7 years in the making [#2] Rebuilding and restoring a 30 year old BMW - twice.

Welcome back!

First off let me say thank you to all readers of the first part of this story! Glad to see there's an interest in passion projects like this. I guess that means I'll tell this story to the end then. Trust me she's got a grateful eye on all of you as well:

This is my personal blog about my restoration of a 1980s BMW which actually turned out to be two restorations and one engine rebuild. Before you ask the answer is no - that wasn't my plan originally. It's just sometimes things don't turn out as expected.

Some people say you don't buy an E30 you build one. Man I hear that! I'm here to share my story with you and give some insights into what my mechanic and I went through to get this car on the road (again). I'll go through every detail and leave nothing out.

To give you a small impression about what's so special about this particular car in case you're unfamiliar with it, here's a very cool, short and passionate contribution from a fellow fan:

You ready for some more insanity? Alright let's go...

Part 1 deals with the history of the donor car until it dies the first time https://steemit.com/cars/@peterschroeter/7-years-in-the-making-1-rebuilding-and-restoring-a-30-year-old-bmw-twice

Part 2 deals with a short revival, planning and building the engine (head)

Part 3 deals with finishing the engine (block), installation and the final death of the donor

Part 4 goes into disassembly of the donor and the new base, planning the exhaust system and restoring components

Part 5 will go into the engine and drivetrain installation and interior assembly

Part 6 will be devoted to the pain this car gave us because it fought tooth and nail in order to not be put back on the road

Part 7 the final act will go into lessons learned, things left to do, impressions and how it actually drives

Some people might notice that the order has changed and a new part called 'revival' is there. The fact is I literally forgot that this happened until I put together the pictures for this story. If you're in it long and hard enough something like an engine swap can slip your mind. :) Also as this car has been a sort of frame-off restoration including every last screw plus the engine completely rebuilt I couldn't put it all in only 5 parts.

The Revival

So I had this really nice and freshly painted basecar, call it the donor, and a freshly tuned up but totally wrecked original engine:

Quo vadis E30 driver you might ask? I asked myself the same question. Walking away from it at that point was not an option as I could hardly sell a car without an engine even if I wanted to...which I didn't...because the E30 virus has infected me long ago.

So it was a classic fix or replace. Due to the type of damage (ruined cylinder wall) the block would have to be replaced. Now the only thing more rare than a cylinder head in good condition was back then and still is today an engine block in good condition. Even if it was possible to find one it would have meant completely rebuilding the block. The acquisition and related rebuilding costs would easily run into the thousands and I'd still have an old head and in the end the same engine I started out with so that was a no go.

Cheaper but still expensive would have been buying an entire M20B25 2.5L engine so I started looking for one of these:

Some were available, they dictate a price of around 1.500 - 3.000 depending on history, mileage and amount of peripherals that come with it. Thing is if you don't get the chance to check it out while it is still in the donor you're always buying a cat in the bag. Even if it runs after installation there's no way of knowing what condition the parts really have. Given the tendency of the head gasket to give up and create cracks in the cylinder head next to the water sill between cylinders 5 and 6 and a myriad of other things that can go wrong with this late 70s design I decided against it. Looking for and buying an engine still installed was an unbearable hassle in terms of logistics so I was kinda stuck at that point.

Lesson here is clear: If you do decide to buy a complete engine do it only if you get the chance of seeing, hearing and driving it first otherwise it'll always be a potentially expensive gamble.

At that point during another coffee break in the shop we started thinking about what would be the longest lasting, fastest and highest performing solution while recycling as many parts as possible. At that point he said something like "You have a solid 2.5L head, you have a solid 2.5L base car so why don't you just find a good 'ETA block' and build a high compression 2.7L engine?" - I liked that idea.

From the get go I wanted to have an era correct engine in the car. The newer 24 valve R6 BMW engines are smooth as silk and bullet proof, they fit well into the E30 and are cheap to come by but in my mind it ruins the character of the car so that was a no go. Also I didn't want to go to the big iron block 3.0/3.5L units so I decided to pick up his suggestion and go for a classic but optimized 2.7L NA M20 engine rebuild loosely based on something called the Alpina B3 2.7 - I figured it was cheaper than the other options and it sounds nice, plus it will be easier...

