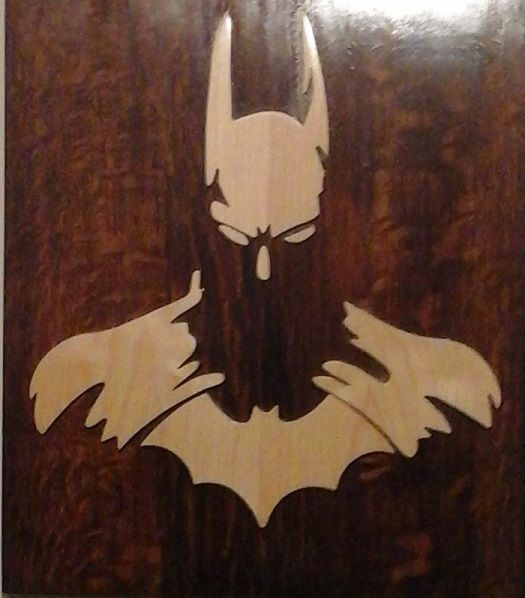

Past Commissions : # 1 Batman Plaque.

Over the years I have made many different pieces and had a variety of commissions.

Even though there are no photos of the process I normally take a picture of the end piece.

In my pre steemit days this was to show prospective clients what I could do and it has also been good to spark off design ideas .

Therefore I thought it would be useful to post the photos and describe the pieces and how I made them.

This first post is a Batman Plaque I was asked to make.

I was at a Christmas fair exhibiting my furniture and a couple walked up and we had a conversation.

After looking through my photo albums they inquired if I could make a birthday present for their son.

They showed me a picture which was literally a printed silhouette but said they wanted it in wood.

My first suggestion was to make it from veneer but as the discussion progressed we decided upon a solid dark background with a lighter raised foreground.

We agreed a price and they gave me a deposit.

Making the plaque.

I chose 3/4" quarter sawn oak for the background ,because of stability , and stained it dark with van dyke crystals.

For the foreground I used 1/4" sycamore .

The background was straight forward enough to make.

I found some heavy figured oak at the timber yard and planed it all round. I then biscuited it and glued it together in two pieces.

It was then cut to size, sanded to 240 grit and stained.

I then gave it two coats of fiddes clear glaze to seal in the stain.

The sycamore was a 1" piece which I deep ripped so that I could book match the foreground.

Book matching is technique where you split a piece of wood and open it like a book to give a mirror image effect.

I then glued the two book matched pieces together with just glue.

I had enlarged the original picture and traced it on to the sycamore making sure I was using the best grain.

Then I simply cut it out on the scroll saw and sanded the edges.

Now I needed to lightly trace on to the background where the sycamore cut outs would go.

I then scraped away the glaze and stain in these areas so that the glue would stick.

I also scratched the surface to give the glue a key.

Then I carefully glued each piece in place making sure no glue squeezed out along the edges.

This required some interesting clamping but I got there in the end.

A final sand and three thin coats of clear glaze later and the plaque was ready.

The client was happy and later let me know that the birthday present was well received.

It was an interesting piece to make and surprisingly more difficult than I first realised.

There was no real room for error as it was purely a visual piece.

If you have any questions about woodwork, furniture or being self employed as a craftsperson let me know.

I know my wood and I have spent years teaching myself furniture making , furniture history as well as living it as a self employed cabinet maker .

I am also in the process of writing a

'How to series: Setting up a Woodworking Business'

Which you can read here;

Part 1: Workshop

Part 2: Tools and machinery

Part 3: Finding a good timber yard

Part 4: Deciding what type of woodwork you are going to do.

Still I am learning every day and the journey is the point.

Many thanks for reading,

Until next time,

@jist