Stirling Engines - Exploiting Temperature Differential to Produce Mechanical Work

Engines and Railways

When the word engine is mentioned, the first thing that pops into most people's mind is the motor vehicle engine. However different engines have been in use since the Industrial Revolution. In the 1930s and 1940s, my grandfather worked in the Nigerian Railway Service. The trains in use those days were coal-powered steam engines, which were dirty and required transportation of bulky coal in the train. Of course, since those days we have improved in the technology of our engines, and we now have more efficient gasoline combustion engines.

To understand how any of these types of engines work, we must explore the physical concepts which make them possible. Engines take advantage of the difference between high and low temperatures. This post is about steam engines, the challenges that are inherent in them and a little-known type of engine called the Stirling Engine. Stirling engines are much like the steam engine except that it corrects most of the issues of steam engines and uses no steam! While it is not very popular, Stirling engines were developed around 1816. Without further ado, let us examine how engines work.

Engines

In a post I made two weeks ago, I discussed the concept of fuel cells and how they may be a viable alternative to combustion engines in the future. Engines are sometimes called motors. They are machines that are designed to convert one form of energy to mechanical energy. Scientists sometimes classify engines based on the material that drive them. Heat engines are ones that burn fuel to generate heat which is used to do mechanical work. Electric motors take electricity as inputs and generate mechanical work. Vehicles are driven by heat engines otherwise called Combustion Engines because they burn fuel (usually hydrocarbons, like petrol and diesel) to release heat which is used to produce mechanical work in the form of motion. Heat engines have combustion chambers where the fuel is burned to produce heat, making the gas to expand and push a piston and drive a machine.

There are two basic types of engines: external combustion engines and internal combustion engines. An example of the external combustion engine is steam engine while an example of an internal combustion engine is the motor vehicle engine. The operation of both types of engines is based on their ability to make gases expand and then cool down. The higher the temperature difference between the gas at its hottest and its coldest, the better the engine works. Thermodynamic theories explain how ideal engines expand, contract, heat and cool gas in a series of steps called a cycle.

Steam Engine

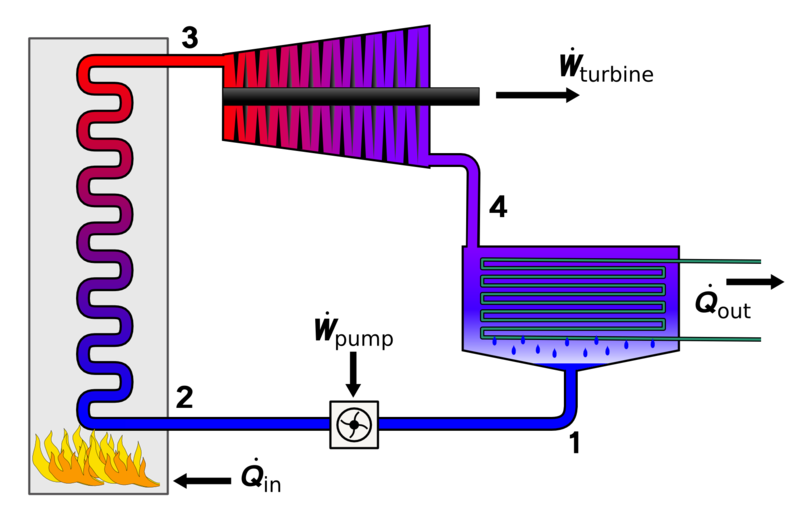

A steam engine is a heat engine that uses water as a working fluid to perform mechanical work. As already mentioned, steam engines are external combustion engines because the working fluid is separated from the combustion chamber. Fortunately, the source of heat in a steam engine is not limited to burning fuel components. The heat may also be derived from other sources such as nuclear power, solar and geothermal energy sources. The process used to analyse steam engines is the Rankine Cycle. The Rankine cycle is an idealised model which is used to predict how steam-powered heat engines generate power.

Apart from the problems of heat loss between the combustion chamber and the piston and heat lost through the exhaust, there are other problems with the steam engine but among these only two are apparent. First, because steam is dropped from the cylinder each time the piston pushes, the steam engine consumes a lot of water, and this is counter-productive in locomotive train applications. Secondly, the boiler which produces steam operates under high pressure, and there is always a risk boiler explosion which is an important safety issue. Apparently, the steam engine needed improvement. The improvement came in the form of the Stirling Engine

Stirling Engine

A Stirling engine is a closed-cycle regenerative heat engine that works through a cyclic compression and expansion of air (the working fluid).

