Learn with steem || Tutorial class 4 || Mechanical Engineering|| subject - Manufacturing process- Wire Drawing, Tube Drawing etc.

Namaste steemit

Hello friends, how are you all, hope all is well, today I am going to write my fourth post about my subject. Todays in this post we discuss about the Wire Drawing and Tube Drawing process in Manufacturing process. So lets start the topic.

WIRE DRAWING

- A wire by definition, wire is a circular with small diameters so that it is flexible.

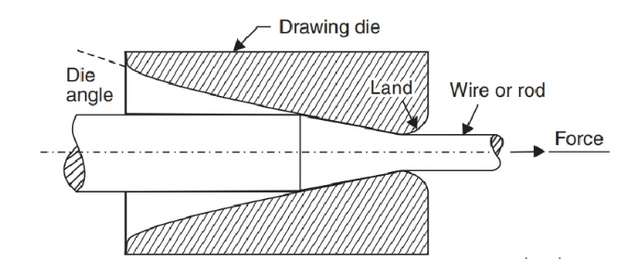

- The cold working process is to be obtain wires from the rods of bigger diameters through die.

- Same process as a bar drawing except that it involves a smaller-diameter material.

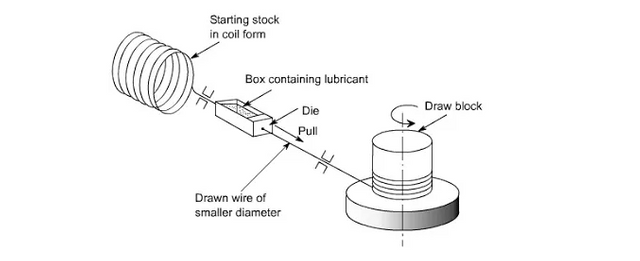

- At the start of wire drawing, the end of the rod or wire to be drawn is pointed(by swaging etc.) so that it freely enteres the die orifice and sticks out behind the die.

- Wire getting continuously wound on the real.

- For fine wires, the material may be passed through a number of dies, receiving successive reductions in diameter before being coiled.

- The wire is subjected to tension only. But when it is in contact with dies then a combination of tensile, compressive and shear stress will be there in that portion only.

- Wire drawing is always a COLD WORKING PROCESS.

- Die materials: tool steels or tungsten carbide or polycrystalline diamond(for fine wire).

- Drawing process is used to produce bright drawn bar and solid-drawn tubes.

- Main process of manufacture for the production of wires.

- For cold drawing purpose the material should be highly ductile.

- In cold drawing since the material being drawn become hard, it is given intermediate annealing operation between successive drawing stage in order to restore the ductility and therefore the capacity of the material for further cold work.

- The main aim of cold drawing.

i. Straighten it.

ii. Size it accurately.

iii. Give it a smooth bright surface.

iv. In some cases to control the strength and hardness in the final product.

NOTE

- The dye must be made of a highly wear resistance material such as diamond, tungsten carbide, high grade alloy tool steel or chilled cast iron.

- Wear- resistance value of tungsten carbide is exceptionally high.

- The pulling force which is required to the drawing operations range between 40% and 60% of the ultimate strength of the material.

Tube drawing

- Rod drawing is similar to wild drawing except for the fact that the dies are bigger because of the rod size being larger than the wire.

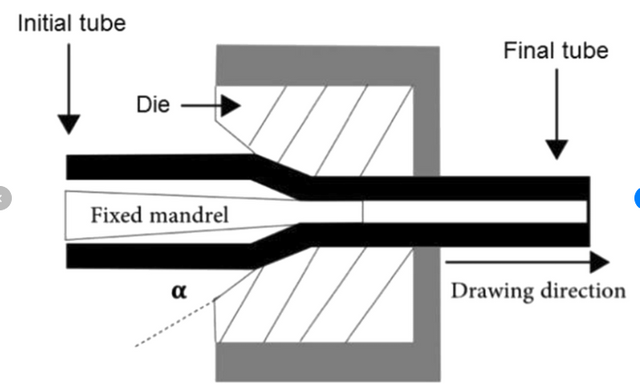

- The tubes is also be first pointed and then entered through the die where the point is gripped in a similar way as the bar drawing and pulled through in the form desired along a straight line.

- When the final size is obtained, then the tube may be annealed or straightened.

- practice of the drawing tubes without the help of an internal mandrel is called as tube sinking.

Conclusion |

|---|

Today in entire topic we learn about different mechanical deforming process in which we learn about wire drwaing and Tube drawing process.

I hope you liked this tutorial series of mechanical engineering subject and please tell me in the comments, what you liked in this quick tutorial series.

Thank you for contributing to #LearnWithSteem theme (#learnwithsteem , #tutorial, and #lesson). This post has been upvoted by @tucsond using @steemcurator09 account. We encourage you to keep publishing quality and original content in the Steemit ecosystem to earn support for your content.

Regards,

Team #Sevengers