Yeah, none of my assumptions turned out to be correct.

If you care to learn more about the inspiration for this car and where it came from I posted a little side story on it here:

https://steemit.com/cars/@peterschroeter/7-years-in-the-making-2-1-the-alpina-story

I Need a Block

So I really was going into a bygone era where tuning of naturally aspirated (NA) engines was very common and enjoyed huge popularity so people weren't afraid to invest a lot (A LOT) into NA tuning for a relatively small power gain as opposed to say a turbo or ECU mapping nowadays.

The pillars of classic NA tuning are:

more displacement

higher compression

optimized intake and exhaust

performance camshaft(s)

adapted ECU mapping (yes the E30s of the late 80s already had BOSCH Motronic Digital Engine Management)

heavy duty components to strengthen the engine

most importantly someone who can put the thing together so it doesn't blow up on first start

and clean parts so the power doesn't get stuck on the sidewalls...

The M20 was the most popular engine in the E30 and offers a variety of options when it comes to getting more performance out of it. The trickiest part was how to go from 2.5L to 2.7L without much hassle? Would be great if BMW themselves had built a 2.7L variant of the M20 right? Luckily they did in something called the 325e. In contrast to the 320i and 325i it wasn't a classic high revving engine, rather it used the added volume for more low end torque and added a throttled cylinder head with a reduced redline at 5000rpm. The result was a fuel savvy, smooth and fast car that ran out of steam at around 3500rpm.