A Stirling engine helps to overcome the problems of steam engines listed above. It does this by eliminating the need for the boiler (thereby eliminating explosion risks), using the fire directly to power the engine directly. The energy loss challenge is resolved by sealing the working fluid in a closed pipe so that the same air moves back and forth endlessly, picking up energy from the heat and releasing it inside the cylinder. By using a regenerative heat exchanger, we can retain the energy in the hot air inside the machine, thereby improving the efficiency of the engine. In other words, for each cycle, the available heat is not released through the exhaust as was the case with steam engines. Rather, the heat is retained and reused through the regenerative heat exchanger. These are some of the ways that the Stirling engines solve most of the problems of the steam engine. Now we can examine exactly how the Stirling engine works.

The Stirling Engine By Parts

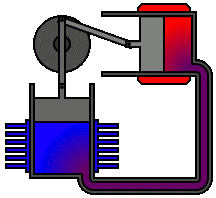

The image on the left shows one design of the Stirling engine, and it is called the Beta-type. It has two different pistons but only one cylinder as shown in the image.

The loosely fitting piston is called the displacer piston, sometimes called the displacement piston which is different from the tightly fitted work piston. We shall subsequently examine how the different parts make the engine work.

The Heat Source

Even though the Stirling engines are described as an external combustion engine, they do not have to burn any fuel to produce mechanical work. AS was mentioned at the beginning of this post, heat engines take advantage of the difference in temperature to operate. Therefore, the heat source in a Stirling engine could be real heat from burning fossil fuel or heat from the sun obtained using a solar-focusing mirror, geothermal energy source or any other energy source that can provide sufficient temperature differential between the source and the sink. Because the engine only needs a differential in temperature, the heat sources that can drive a small Stirling engine could be amazing. A cup of hot water could be sufficient to drive a small Stirling engine, but then because of the law of conservation of energy, the work done from such a source is usually quite limited too. The heat source is shown in the lower, red part of the image shown to the left.

Heat Sink

We have to still refer back to the temperature differential requirement in the engine and note that apart from the heat source, there is the need for a heat sink. The sink is basically where the hot air is cooled with the use of metal fins that helps to expels heat to the surroundings or sent back to the regenerative heat exchanger. The heat sink is usually a form of radiator. This part is indicated by the blue upper part of the image of the beta-type engine shown to the left.

Working Fluid or Gas

The purpose of the working fluid is to pick up heat from the heat source and transport the heat to drive the piston then get cooled at the sink and sent back to pick up more heat so that the process is repeated endlessly. The principal requirement of the working fluid used in the Stirling engines is that they remain gaseous as they pass through the heating and cooling process. Unlike steam engines, the working fluid in Stirling engines does not need to go through a phase change while permanently sealed in the engine's closed cylinder. Some suitable gases are hydrogen, helium, or ordinary air.

Working and Displacement Pistons

It may already be obvious to you that Stirling engines always have two pistons. The image of the alpha-type presented earlier has two pistons in two different cylinders while the beta-type shows two pistons in one cylinder. Since we are looking at the workings of the engine through the beta-type, you will notice that the engine has two pistons. The displacer piston fits very loosely inside the cylinder and its function is to move gas between the heat source and the heat sink. The tightly fitted piston is called the working piston and its job is to convert the expansion of the hot working fluid into actual mechanical work. As shown in the image for the beta-type Stirling engine, it can be seen that both pistons are attached to the same wheel but they are 90 degrees out of phase with each other, and this keeps the engine operating smoothly.

The Regenerative Heat Exchanger

As the name implies the regenerative heat exchanger sits between the heat sink and heat source and traps extra heat that would have otherwise been lost to the surrounding as the piston moves past the heat exchanger. The heat exchanger gives back this heat as the piston returns, making it available to be used. This makes the engine more efficient.

Conclusion

The Stirling engine was invented by Robert Stirling in 1816. The technology has been used and abandoned a few times since then but it is recently gaining popularity is solar power applications as fossil fuel deposits are dwindling and concerns for the negative effects of Carbon dioxide on our environment. Stirling engines convert heat energy to mechanical work by repeatedly heating, expanding, cooling and compressing the working fluid. Each set of these operations is called a Cycle. When you realise that the heating part of the cycle expands the working fluid and that the cooling part of the process, compresses the working fluid, then it becomes apparent how the piston gains the energy that enables it to do mechanical work.

