WHAT HAPPENS DEEP DOWN INSIDE THE ENGINE CYLINDER; THE COMPRESSION IGNITION CYCLE.

Hello!

How are you all doing? As much as I am trying to hide my happiness I can’t just keep it to myself. This week has been a wonderful one as my supervisor DR. Mrs. S.I. Kuye gave her final approval on my undergraduate thesis work which I have been working on for close to two years and It has been an awesome journey. What made your week?

I remember some two years ago in my third year in school, it was mandatory for all students in the Engineering field to undertake an internship programme at any company or industry of your choice. I was not so lucky as I couldn’t get a placement at a big company as I had always hoped for. But what I did get was a gold mine to me as I walked into this gentleman’s workshop. the workshop had big and huge equipment’s that was used to repair, overhaul and maintain industrial generators.

After several days, I was quick to notice the diesel engine during an overhauling job. With every part loosened down. The cylinder head, camshaft, crankshaft, piston, connecting rod, gears, sump, fuel filter, oil filter, radiator and several other delicate parts of the engine.

But there was this little thing I noticed this engine didn’t have, could you guess what it was and why I was looking for this thing?

It was the spark plug. I had always known every engine to have a spark plug but this one was missing a spark plug so pardon me due to my ignorance at that time I never knew they were only being used for petrol engines. Why is this so? what ignites the engine as I asked my little self that day?

THE DIESEL ENGINE

The diesel engine is one of the powerful engines of the internal combustion engine they are known for their efficient works and high expansion ratio the diesel engine was named after Rudolf Diesel. These engines could be classified as the normal petrol engine except for that they don’t operate like the petrol engine. They are called compression ignition engines due to the compression of air-fuel mixture at a high temperature that causes combustion in the cylinders.

This happens due to the difference in their thermodynamic cycle. The diesel engine operates on a gas vapor cycle called the constant pressure cycle or the diesel cycle. Have you wondered how the compression ignition engine operates or why the diesel cycle is so special?

