Building the Salatin Pen

When we started figuring out exactly how we were going to raise as much of our own food as we could, chickens was one of the first things we researched. As I had been told that we were NOT having layers, most of what I looked into was on raising broilers.

As much as I would have liked them to free range, our predator load is so high, the flock would have been gone in a week. We had read that some families used a whole chicken a week, so we figured 52, plus extra in case we lost some. We settled on 75 birds.

Early on, Joel Salatin’s books came on the radar, in particular Pasture Poultry Profit$. He had designed a low box measuring 10’ x 12’ that he put 75 Cornish Cross into for the 48 days of their life. We weren’t sure we wanted to do that, so we got 25 Cornish Cross and 50 heritage birds, all straight run.

More research turned up some flaws to his design. They were called Easy Bake ovens and they were relatively hard to move. They had no bottom, a predator hazard. There were no roosts, so they had to be moved at least daily. They were made with chicken wire, which raccoons love.

So we set about rectifying these problems. Our changes:

• Hardware cloth

• Diagonal bracing

• Vented back corner

• Bifold door entrance

• Double waterers

• Double feeders

• A wheel system

• Rounded corners inside

• A tarp for when it rained

• Inner tube stapled to the lower edge

• Handle in front to see the birds during moves

• Poultry netting on a dedicated charger

Mama raccoon peers down from the hayloft

Raccoons, with their little hands can reach right through 1” chicken wire, grab a chicken body part and rip it off. They are amazingly strong, especially if the hind legs can get purchase. Hardware cloth, ½”, will keep this from happening and also keep rats out. Raccoons, if they are big enough, can also destroy chicken wire, especially of it’s not stapled firmly on. So, hardware cloth and 1” staples.

The Salatin pen didn’t use horizontal bracing. If it had, when you pulled the pen to move it, that bracing could catch birds and injure them. So we went with diagonal bracing and over the course of 8 years, only 2 birds were hurt.

We were concerned about heat buildup in the summer, so we designed a vented back panel that could be closed. We decided to hinge the roof quarter diagonally opposite to the bi-fold quarter. It was still roofed as the rest, but lifted up about 8” and had 2 supports to keep it open. Regular window screen was stapled inside to keep chickens in, but without the intention of keeping predators out. It was easily closed during bad weather. This provided venting in hot weather.

The entry into these pens was just a hinged quarter panel. I dislike this style as it can come down on you when you are working in there. So we made a bifold top that would stay up when opened. It folded back and was supported by struts for the waterers. We used 2 sets of hooks and eyes to close it, one on each section. (Note: these hooks are not the best if a raccoon breaches the first defenses.)

We used bell waterers and during the summer, algae tended to plug up the filters. So we put up double waterers so they’d never be without water. We used a white 5 gallon reservoir to keep the water cooler. If the water got too hot they would not drink.

We designed and built 2 feeders, 4’ long, of 3” PVC pipe cut in half. These were hung on hooks from the ceiling and the height could be raised as needed. We put them back under the roof to keep the feed dry, but so it was still easily accessed. They also had a loose dowel across the top that spun, to discourage perching.

Having plenty of feeder space is crucial to broiler growth, as is plenty of water do they can digest the feed.

Salatin used a dolly he slipped under the back of the pen to facilitate moving them. This did not work for us. We added a wheel system we had found online.

It was a pair of 16” lawnmower wheels, a 2” x 4” lever, 2 bolts and string. When the lever was pressed down, the wheels lifted the back end of the pen off the ground 3-4”. The lever could be locked in this position with the lock bolt. After moving the pen, return the lever to the raised position and lock it in place with the bolt. When done moving, it let the box rest on the ground.

And that brings us to the next design problem. When lifted up, the small chicks scooted right out. So I stapled sliced inner tubing to the lower inner edge all the way around the box. It was about 6” wide x however-long-they were. When the box was lifted, it draped down, blocking the openings.

And while we are talking moving, we found it much easier to pull the box from the front where you could see how the chicks were doing, thereby avoiding injury. We put an old lawn mower handle on the lower front support.

