Chocolate Production, From Beans to Chocolate Bars

Hello fellow chocolate lovers here on steemit. I just want to share hows the process of making chocolate. I believe that chocolate has health benefits too, like reduces stroke risk, controls cough, strengthens our brain and it may prevent cancer.

Lets start from the tree of the cocoa (kakaw in tagalog)

The cocoa tree is only grows in the tropical heat of the equatorial forest. The shadow of the tall-growing plants protects the young tree against the burning sun or strong wind. After five years, it is strong enough to survive and start producing cocoa.The cocoa tree flowers all year round, in two cycles of six months. Thousands of minuscule white (female) and pink (male) flowers adorn stem and branches. No more than forty of the thousands of flowers will eventually develop into cocoa pods.After six months, the cocoa pods are full-grown and are ready to be harvested. There are two harvests per year.

Lets go for harvesting the cocoa fruit

farmers cut the outer peel of the cocoa pods open with long knives to collect the fruit pulp inside. This pulp contains 40 to 50 seeds.

beans are left to ferment for five to seven days. This natural process removes any of the remaining fruit pulp around the beans.

During fermentation, the beans change from gray to brown to purple and develop their aroma. After fermenting, the cocoa beans are spread out and left to dry in the sun for about six days.

From cocoa bean to cocoa liquor

Cocoa beans are cleansed of stones, dirt and sand and dried quickly under heaters. This makes it easier to break the beans and to remove the shell around them.

Cocoa nibs are then roasted, which develops their aroma. In special grinders, nibs are ground to a very fine, liquid mass, the cocoa liquor. This is one of the main ingredients of chocolate.

Cocoa beans grinding(smashing)

From cocoa liquor to chocolate

Depending on the kind of chocolate, different ingredients are used:Dark chocolate: Cocoa liquor + cocoa butter + sugar

Milk chocolate: Cocoa liquor + cocoa butter + sugar + milk powder

White chocolate: Cocoa butter + sugar + milk powder

Lets go for the cocoa conching

conching to molding

Some of the liquid chocolate is molded into blocks, drops or other solid shapes. Liquid chocolate must first be tempered so it can eventually harden.

From molding to cooling

During cooling, chocolate becomes hard and shiny so that it comes out of the molds perfectly shaped and ready for packing.

Putting the designs

Packing

PRODUCTS MADE FROM COCOA CHOCOLATEcocoa chocolate cake

cocoa chocolate candies(bars)

cocoa hot chocolate

Cocoa chocolate cookie

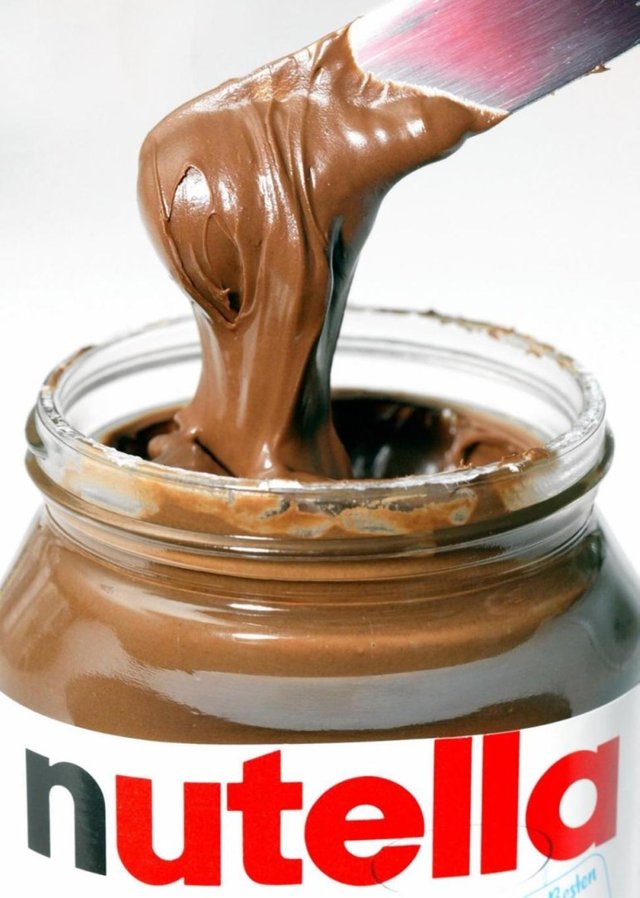

Nutella cocoa and hazelnut spread

Cocoa chocolate ice cream

Cocoa chocolate pie

Cocoa chocolate bread

Chocolate burger

Thats it! If you want to read more please visit:

barry-callebaut.com

Photo sources

drodd.com

janispowers.com

recipegirl.com

cookdiary.net

hersheys.com

Summarized and created by @pakganern

_S_U_P_E_R-P_A_K_G_A_N_E_R_N_

@pakganern... hahaha

Haha

O_O chocolateeeeee

😍

Hello @pakganern, I just stopped by to let you know that I included this post in my favourite reads on my Steemit Ramble today. The post can be found here

Nice thanks

This post has been linked to from another place on Steem.

Learn more about linkback bot v0.3

Upvote if you want the bot to continue posting linkbacks for your posts. Flag if otherwise. Built by @ontofractal