YOUR ENGINE IS NOT A STATE, BUT IT HAS A GOVERNOR(An insight into how engine speed is maintained)

Hunting, yes, hunting, it's an all too familiar word, right?, that you've heard countless times and have used for an equally countless number of times. If it's the compulsory question in your examination and it carries half of the whole examination's marks, I'm sure you'll be ecstatic to answer it and take the "free" score.

Please, correct me if I'm wrong, but I'm thinking that your answer in that examination will be a definition of hunting as the act of chasing animals to kill or capture, or as the act of chasing people down for different purposes. Well, if I guessed your answer right, then, you better be glad it's not a mechanical engineering examination.

Don't pick up your dictionary just yet, neither should you make an online search for another definition for hunting, I'll tell you, but, you should know, this one involves an engine, in fact it can happen inside an engine.

Here it is, a variation of something like engine speed around a particular mean value, of course this variation may be upward or downward, is how the Collins dictionary defined it. This is what your engineering examiner would have wanted you to start with.

However, he would have wanted you to explain further, that, due to the fact that the load on an engine changes from time to time, there will be an increase or decrease of the engine speed as a response to the load change. It is an undesirable occurrence though, for if you happen to operate an engine, say for example as a driver, the only other hunting you can possibly hate more than engine hunting is the hunt for your precious life.

At this point, if I say the very next word on my mind, those not familiar with engines may think I'm on a mission to simply confuse them, but be sure that I'm only here to share my knowledge about something that you use so well without knowing, for without it many of your engines, be it in your cars or generators, will not function properly.

Well, now that the air has been cleared, let it not be shocking to you that the device that makes sure you don't get disturbed by hunting in your engines is called a Governor, yes you read that right, a governor in an engine.

Well, we shall be talking about what governors really are and how they work, including their various types, not forgetting their usage. I'll try my best to govern you through the details without boring you with any type of hunting, so, please, fasten your seatbelt and let's take a ride to knowledge's palace.

In very clear and unambiguous terms, the Merriam Webster Dictionary defined Governor as a device attached to a machine to automatically control or limit speed, temperature or pressure. It should be noted that in this post that we will be focusing on the governor's used for speed control. However to limit ourselves to that definition will be to do a great disservice to the depth of the governor's contributions.

The governor's main job is to regulate the speed of the engine, it works in a way that it can know the amount of load variation by using different means, and adjusting fuel supply to compensate for that exact decrease or increase in load. Details will be provided about this later.

The different means by which these governors know the engine speed and effect change in fuel supply leads to their various classifications that are explained next.

Based on their working principles, governors can be broadly classified into the following categories :

- Centrifugal Governors

- Pneumatic Governors

- Inertia Governors

- Electronic Governors

The first three categories are generally referred to as Mechanical Governors.

To explain these categories in detail requires a lot of technical explanation that may eventually shroud the main point and thus lose the import of this whole post in the process. So I will stick to explaining only the very important details while providing an avenue for further research into any interested area.