Stirling engines are ideal for use in Combined Heat and Power (CHP) cogenerationplants because of their ability to generate power continuously using the difference between hot and cold conditions. They are also used in solar power plants where the Sun's heat is concentrated using solar mirrors and used as heat sources.

Perhaps, the most exciting application of the Stirling engine is using it in reverse. If you are conversant with electrical machines, you will understand that electric motors can be used in reverse to generate power. Similarly, we could reverse the Stirling engine by running it backwards. This just means that instead of taking energy or mechanical power from the engine, we can supply the engine with energy so that it can remove heat from the sink and expel it at the source. This makes the Stirling engine into a very efficient cooling device called Cryocooler.

References

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details. You can also check this blog post by @steemstem here and this guidelines here for help on how to be a member of @steemstem.

Being A SteemStem Member

This is where the price of fuel in the engine working on the piston causes the movement of solid parts, eventually the car. This became possible because the British empire that used steam engines and then developed using coal to push the piston and then eventually generate rotary (movement) to move the engine.

But the inventor of his own is not in it, then who is the inventor of a pioneer of a scientific inventor in this machine? Many basic modern automated systems first came from the Muslim world, including the player connecting the system. With the twisting movements with straight motion, the player allows heavy objects to be lifted relatively easily. The technology was founded in the 12th century, then this theory is used in bicycle use today.

Crankshaft is a device that translates into a linear spinning motion and is the center of many machines in the modern world, not least an internal receiving machine. One of the mechanical inventions in human history, was created by an ingenious Muslim engineer known as al-Jazari to raise the air for irrigation.

His book of Knowledge of Intelligent Mechanical Devices (1206) shows he also discovered or used the use of valves and pistons, composed the first few mechanical hours by air and, and was the father of robotics. One of his 50 inventions is a combination lock.

Taks for sharring.....Your post is always full of science in it.

Thank you for your reply. You're right that most times we talk about and use these technologies without mention of the inventors who worked so hard to invent them in the first place. However, because the problems facing humanity at every stage in human evolution are often the same all over the world, scientists and forward thinkers, grapple with these problems from their own corners.

Incidentally, more than one persons may end up discovering one thing or inventing one machine. However, it is only those who document and popularise their own scientists that are recognised as the originators. So I thank you for making it known that the Muslim world did much in the area of inventing machineries and engines.

It is always a pleasure to have you here.

This is more like a re-explanation of my MCE409 class....

Engine esp the internal combustion engine are popular topics of interest. However, external combustion engines like the Stirling engine are also as important and as said, are gaining popularity especially because solar power systems are also gaining presence and are being widely used these days. So, it deserves more attention as well.... Thanks for walking us through this. It was a nice read - worthwhile.

Keep writing sire

Thanks Bro. I decided to try my hands in your field. I hope I didn't disappoint much. Yes I like the sensitivity of the Stirling engine because it means we can achieve results with just small differences in temperatures between the heat source and heat sink.

Thanks for being here.

You are so vast and well knowledgeable. I can even say you did quite better than expected.

Yeah, it's quite a remarkable improvement on the operation of the steam engines.

Thanks man for the vote of confidence.

Reading reading and reading through I have picked up one or two pieces of knowledge✌

Thank you.

Another great post @churchboy!

I've always wondered if the cooling cycle could be enhanced in a Stirling engine by using liquid nitrogen.

I've even wondered if liquid nitrogen could be used to operate a Stirling engine. Liquid nitrogen has an in incredible capacity for thermal expansion, so if you could find a way to make it run without freezing solid it could be a viable prospect.

Thanks a lot. You are too kind.

Congratulations! Your post has been selected as a daily Steemit truffle! It is listed on rank 11 of all contributions awarded today. You can find the TOP DAILY TRUFFLE PICKS HERE.

I upvoted your contribution because to my mind your post is at least 34 SBD worth and should receive 102 votes. It's now up to the lovely Steemit community to make this come true.

I am

TrufflePig, an Artificial Intelligence Bot that helps minnows and content curators using Machine Learning. If you are curious how I select content, you can find an explanation here!Have a nice day and sincerely yours,

TrufflePigThank you. I appreciate the selection

The advent of internal combustion engines (I. C. E's) has limited the application of steam engines today. I. C. E's are compact and more efficient than steam engines. However their inherent problem is the emission of hazardous gases, which is why engineers are looking for better options.

The sterling engine eliminates the problems of steam engines and produces no emissions.

I believe this is an area with the potential for future energy supply. Thanks for the insight. Keep it rolling.

Thanks a lot Temitayo. I appreciate your comment.

You are highly welcome.