Learn with steem || Tutorial class 4 || Mechanical Engineering|| subject - Manufacturing process-|| by @deepak94

Namaste steemit

Hello friends, how are you all, hope all is well, today I am going to write my fifth post about my subject. Today in this post we discuss the Forging Process in the manufacturing process. So let's start with the topic.

FORGING

- Forging is the operation in which the metal is heated and then a force is applied to manipulate the metal in such a way that the required final shape is obtained and it can be useful for some kind of work.

- It is the control of the plastic deformation of metals at elevated temperatures.

- Because of the manipulative ability of the forging process, it is possible to control the flow in a specific direction so the best mechanical properties can be obtained based according to the specific application.

| Raw Material which can be forged |

|---|

- Plain carbon steel(1100-1250 degrees Celcius)

- Copper and its Alloys (750-925 degrees Celcius)

- Aluminium and alloys(370-450 degrees Celcius)

- Magnesium (315 degree celcius)

- Bronze

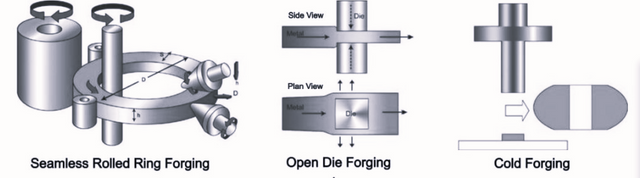

| Forging Type |

|---|

There are 4 types of forging methods that are generally used. These are

Smith forging

- This is the traditional forging operation.

- Done openly in open dies by manual hammering or by power hammers.

Drop forging - The drop forging dies consist of 2 halves.

- The lower half of the die is fixed to the anvil of the machines, while the upper half is fixed to the ram.

- The heated stock is kept in the lower die while the ramp delivers 4 to 5 blow on the metal, in quick succession so that the metal spread and fills the die cavity.

- When the 2 die halves close, the complete cavity is formed.

- Drop forging is used to produce small components.

Press forging - Force is a continuous squeezing type applied by the hydraulic process.

Machine forging - In drop and press forging the material is drawn out, but in machine forging the material is only upset to get the desired shape.

| Advantage of forging |

|---|

- Structure homogeneity.

- Porosity, voids, and blue holes in the metal are eliminated resulting in internal soundness.

- Coarse or columnar grain is refined, increasing its yield and ultimate strength.

- Better mechanical properties.

- The uniform structure permits higher machining speeds.

- Minimum metal remover in machining.

- Relatively smooth surface of the forging.

- Forging is within fairly close tolerance.

- Rapid duplication of components.

- Forging is easily welded.

| Drawbacks |

|---|

- In hot forging there is rapid oxidation or scaling, and poor surface finish.

- Tooling and handling costs are high.

- Many intricate and cored shapes objects cannot be forged.

- Forging cost more than castings.

| Forging operations |

|---|

Steps involved in hammer forging.

- Colouring or switching.

- Edging or rolling.

- Bending.

- Drawing or cogging.

- flattening.

- Blocking

- finishing operation.

- Trimming or cut off.

| Basic forging operation |

|---|

Upsetting

- Increasing the diameter of material by compressing its length.

- Employs split dies that have to contain multiple cavities.

Heading

- when the upsetting process is complete in such a way that the section of the stock is increased only on one end of the stock.

I hope you all liked this tutorial series of mechanical engineering subject and please tell me in the comments, what you liked in this quick tutorial series.

Thank you for contributing to #LearnWithSteem theme. This post has been upvoted by @Reminiscence01 using @steemcurator09 account. We encourage you to keep publishing quality and original content in the Steemit ecosystem to earn support for your content.

Regards,

Team #Sevengers

Greetings, you have been supported by @steemindiaa account for your post. This is the official community account for our Indian community on Steemit. For more information, please visit our discord channel.

Telegram ----- Discord