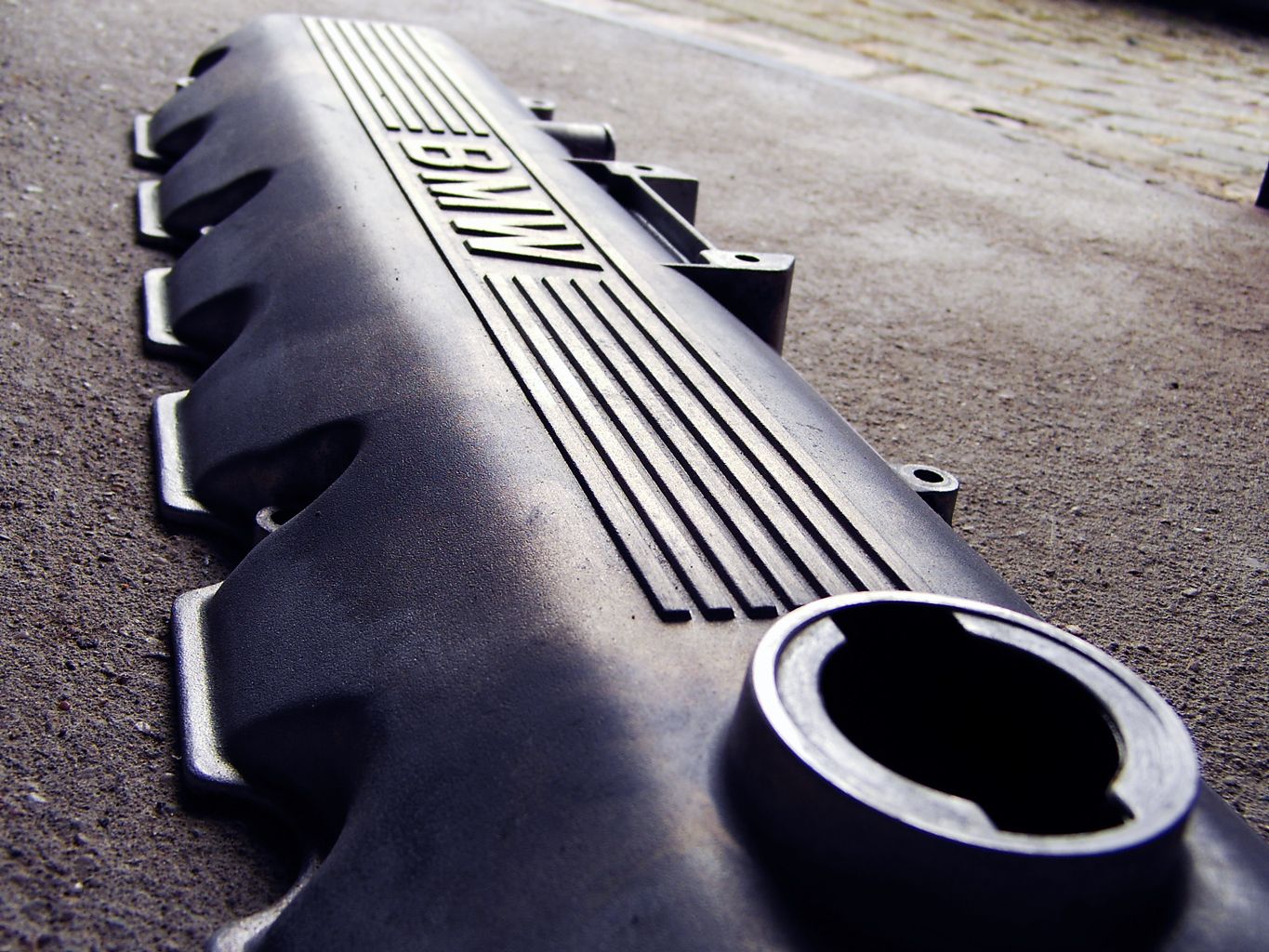

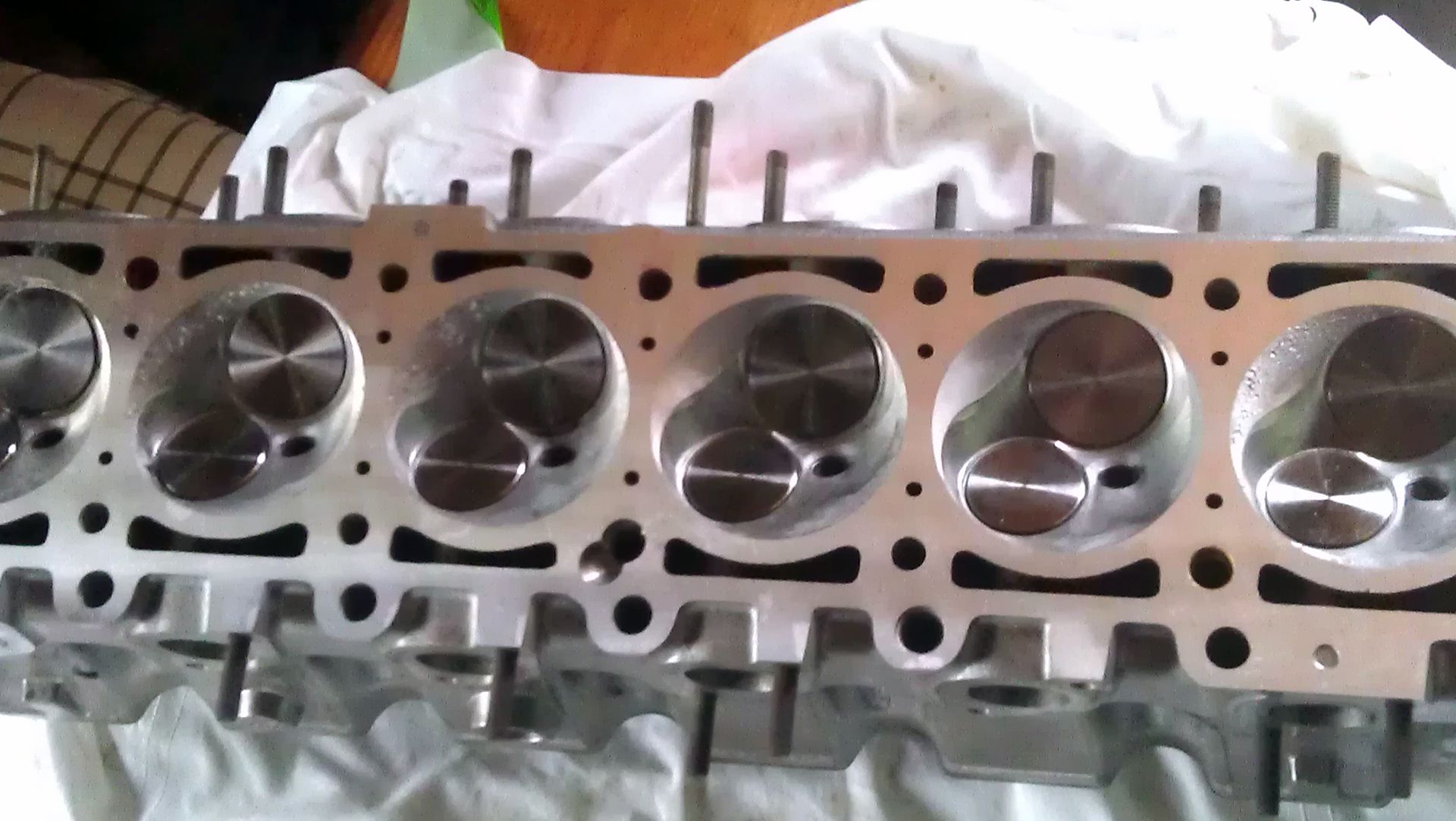

Point is that there's a variant of the 325e that uses the same cylinder head as the 325i. See how the recycling is coming together? This is my old cylinder head after a good cleaning.

Turned out it really was in very good condition.

So I needed a block, a specific block from a car that had only been built for less than 12 months and wasn't very popular. By chance I found someone who was selling a complete 325e engine with transmission and some peripherals for 400 bucks not 150mls from where I lived. It was exactly the version I needed and apparently had 130k mls on the clock.

A quick phone call and negotiation, 300 miles and a back ache later (try to lift a 400lbs engine into a van with two people without an engine crane...don't even ask) I was the happy owner of this weird throttled 'ETA' engine.

Detailed planning and buying the parts would take a while and I needed the car so we decided to go for it and throw the eta engine with its own ECU into my car and see if it runs. First that would show if the engine and therefore the block run fine and second it would buy me some time while still being mobile. Third even if the engine had some weakness it wouldn't be in the car for long anyway.

Lesson with engines you bought that you don't know is simple: make sure you can manually turn the engine at the crankshaft. It should rotate without any harsh sounds or resistance. Drop a lot of WD40 into the cylinders through the spark plug holes. Fill up the oil to maximum. After installation remove the ECU relay so that fuel and ignition are powerless, take the spark plugs out and start the engine. It will not fire but build up oil pressure while not under load. That way you can be sure that oil is everywhere it's needed. You can then reinstall plugs and ECU relay and then...try your luck!