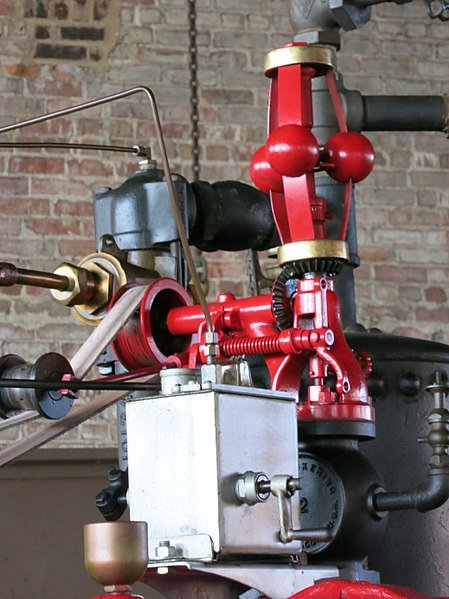

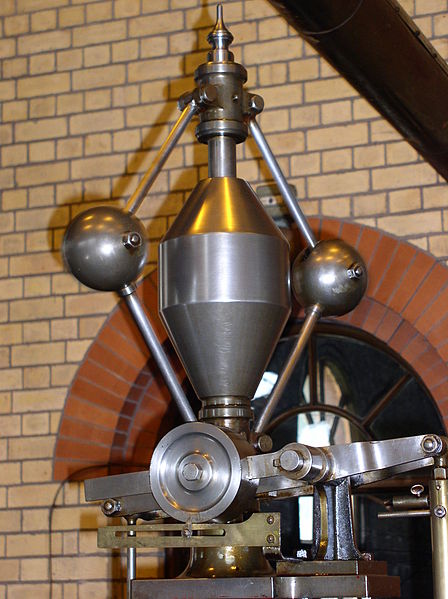

However, a very general feature of all the mechanical governors is that their main axis of rotation is connected to the output shaft of the engine on one end and the other end (output end) is attached to the throttle valve such that its consequent movement directly affects the speed.

To start with, I will explain the major working principles of all the categories.

CENTRIFUGAL GOVERNORS : this is the broadest category of all. Governors in this category are majorly divided into two :

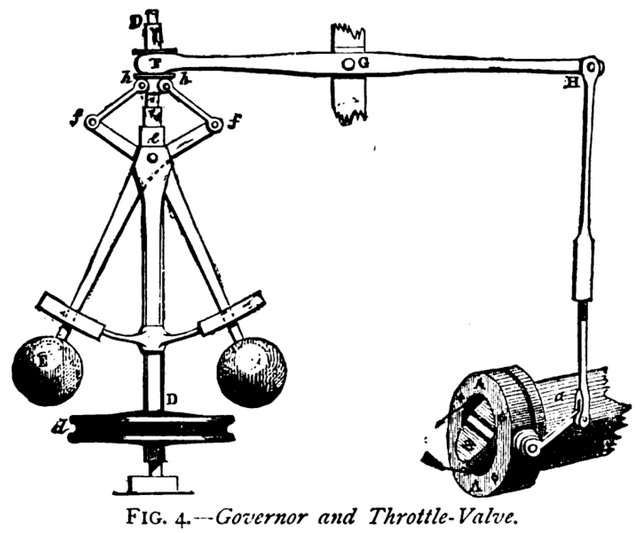

Dead-Load type : These operate based on the arrangement and movement of loads in the form of balls. These balls are attached to sleeves, these sleeves are then attached to the spindle on the main axis of rotation of the governor. Say for example, an engine was operating at mean speed, however there was a decrease in the load it is carrying, the engine speed normally increases, therefore, since the governor is attached to the output shaft, the governor's speed also increases, at this increased speed the balls and the sleeves rise such that this rise pushes the bell crank lever arrangement connected to the throttle valve to reduce the amount of fuel supplied as shown in the image above. An exact reverse of this process occurs in the case of increased load. Types of loaded governors include: Watt governor, Porter Governorand Proell Governor.

Spring-loaded type : These work by using an arrangement of balls on sleeves,both having their movements controlled by the movement of a compressed helical spring. The bell crank lever connected to the throttle valve carries the ball on one end and is then hinged by a pivot of rollers fitted between the sleeve. The sleeve itself is located below the spring casing. The increase in speed causes the ball to project outward from the governor's main axis, but because the ball's movement is restricted, thus the pivot moves the sleeves upward against the spring, resulting in partial closing of the throttlr valve, hence lower fuel supply and consequent speed reduction. Types of governors under this category include : Hartnell Governor, Hartnung Governor, Wilson-hartnell Governor and Pickering Governor.

INERTIA GOVERNORS : These also involve the use of loads in form of balls, but these balls are arranged such that their positions are altered by the inertia forces resulting from the angular acceleration or angular retardation of the governor.

