single Cent.

Of course you can not compare it to a professional CNC. That’s far way.

But for me it fits perfect.

If you need more Infos or my detailed opinion just leave a comment below.

What I also knew from the beginning, the X-Carve itself it's a project.

There is enough room to work and improve the machine.

And so my first project is one of these improvements.

X-Carve Dust Collection

Of course there is one to order. But that is not a option for me.

https://www.inventables.com/technologies/x-carve-dust-control-system

I want to create my own.

In general that is nothing completely new.

There are a lot of threads and videos where people show their ideas.

And also mine will have some similarities to the existing ones.

Let’s start!

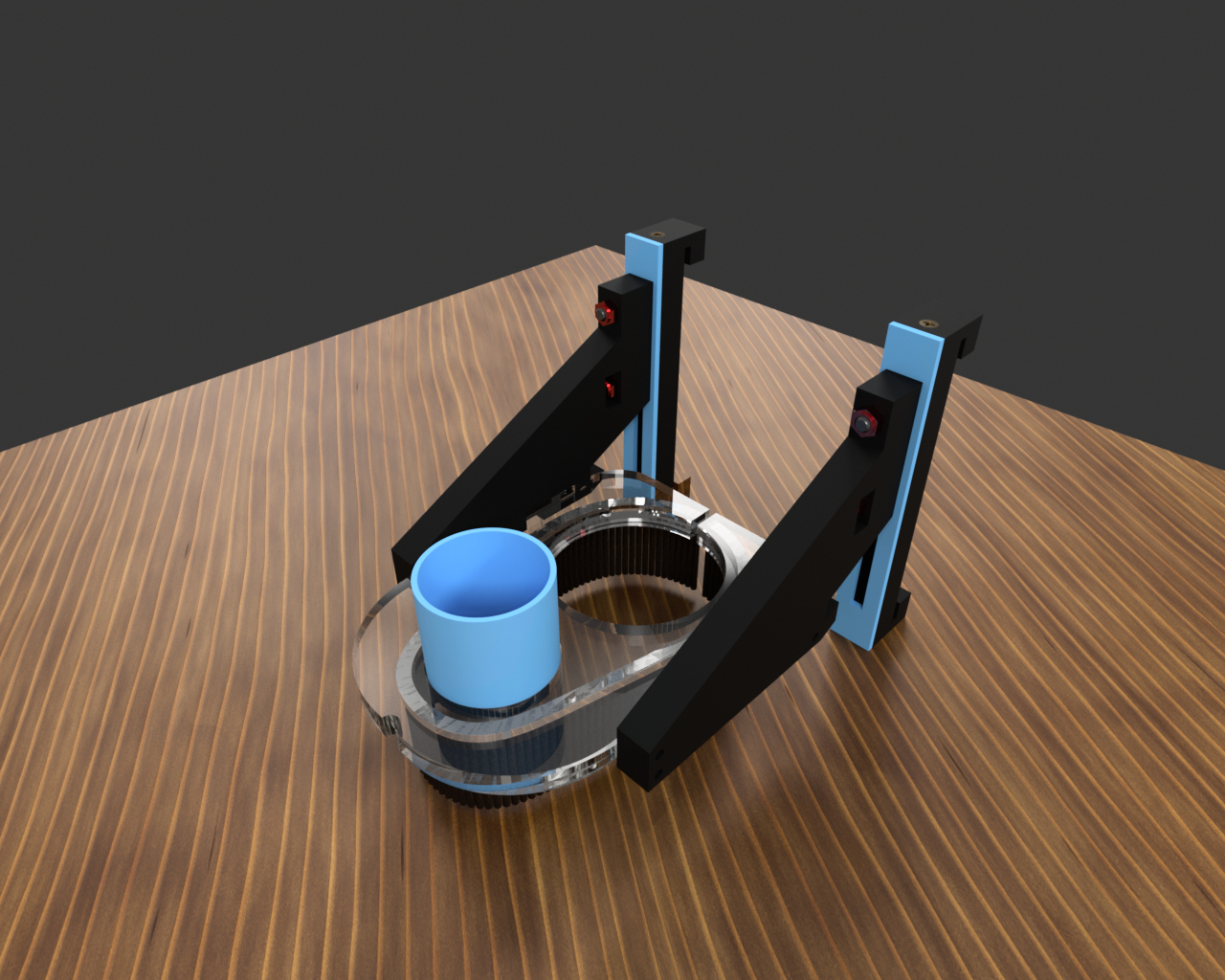

One of my first steps are some concepts on the pc.

My favorite "all-in-one-tool" is Autodesk Fusion 360.

Modeling, Rendering, Animation and even CAM.

After a few days/weeks I finished my concept.

Here are my some rendes of the complete project.

What's next?

I will show you some photos and infos from the work in the shop.

Servus and cu next time.

2nd update.

https://steemit.com/woodworking/@theguymasamato/project-my-own-x-carve-dust-control-system-main-parts

I have wanted to get in to cnc for a while now. I think a smaller machine like the one you have is the way to go. I will look forward to your posts on it. Thanks.

There is also a 500mm and 750mm model available.

Retroactively considered the 1000mm machine was maybe not the right choice.

You need a lot of space in your shop. My "table" has 1200mmx1200mm.

How do you like the X carve? I like the other gent am interested in CNC but am a little apprehensive on the price of a good mill.

I like the X-carve very much.

The contact with inventables and robosavvy was very helpful, fast and friendly.

Also the shipping from the states to germany worked quite good and eveything was in a perfect shape.

The X-Carve is a kit, witch means you have to build the machine from a lot of small parts.

But that was not a problem at all. The online video manuel explains everything.

All parts are well made and fits perfect together.

Till now i cut differnt types of wood and pmma.

I'm very happy with the results.

2 issues that i found for the moment.

(Only a european problem)

-The bits and collet are in inch and dewalt exclusive.

-The minimum rpm of the dewalt is to high for some kind of materials.

So If i knew this from the beginng i wouldn't buy the Dewalt.

I would use a german spindle.

http://www.kress-fraesmotoren.com/en/kress-milling-motors.html

If you need more info, just leave a comment.

Awesome. Perhaps adding a rheostat/router speed control to the power input of the Dewalt would help you slow the spindle down. They sell them here in the states at a cheap tool shop called harbor freight.

Anyway followed you to keep up with your further projects.

Thanks