In my case it started right away and ran fine. Total installation time of engine with transmission at that point (after having done it how many times) was 4 hours...yeah we pride ourselves on silly shit like that :).

So in November of 2011, 3 months after the old engine blew up, I drove off in a 325i'e' :)

It was a vastly different driving experience. Huge torque from idle up like a modern diesel, all the while it used less than 7L/100km and was silky smooth with a very particular almost absent sound characteristic. Of course on the top end I missed my good old 2.5 which would keep on pushing even if you put the hammer down at 120mph/180kmh.

So the goal was to get that back and enjoy the performance knowing exactly what's under the hood and being able to push it like a new engine because well, it would be.

I drove the car with the throttled 2.7L for about 10.000km/6.000mls until late summer of 2012. By then I had the engine blueprint in my head and was ready to pull the trigger.

Meeting in the Countryside

This part of the story will dive deep into planning, building and setting up a complete engine from air intake to exhaust tip and everything inbetween. I'll also touch on some basics of naturally aspirated petrol engines and what matters when you aim for maximum performance without compromising daily usability or engine durability over the long haul - which was the goal.

If you're not into the nitty gritty here then we'll see you on the flipside in Part 3 :)

Still here?

So first thing to deal with was finding someone who can actually build the engine and preferably has some experience with the M20. My mechanic referred me to a guy who's been building engines for 30 years and used to build race engines for endurance sport. We went to this farm out in the countryside with a small garage attached to it. When I saw the Denso hat the guy was wearing and listened to him speak for 5 minutes I was sold. He had enough tools in that place to build a f***ng F1 engine let me tell you.

