The Forest - Wilderness, Requiem, Laboratory? How Cellulose Is Reinvented

Everybody has at least seen a tree in their life. Trees have provided resources for mankind for thousands of years. However, researchers found a way to make a new super material from trees, or just about any plant. And it all is based on a naturally occurring polymer, which until recently, I found very unspectacular. Today I want to introduce nano-cellulose, a super material with big potential, and a seemingly endless supply.

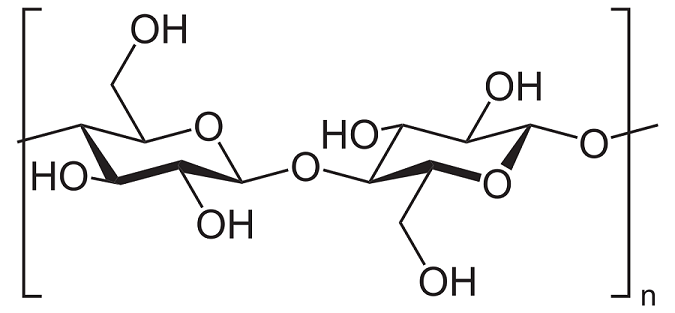

What Is Cellulose?

Cellulose is one of the main components of wood and consists of a chain of sugars. While humans are unable to break cellulose into glucose (this is due to the fact that the chain elements of cellulose are linked in a different way than in starch for example), many animals like cows can use it to get the glucose they need. It is an abundant substance, as every plant has it. Cotton fiber consists of 90% cellulose, while wood and dried hemp are at roughly 50% (1). So there are many sources cellulose could be obtained from, like plant waste, etc.

What Is The Fuzz About?

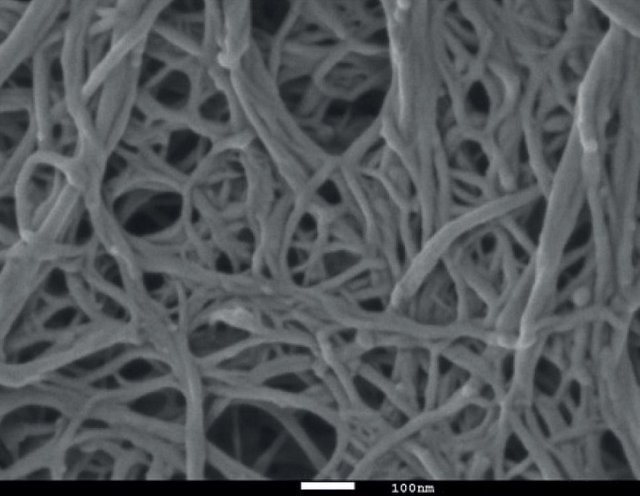

Wood is a very rigid structure, and part of it is due to cellulose. Now imagine a way that we can use that rigidness of cellulose. Science is doing exactly that, and by deriving mechanisms to yield cellulose crystals, we are able to produce large amounts of nano-cellulose. Thus, it is readily available to us. Nano-cellulose is produced by mixing wood-pulp (basis for paper production) with sulfuric acid. This mixture is then diluted and neutralized before separation of cellulose crystals is performed (2). There are several trial plants in the world that are trying to increase the yield of nano-cellulose, demonstrating the industrial and national interest in this material.

And this is very the magic begins.

In combination with other polymers, nano-cellulose can be used as water filters for compounds that are found in very small quantities in water. This paper demonstrates a way to modify nano-cellulose to produce a model for a water filter that is capable of filtering our contaminants of growing concern. In this paper, they state some advantages of nano-cellulose (NC) in comparison to previously used materials.

NC is primarily obtained from naturally occurring cellulose sources and are getting considerable attention because they are inexpensive, biodegradable, and practically renewable, making them sustainable and nontoxic materials for several applications

In addition to above characteristics, they are also very strong, have a high surface area, and reactive groups present on their surface, which enables extensive modification by addition of other groups (3). They lend themselves as carries for other functional materials, for example in bendable solar panels (4).

Composite materials (materials composed of nano-cellulose and another compound) can be crafted to yield materials that are able to respond to changes in their environment such as pH (5). This will help to develop highly-specialized functional materials that have certain characteristics under one condition, and then others when changes occured.

Nano-cellulose also offers promise as a material for biomedicine. It has been shown that it has lower cytotoxicity compared to other nano materials like nano carbon tubes (3). Because of this, and other characteristics (such as biodegradability and biocompatibility), nano-cellulose has recently received interest in biomedicine, mainly as a drug-delivery agents or as scaffolds for regenerative medicine (3).

Due to their small size (nano scale), and their strength and durability, they have been used to increase the stability in aerogels and hydrogels (6). Aerogels and hydrogels are very light compounds with surprising resistance to force. They are composed of almost 98% of pores, meaning most of their volume is air (7). This picture shows a 2.5kg heavy stone placed onto a 2g heavy, almost invisible aerogel.

Source

Such gels can be produced from nanofibrillar cellulose hydrogel, by dissolving nano-cellulose, and then by stirring and freezing the resulting gel(8). Through this process a blueish gel turns into an almost invisible, very light yet very strong material.

I also want to share with you this TEDX talk, given by Vegar Ottesen, who might convince you that nano-cellulose may be saving the world from plastic waste. Anyways, he is a good speaker so this is just an enjoyable video.

My Opinion

Nano-cellulose has the potential to become an all-round, biodegradable material. It has many potential applications and can be discarded and recycled very easily, without any harm to nature. Additionally, as long as there are plants on this planet, we will have cellulose available, and thus we can produce nano-cellulose. I am particularly amazed by the opportunities it offers as functional surface. A bio material that can carry functional groups, or even enzymes, may have a great future in bioengineering and medicine. However, as a chemist, I am eager to see if we can use nano-cellulose for the design of flexible instruments, possibly even as a basis for printable instruments (for example for certain spectroscopic techniques). Personally, I will follow the development of nano-cellulose and keep it in mind as I am perusing a career in instrument development and surface chemistry.

Shameless Self-Advertisement

Thank you very much for reading this post. I am very appreciative of thoughtful comments and I will reply to those that give good comments (also you will get an upvote). If you just write something like “good information”, I will ignore your comment.

If you have suggestions or found something that I missed or messed up, please let me know in the comments so I can fix that, and not make the same mistake in later posts. I am also writing a series about Chemical Instruments, Genius and Madness and about my current research efforts. There are currently no new posts in the Lab Chronicles, because the work I am doing right now is very repetitive. I will write a new post once I got some promising data! Thank you again!

As always,

Cheers @lesshorrible!

I have a question

As you said these hydrogels are biocompatible and of course being a biopolymer it should most likely be biocompatible. But at the time of preparation of these hydrogels, one must reach the pH of around 13 to dissolve these cellulose fibres and with this basic pH, it will never be biocompatible. People have tried by either washing the hydrogels with water to remove the excess base or they have used urea or NMMO. But again using such chemicals to lower the ph to neutral is not beneficial for the cells.

What's your opinion on this? how these different cellulose (NFC, MFC, CNF) can be used for cell study. So, not have any biocompatibility issue.

Hey @vinamra. Thank you for your question! I did not say that hydrogels are biocompatible, but nano-cellulose is.

Cited from this source. I hope this answers your question.

Cheers!

excellent post friend already voted