PNEUMATIC GOVERNORS : they are relatively simple in design. It uses an assembly of air vane connected to a spring and the spring is connected to the throttle. The air vane is mounted in the engine's blower housing. When the engine is at mean speed, the spring pulls the throttle to open regular fuel flow, however, when there is increase in speed, air from the blower forces the air vane against the spring, thus reducing the opening of the throttle, hence reduced speed. This process is also reversed in the case of low speed. These types of governors are not usually as accurate in operation like others.

ELECTRONIC GOVERNORS : In this case, the throttle is linked to a servo motor. The ignition system of the engine emits electrical pulses which vary according to engine speed, these pulses are counted by an electronic module which is connected to the servo motor, which in turn proportionally control the opening and closing of the throttle.

arrangement of governor and throttle

APPLICATION OF GOVERNORS

Governors find application in various fields where engines are used. For example, small engines like those used in lawn mowers, garden tractors make use of governors to ensure that they do not go beyond a safe speed limit.

Also, water turbines and steam turbines including aircraft propellers make very good use of these governors.

Generators powered by engines also find very good application of governors due to the fact that they have very little tolerance for speed variation.

Many may notice that very few cars make use of governors, this is so because the human drivers do what you can refer to as manual governing by determining when and when not to throttle and adjust the speed.

However, if you've driven long distances, or know someone who has done so, perhaps you know someone who has driven manual transmission vehicles in traffic jams, and you've heard the drivers complain about how much stress the constant speed adjustment and focus requires, you will truly appreciate how much service these governors render to us even in our absence in the case of unmanned engines.

It should be noted that these different types of governors vary in their sensitivity and application, but when properly used, they save engine operators and end users a lot of unnecessary stress and damages and you can be sure that they govern aright in the real sense of the word.

Yes, they are also quiet heroes, unheralded, maybe, but indispensable they certainly are.

REFERENCES

For further enlightenment, please visit :

CENTRIFUGAL AND INERTIA ENGINE GOVERNORS | ELECTRONIC GOVERNORS | GOVERNORS AND IT'S TYPES | CENTRIFUGAL GOVERNORS

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details. You can also check this blog post by @steemstem here and this guidelines here for help on how to be a member of @steemstem. Please also check this blog post from @steemstem on proper use of images devoid of copyright issues here.

A journey into the inner chambers of an engine but you concentrate on the mechanical control system. Nice anyways.

Thanks, I'll see to that.

Seriously what?

Well all in can say is you got me hunting for the memories that governed my second year in the university!

One question sir,

Very well, yes. Engine-powered generators for example can't do without their regulation.

Governors i remember arguing this with one of my lecturers in school. He said i was wrong because governors are not used in ic engines but steam engines. I don't know. But was he right?

Steam engines had their time, but are now majorly replaced by Internal Combustion Engines, and the applications mentioned above are used in these IC Engines. Steam turbines are an evolution of steam engines too and they also use governors.

We are both right then... But he was too insistent like he was so sure like IC engines don't use them at all.

jejej is great

With the absence of a governor, you would need to adjust the throttle manually each time your lawn mower ran across a dense patch of grass or the engine will stall. According to your post, the governor does the job for us by detecting changes in the load and adjusting the throttle to compensate, if I'm not mistaken @sogless

Without a governor or manual adjustment, the engine will try to compensate for the load by reducing the speed, this normallyresults in increased torque, however like you mentioned, if the patch is too dense in the absence of either governor or manual control, it will stall until you move it away from the patch and then it resumes work with a sharp increase in speed. The latter point however is the main reason why lawn mowers have governors, to ensure that no matter the reduction in load, it doesn't run above a certain speed limit.

Thanks for this ... Kudos

governors these days are not implemented majorly from mechanical point of view but electromechanical angle though you spared nothing in your explanation. Nice one bro

Thanks for taking the time to read through and making that salient point.

Being A SteemStem Member