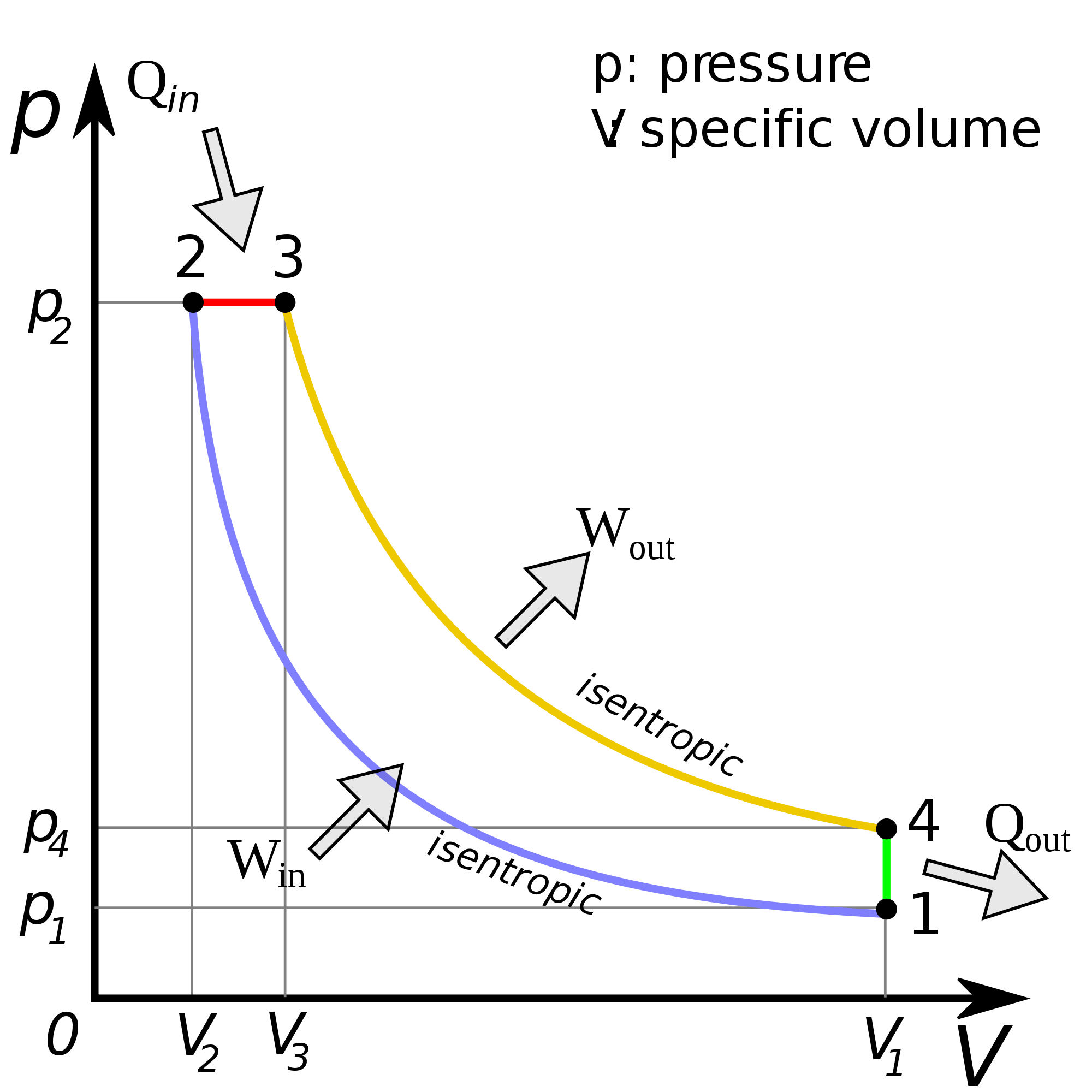

THE DIESEL CYCLE

The diesel cycle or compression ignition cycle is an ideal gas vapor cycle which diesel engines operate on (by the word ideal I mean certain assumptions have been considered). This cycle is similar to the Otto cycle I discussed earlier except for some slight difference in the cycle. The simple difference in the cycle is the method at which air-fuel mixture combusts.

The diesel cycle is another one of the four types of gas vapor cycles which are known to be thermodynamic cycles. Friction and viscous effects are also ignored in this cycle just like the Otto cycle and the use of injectors in replacement of carburetors are another special difference in the diesel cycle.

The diesel cycle is assumed to happen at constant pressure this is why it is also known to be called the constant pressure cycle. This cycle came to be four years after the Otto cycle in 1890, it was proposed by a man called Rudolph Diesel.

THE IDEAL DIESEL CYCLE EXPLAINED

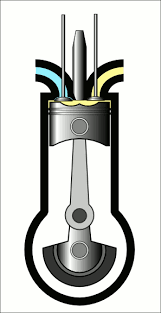

We would be considering a four-stroke engine to explain the diesel cycle. Four stroke internal combustion engines are engines whose piston completes four powerful strokes in their cylinder and the crankshaft also completes two revolutions to complete one thermodynamic cycle. Diesel cycle is explained in four non-reversible processes just like the Otto cycle.

ignition compression cycle from Wikimedia under CCO license

1-2 adiabatic compression process

2-3 constant-pressure heat addition process

3-4 adiabatic expansion process

4-1 constant-volume heat rejection

Process 1-2 (adiabatic compression process)

This process is called adiabatic because it occurs without transfer of heat. It begins when the piston travels from the bottom dead center (i.e. bottom of the cylinder) to the top dead center (top of the cylinder) compressing only air in the first stroke.

Process 2-3 (constant-pressure heat addition process)

Heat is added to the cylinder when the injector spills in through a nozzle adequate amount of fuel into the already compressed hot air this ignites the fuel and burns. Pressure is constant in this process.

Process 3-4 (adiabatic expansion process)

The burning of this fuel which occurs at high pressure pushes down the piston head to the bottom dead center (i.e. bottom of the cylinder) as expansion occurs.

Process 4-1 (constant-volume heat rejection process)

Heat is ejected out of the cylinder as the piston rests at the bottom dead center (i.e. bottom of the cylinder). The exhaust valve opens in this process as products of fuel combustion flows out.

THE ACTUAL COMPRESSION IGNITION CYCLE EXPLAINED

It is well known that the operation of diesel engines does not occur in an ideal environment as factors such as friction and viscosity are bound to happen. So, there is a slight deviation from the compression ignition cycle even if it works based on the cycle.