When I told him that I planned to build a 2.7L M20 with all new components he took a good look at me and literally went: "you're the first person in this shop who wants me to build this engine since 1997". Not sure how that made me feel but at least then I knew he's done it before.

He asked me about the head how hot I wanna go with it, I told him Alpina have used a 268 degree camshaft in their engine which was my reference. Since I didn't wanna push it too far I decided to go with a Schrick 272 cam, he nodded approvingly. Valve springs? Also Schrick, slightly tighter than the regulars, my goal was a head that was bullet proof up to 7500rpm. Regular redline is at 6.500 and anything over 7500 is overkill anyway. "You're gonna need new valve stem seals, that's no problem." he said. "What about the valves you want me to prop up your old ones?".

I'm telling you guys in a moment like that you literally feel like you're standing in some garage at Le Mans planning you're next race engine. It was an incredible feeling and for the first time I realized what that sparkle in people's eyes is about when they tell you 'I built it'.

Back to the dimly lit shop way out in the countryside with two guys looking at me with a mix of disbelief and excitement. "Valves will be new Schrick ones all around." I later found out that original valves are perfectly fine and rarely fail but wanted to make sure everything is rock solid. He went on "Rocker arms, planning to take the regulars?". Good question as these parts tend to break which can have grave consequences so I asked if there's an alternative. "Race parts" he said "close to 800EUR for a complete set". Mind you the standards can be had for 200 bucks - all of them. I put it down on my to do list.

