All you need to know about How to make a Reflector Telescope !

Making

a telescope is one of the most satisfying and sublime joys you experience. And also is a really hard work,However it would be easier if you start reading and searching about it online.

But this also requires too much time. and to make it easier, here you can START.

So i want to bring in hand all you need to know about how to make a really good telescope.

The first thing you should know about, Is the types of telescopes.

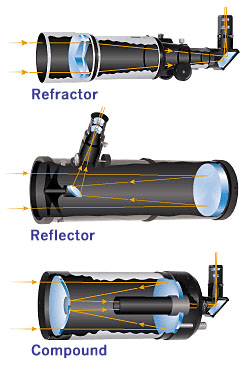

there are three main types of telescopes.

1-Refractor Telescope

2-Reflector Telescope

3- Compound Telescope

working principles of them are similar and simple.

They work on collecting light on a specific small point called eyepiece

Here we will only talking about making the second type of Telescope called Reflector telescope or (Newtonian telescope)

Here we will only talking about making the second type of Telescope called Reflector telescope or (Newtonian telescope)

Because this type is easy to make and works more efficiently

To get started. you will need several components . like..

A flat round glass 6 inches or 8 inches. this sizes are the best to start with , (that would be the primary mirror)

The Goal

Our attempt is to make the mirror focus the light as sharply as possible, We want to make the highest power by start pinpoints in the eyepiece.

the process of doing this is called Grinding.

How Grinding Works

Silicon carbide particles are sharp edged. When pressed and rolled between tool and glass, the particles dig into and

the glass.(The Joy of Mirror Making by Mel Bartels)

Creating can be done by several methods:

The curve is ground into the mirror face using a grinding tool.

The curve is pre-generated for you.

The curve is created by slumping the blank in a kiln over a mold

the method that i'm going to use is the first method The curve is ground into the mirror face using a grinding tool.

Grinding the curve into the mirror face can be done by some ways, the way that i use is Ceramic tiled tool ground against the mirror face.)

Grinding components

first for the Rough Grinding you will need to

-grinding tool

in this video you can learn how to make one

-rough grinding

First milestone is putting a curve into the mirror surface. The depth dictates the mirror's focal length. The curve should be spherical.

-The Wet

you have to add Grit and water between the tool and the mirror. The top piece will be back and forth with pressure. it will make noise - louder is best. it is better to add to much water and doing it fast and hard, After a few minutes the glass builds up with the broken down silicon carbide will stop making noises. and you will need to doing the process again and again, this will be added to the number of the Wets, like the fist time is one Wet and the second is two Wet and so on. and you will be continue until you get the right depth.

for example we will make a 6 inches mirror with the Focal Ratio of 6, then the length of the focused light will be 1 meters long from the primary mirror.

for find the Focal Ratio of your mirror, please take a look of this video

After finding the right Focal Length you will have to go through another process

Fine Grinding

Your efforts of fine grinding are to make the curved mirror face prepare,to be ready for polishing and figuring

The three grit sequence for Fine Grinding:

220 silicon carbide grit

500 silicon carbide grit

9 micron aluminum oxide (MicroGrit WCA-9T or similar)

The next step is called

-Polishing

Polishing will be so accurate. it is a hard work and breath taking.

The goal of polishing is simple: polish all the tiny holes that remain from fine grinding, ending with a smooth spherical mirror surface ready to mirror coating.

take a look of this

Now your mirror is ready to set on your telescope base.

for making a telescope base you can watch this videos

part 2

part 3