How we generated $2450 in sales in just two weeks!

Sometimes building a great business is not so much about being creative and innovative but about filling an empty space in the market. That’s kind of what happened to us with AK Frames. Here’s a little background:

I’m going to talk about drone racing. For those who are not familiar with this fast growing nerdy trend, these are basically quadcopters (and even tri- and hexacopters) equipped with an FPV camera that provides live video feed to the pilot, who struggles to run across different obstacles and environments as fast as possible without crashing. You can find some videos here.

I had been flying my new racing drone for some months when this idea came to my mind. My friend Asier and I would meet over the weekends to set some circuits up and have fun together. But more recently, we had been spending a lot of time discussing about different configurations to make our drones faster and more agile. So we sat down and wrote a list of must-haves for the perfect racing quadcopter. We both agreed that the most important part -and the one we could have access to- was the frame (think of a car chassis): the structural support of all the components.

After a little research, I couldn’t find any frames that met our strict performance criteria. We started sketching a few concepts and throwing some lines around on AutoCAD.

The design

I started testing different shapes and configurations on AutoCAD we printed at our home-made 3D printer, which isn’t perfect but provides us a nice way to put all the parts together and see how it works. Once we found a design we liked, we printed it on better quality, and Asier gave it a beautiful paint coat that looked extremely cool. We decided to take it to the first Spanish national meet of drone racing pilots to ask for advice and show our work to our friends.

Thanks to their feedback and the knowledge we were acquiring reading different forums -yep, they still exist- and blogs, we modified the design again and added new features I won’t spend time describing.

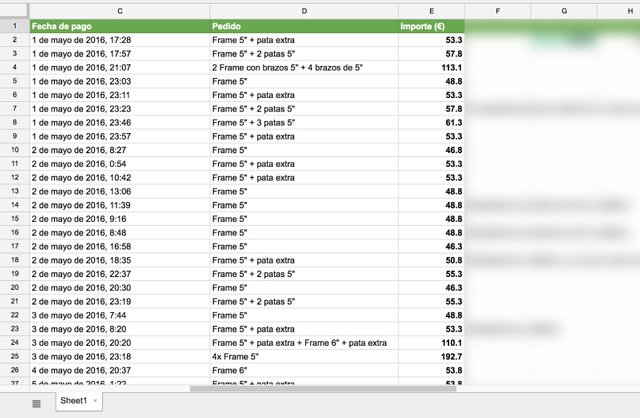

With the help of Luxion KeyShot I was able to do some renderings and send them to some friends. To our surprise, they all seemed to like it and started asking for a real carbon fiber product. Alberto, who was also interested in drone racing frames and owned an aerial filmography company offered us his help and his workshop to produce a fiberglass prototype. We couldn’t resist and visited him that same afternoon. The CNC cut turned out incredible! We took some photos with our phones and opened a thread at a Spanish forum showing that to the people.

As a designer I couldn’t prevent myself from designing a little logo and some branding assets to lighten the thread a bit more.

Manufacturing and samples

In the meanwhile, we started negotiating with different carbon fiber manufacturers from Alibaba about samples, pricing, shipping costs, etc. I’ll write a more detailed post on this process soon. If we were to produce this frame we would need the exact same quality we were hoping to get for ourselves. Here’s one of the most crucial points of every product’s success:

Whatever you make must be something you want to use for yourself.

We contacted them and they seemed to understand the project and were interested in helping us. Later we found that they were also working for one of the highest quality competitors, which was calming for us.

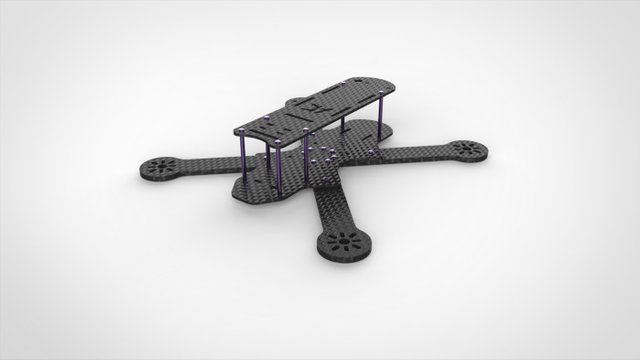

For the first batch, we ordered 6 units that were already pre-sold to our friends at factory cost in exchange for a detailed review of every aspect of its performance. It took two long weeks to arrive. However, once it was there the result was super satisfying. Building my own physical product was a dream come true.

Badass carbon fiber quality ❤. Note some intentional variations from the previous design.

The production price was still pretty high, although the Chinese sales manager promised to revise it in future orders according to the quantity.