## On to the compression... ##

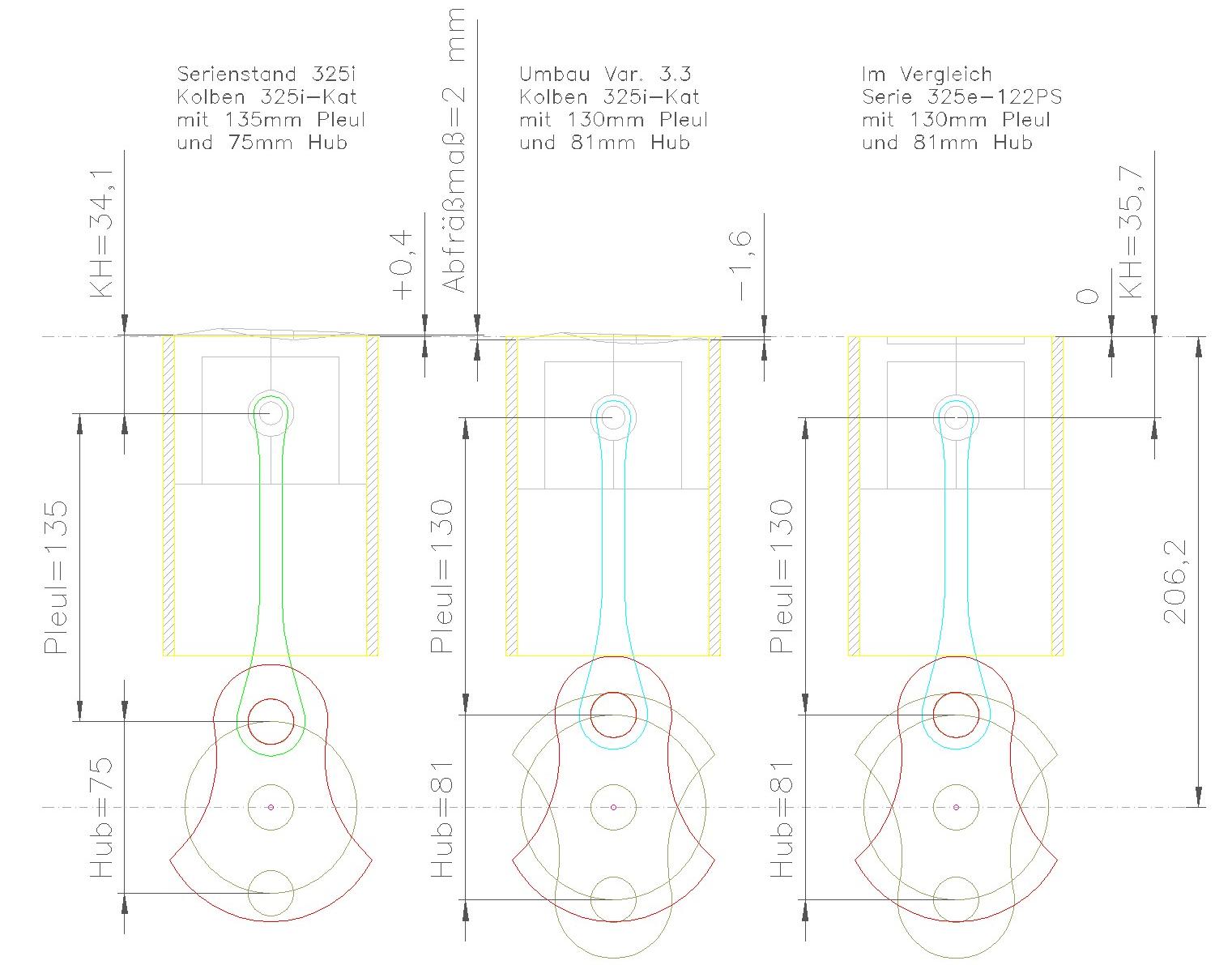

(Picture courtesy of www.e30.de)

See the way you increase the displacement here is by increasing the stroke which is achieved by using the crankshaft and piston rods from the M20B27 eta engine. In order to get to high compression though you must use the pistons from the original 325i engine.

On the left you see the regular 325i with a crankshaft with 75mm stroke and on the right the 'eta' one with 81mm stroke, that's the crankshaft we want. As we've seen before the 325e is a low compression motor so when combining that block with the 325i head and pistons we have to offset the low compression by bringing the chamber closer to the piston. This is achieved by decking the cylinder head i.e. milling off some material.

The problem is that the regular 325i piston skirt collides with the 'eta' crankshaft weights. Alpina have used specially produced MAHLE pistons to solve this problem (thousands of dollars again). Cutting the existing piston skirt on the other hand creates the issue of having to balance the pistons later on - something I wanted to avoid. Early 325i versions without a catalytic converter had pistons that would fit, so called 'catless pistons'. But they're just about as rare as the Alpina ones and equally expensive.

In the end I settled for so called 'weight optimized' late 325i pistons which do fit and are a bit more common. I only had to buy two sets until I found one that wasn't damaged - welcome to the world of hunting for spare engine parts :).

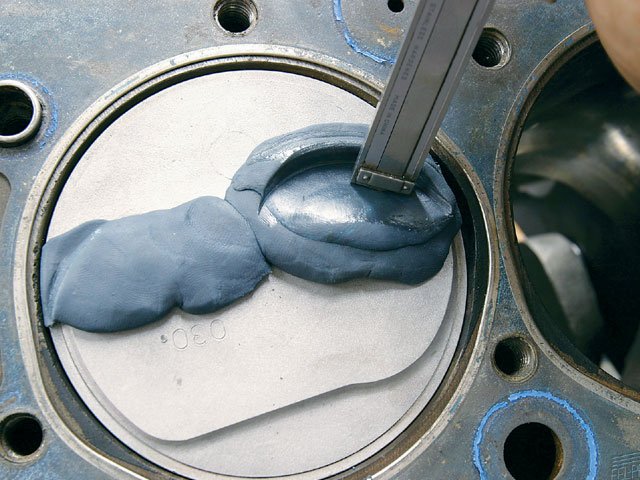

"If you provide the pistons" he went on "I'll put the head and the block together, see how much I have to deck each and mill the valve pockets in the piston to create the necessary crushing gap for high compression." If you just didn't understand a single word of that - neither did I at the time.

He's talking about this:

(Picture courtesy of GrumpysPerformanceGarage)

After decking the block and the head the motor has 2.7L displacement and a compression ratio of close to 10-1 but now the valves will collide with the piston as it moves to the dead center so what you do is measure how much it indents and then mill the valve pockets into the pistons accordingly. The way this is done you can see above.