THE COMPRESSION STROKE

During the transition to this stroke, the intake and exhaust valves are closed, and the piston is located at the bottom of the cylinder (bottom dead center). As this stroke happens piston travels from its position at the bottom of the cylinder to the top of the cylinder and compresses the air at a high pressure which causes the temperature of this air to be very hot while both valves are closed.

THE POWER STROKE

As the piston approaches the top of the cylinder, with compressed hot air at a high and constant pressure which is above the temperature of autoignition the injector through a nozzle injects the right amount of fuel into this compressed hot air and boom! There is ignition in the chamber. The burning or combustion in the chamber pushes down the piston to the bottom of the cylinder, this effect rotates the crankshaft and completes the first mechanical cycle. The piston goes back to the bottom dead center (bottom of the cylinder).

THE EXHAUST STROKE

When the piston is forced down the cylinder by combustion in the power stroke, the chamber would have been filled up with products of combustion of fuel. The travel of the piston back up purges out the gases or product of combustion through the exhaust valve which will open up for the gases to go through.

THE INTAKE STROKE

Piston in this stroke will move back to the bottom of the cylinder and as this happens the exhaust valve closes as the inlet valve opens allowing for fresh air to move into the chamber for the process to begin again. This marks the end of another mechanical cycle.

APPLICATION OF THE COMPRESSION IGNITION CYCLE

Due to the high efficiency of the diesel cycle, the diesel engine is applied in various ways some of which include automobiles, air crafts, industries, household generators, factories.

They have the advantage of being rugged and a high fuel to power conversion ratio than the Otto cycle. Diesel engines have a low cost of maintenance and are great for industrial applications than the petrol engines.

WHAT HAPPENS WHEN YOU FILL A DIESEL ENGINE WITH PETROL AND VICE VERSA?

If diesel is filled in a petrol engine, and the engine is tried to be put into use the fuel of course diesel would be mixed with air but due to its heaviness and oiliness the diesel would not be ignited by the spark plug in the petrol engine. Therefore, the filling of diesel in a petrol will lead to engines failure to start.

Whereas filling petrol in diesel engines will cause a very combustible fluid with no oiliness to be injected into the hot air this would cause combustion. But the petrol burns prematurely which could lead to wearing out of engine parts called knocking.

CONCLUSION

The diesel cycle is a wonderful modification of the Otto cycle which does not use the spark plug for combustion in the chamber but rather compressed air at high temperature and pressure to cause combustion in the cylinder. There are few differences in the Otto and the diesel cycle which is mainly the use of carburetor in petrol engines while injectors are common with the diesel engine.

The diesel cycle was invented by a man called diesel and has more efficiency than petrol engines this is why it has numerous industrial applications than the normal petrol engines. Diesel should not be used in a petrol engine because the engine would not start. Also, petrol should never be tried in a diesel engine as it could lead to total damage of expensive engine parts.

Thanks for reading!

REFERENCES

For further reading please use the links and get the books.

- Thermodynamics chapter 8

- Thermodynamics: An Engineering Approach, 5th edition by Yunus A. Çengel and Michael A. Boles

- Engineering thermodynamics by R.K. Rajput

- Diesel cycle

- The diesel cycle

- thermodynamic cycle applications

- diesel engine cycle

- mechanical Otto cycle

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

Good to see the good old diesel engine explained. I always imagine my country without diesel-powered generators.. It'd be blackout everywhere at night.

Mehn! ... Diesel engines are life savers especially in Nigeria, I visited a power plant few months ago. They also run on IC engines and it was very clean.

Thanks for the comment.

That is awesome, I think I saw when you shared it here.

Yes it was a day that i decided finally on the aspect of engineering that i loved apart from my first love which is mechanical and electrical works in buildings.

Indeed, you gained a lot during your Internship programme.

Yeah i did. Thanks for reading.

So a man called diesel invented the diesel cycle, wow. Now i know why there is a fault in putting petrol in a diesel generator and vise versa. Great job.

Yes a man named diesel did... Thank you for stopping by to read.

Really do love that i learned something knowledgeable ,thanks.

Thank you for reading.

follow and vote

Being A SteemStem Member