Pre-sells

By the time of arrival, we had already opened a pre-order thread in the same forum to see how many people would be interested on it. Surprisingly, we received over 2000 views and 40 requests in less than 3 days. In my opinion, one of the facts that helped more was our reputation at that forum, since Asier and I love participating in the debate, watching and sharing other pilots’ videos… For the first time, we were allowed to truly use the sentence: “built by [x] for [x]”.

As much as building a great product matters, it’s the actual selling that makes people want to buy it. And I can’t be more thankful for the work my partner did on the marketing side. He took the time to personally chat with every customer to hear their thoughts on the product and convince them to get one -or more- of our frames.

Personal communication is key, specially when the customer is about to pay out a great amount of money.

The response from the community was overwhelming, we had crossed the point of no return.

Again, we emailed the Chinese manufacturer and they were extremely happy to hear the good news. In fact, they offered us a much lower price that made it all possible. Now, with a carbon fiber manufacturer and many possible customers, we did some maths.

We put together all the costs, which break down like this:

- Carbon fiber plates (8 in total) + shipping + customs taxes

- Screws, hex bolts, aluminum spacers + respective shippings + customs taxes

- Packaging, stickers, extra velcro straps

- Shipping to each customer

And it still excludes PayPal fees, replacements, lost packages… Certainly, we were scared of so many things that could go wrong. Once we had the numbers, we wrote a pre-sale post on the same thread which lead us to the next step.

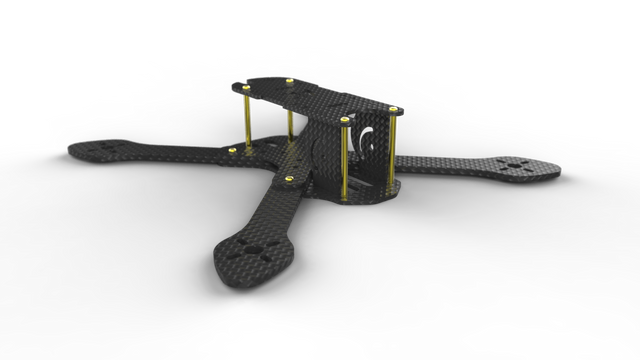

The actual selling

We were concerned about some possible customers stepping down and canceling their pre-order, but luckily almost everyone who signed up on our listed finally ended up purchasing one frame. And some who weren’t on that list did as well. In total, we received 40 orders in 4 days before we decided to close the sale to speed things up and avoid losing too much customer money in case of failure. Some of our customers even ordered 3 or 4 frames per person!

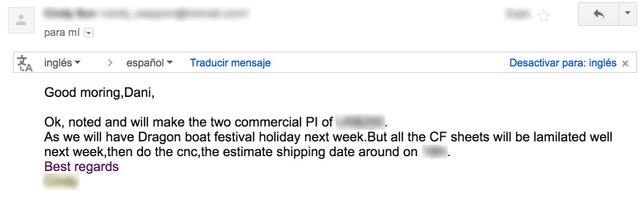

At that time we could already speak of success. However, we only had a bunch of dollars from our customers and nothing to give back. We placed a massive order to our manufacturer and he gave us an estimate date. Here’s where we encountered a big problem. We were hoping to send them to our customers weeks before the Spain Drone Nationals to allow them to bring our AK frames to the race. But the estimate date was too close to this event.

Literally pooped our pants when they told us they’d be on holidays…

After some -kind and respectful- pressing I was able to speed manufacturing up and receive the frames on time. Still, some screws and spacers were delayed and/or cancelled, so again things got quite tight.

Even before all the orders were fulfilled some customers were contacting us to order more units. Unfortunately time was over and the race was too close.

So… did you actually make it?

Indeed we did! We went to the race with our own frames half-tested (Asier spent the night before the race assembling a few more, just in case) and some friends raced as well with them! Watching others fly with something you had done is the most uplifting feeling.

I crashed in the top 64 heat and got eliminated, but I was still happy to see that 3 of the 8 pilots on that round were carrying our drone. The frame performance was incredible, beating in speed and corners some of the best pilots. Huge success!

Let’s talk about numbers.

The price we set left us little-to-none profit per frame. Otherwise most of the sales wouldn’t have been possible. The logic here is that we wanted to promote our project and get known before launching other products, opening our doors to a bigger audience. We sold each unit at a fixed cost of around $55, in which we included an spare carbon fiber arm, some stickers, a velcro strap and shipping. As you can see, there’s no room for profit. Or is it?

From our first calculations we had some reductions in price, lower custom taxes and shipping fees we were not expecting, and the spare units were sold a few weeks later for full profit.

Money that we didn’t keep, of course. We included a bunch of other prototypes for testing in the huge order, whilst some money was spent on the brand.

Congratulations @danialaez! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOPCongratulations @danialaez! You have received a personal award!

Click on the badge to view your Board of Honor.

Do not miss the last post from @steemitboard:

Congratulations @danialaez! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!