So we were good to go and all I needed to do was bring him the head, the parts and the block and I'll get back my new engine...or something like that.

"What you're building here this is a beautiful motor, you won't regret it. Can't compare them engines to the planned obsolescence of today..." how right he was.

Headwork

After ordering some beautiful engine parts from Schrick and a wonderful BMW parts store in California called 'Ireland Engineering' I had it all together for the upper part:

Schrick 272deg symmetric camshaft, new valve springs and 12 shiny valves. Valve seats were standard BMW parts.

The solution for the rocker arms came from the Cali guys. Above a nice comparison of a standard (truly terrible quality) part and their offering. Much more refined, strengthened and stable up to 8000rpm - I like! In addition to that they were even cheaper than the regular part and light years away from the 'race grade' parts.

Ireland Engineering adjustable cam-wheel. Because I changed the distance between camshaft and crankshaft by decking the parts this wheel helps to offset that difference by tightening the drivebelt.

In October 2012 the head was ready:

Shortly after all components were installed and it looked beautiful. Excuse the poor quality, didn't have my camera on me at the time:

If you've stuck with me to this point I guess now you're hooked. Join me next time for the mating procedure :).

Thank you for reading, any questions just ask.

Coming up

I think this is the first time I've come across someone covering an E30 in the making (restored) and might I say, A JOB WELL DONE SIR! Very detailed coverage of the journey and don't let me get started on the pictures. Wow, just wow. I'm not too much of a fan of the classic BMW. However, very nice work here. FOLLOWED! Cheers!

Thanks a lot and glad you like it.

Loved it.

I once owned an 85 e30, I loved that car so much.

'85 is a good year. That's a so called pre-pre-facelift. I owned one like that once, 318i with a hilarious chocolate brown interior (including armrests, door panels, carpets, seats, everything in chocolate brown). It was a blast, the older E30s are even lighter than the late ones I think it was 2100lbs/1050kg.

Great post mate!

I have a classic Baja Beetle which I have been tinkering with recently.

Look forward to more followed!

Thanks, that Beetle looks like one fun machine! I'm pretty sure I'd love the sound...

I'll send you a video link through later 👍🏽

I'm still driving my 1991 325i convertible, e30, 5 speed. 180,000 miles. New roof, new exhaust, runs like a top. Very interesting to see the rebuild and what the guts look like.

Wow that sounds very nice! Please keep it and keep driving it.

No worries, when we're done here you'll know that E30 inside out including some spots no E30 owner actually ever wants to see - haaahaaa.

Thanks, I'll keep her as long as she keeps going. We lost my wifes 1987 e30 a few months ago. The automatic transmission blew a gasket on the highway and destroyed it. My mechanic gave it to a friend as a parts car.

Phenomenal work. The old bimmers are the best bimmers. Keep up the good work.

Will do for sure! Thanks for your comment.

Without going down the nostalgia route but yes I'd have to agree they're the best. Back then the Manufacturers were thinking how can we build the best and most reliable car and that they did. Not long after in the early 90s they realized the magic's called leasing/financing and make the cars break down so customers leave more money at the dealer.

Exactly. Planned obsolescence. The bimmers were built like tanks back then. My last e36 had 250k miles. I was racing it, drifting it, it was part daily and I would drive the car from alabama to louisiana for work then drive to texas for the hell of it and visit friends. Just super tough reliable cars. I know a guy that was drifting a e34 535i and turboed the car at about 250k also and didnt take the engine apart until around 300k and that was bc he finally blew the hg when a wastegate stuck and over boosted. these things are built amazingly tough. you cant do that shit these days. I am so glad to see ppl rebuilding and modifying these cars still. Ultimately what killed my e36 was driver error and a wall. I have no doubts when the time comes I will be building another car and it WILL be another BMW.

What an awesome story, I don't know what it is with the E34 being turbo'd but it happens A LOT. They were built like that and they're not anymore and that is just a fact. Look at the E30 it's not a luxury car but it was expensive as hell in it's day, why? Cuz it's built like a tank.

Looking forward to reading about your new project whenever that may be!