Another design change was to round the inner corners. If there are no corners for the chicks to bunch in when they are cold, there’s less chance of smothering. We used hardware cloth in the front where there was hardware cloth and a piece of plywood in the back where there was metal roofing. We made sure the top of the rounding pieces was flush with the ceiling, so no chick could fall between the corner and rounding piece. Occasionally as we moved the pen, one would get in there and have to be chased out.

The first serious rainstorm we had at night took 7 of the chicks. They had roosted on the ground under the hardware cloth door and got wet and cold and died. So we got a 6’ x 8’ tarp and rolled that out if there was a chance of rain at night.

And the last change was to run a dedicated line from a dedicated charger to the pen for electronet fencing around the pen 24/7.

The design is a box, 12’ long, 10’ wide, and 2½’ high. It has wire on the entire front and ½ way down the sides. It has ¼ panel on the top that is wire. The rest of the box is covered with metal roofing. It has no floor. There are no roosts. And the idea is to keep it as lightweight but sturdy as possible.

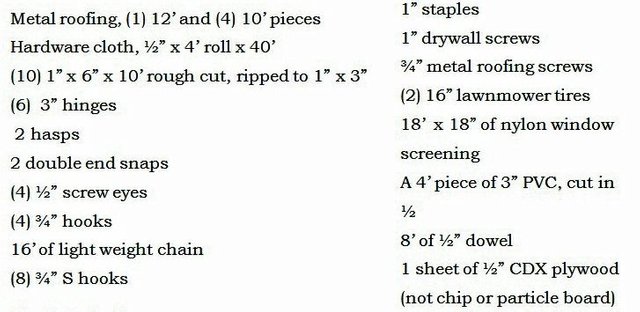

Here’s the Materials List:

You will want to go with the rough cut 1” x 6” and the trouble of ripping them to 1” x 3” for the added strength. Finish lumber of the “same” size will not have the strength.

For the support gussets, use only the plywood. Chipboards or particle boards do not have the necessary strength and durability.

Storing the Salatin Pen

This pen was not designed for snow load. It needs to be stored so snow does not build up on it. We tip it up so the wire front is up and the roof is against the barn. It is then tied against the barn.

We used this pen for many years. The problems we had were:

• It didn’t sit flush on uneven ground

• It was hard to move over rough ground or if the grass was over 8” high

• It was hard to get inside to catch chicks

• Filling the feeders was not easy even though we put them as near the opening as we dared

• We only used it for 3 – 4 weeks when the chicks we very small after our 1st year

• Even with the wheels and on smooth ground it was an effort to move it

• When the birds were nearly big enough to go to the bigger pen, but not quite, we had to move it twice a day due to manure buildup

• The wheel design broke down after a couple seasons of use.

So we designed a mobile coop. That will be another post.

Interesting!! I like the design. It seems very large and heavy though, but I supposed that is good for stability.

I've never done a chicken tractor, but I've considered it a few times. I ended up just letting my birds free range, as our property is fenced. That has its pros and cons though... I'd love to NOT go outside and step in chicken poop on my porch!

Very well put-together post!

It is sort of heavy but on flat land moved easily enough. It only has to move 12' each time.

I can not free range due to extremely high predator load here.

This was our first prototype, and we moved on from it to a couple others. I will be making posts about them in coming days.

Yes, I imagine only moving it that far is not a big deal.

I get that not everyone can free range. We got lucky and are in an area that is situated in a way that is sheltered from the wildlife. Our neighbors have predator issues, but not us.

Looking forward to seeing your posts about the updated chicken coops! :D

Wow! This is one heck of a write-up. I've built one of these before, but it wasn't this nice. Frankly, if I did it again, I'd build it out of steel, anyway. I think it would last longer and most likely be lighter.

Wow! You basically invented a whole new pen!! I liked the lawnmower wheels and handle...that was a nice touch :) I can't imagine having to move it twice a day, though!

Towards the end, neither could we! That's why we redesigned the coops....

Ah cool a chicken tractor is what we call it in Australia. Instead of raccoons we have to worry about snakes

we use the same method with our birds. your chicken tractor look awesome!