3 Important Tips for Energy-Efficient Motion Control

Energy-Efficient Motion Control

Making small but significant changes can drastically reduce energy consumption in motion-control systems.

With vitality effectiveness benchmarks getting to be plainly stricter, makers expect to be all the more ecologically inviting by decreasing carbon outflows over the industrial facility work space yet additionally don't have any desire to give up productivity and execution to do as such. Makers are acquainting more computerized frameworks with the manufacturing plant floor to streamline the creation line and effectively convey items to clients. In any case, as the industrial facility builds its robotized forms, it requires more vitality to finish generation.

The following key technology areas can help manufacturers achieve efficiency in their automated devices and maintain a low operating cost.

1. Variable Speed Drives

Installing variable speed drives can help regulate the amount of power your motor drives are using.

Most mechanical machines work utilizing engines. Around 66% of vitality utilization in industry is credited to these parts. When checking gear, producers may find that the engines are working quicker than required and may even be running when the machine is not being used.

Introducing a variable speed drive (VSD) is the most ideal approach to lessen engine speed to line up with generation. A VSD is an electronic gadget used to manage the speed of enlistment engines. Electric engines expend roughly 25% of the world's power for mechanical and customer applications. This gear directs speed and power of an electric engine to change the speed in view of that of the mechanical production system. VSDs enable administrators to control the engine at any charge speed. They give vitality funds and control capacities while broadening the life of gear.

2. Eco Obsolete Technology

Eco Obsolete Technology are products that are no longer supported by original equipment manufacturers but still comply with energy standards. These parts help ease the burden on manufacturers to buy new equipment and provide a cost savings.

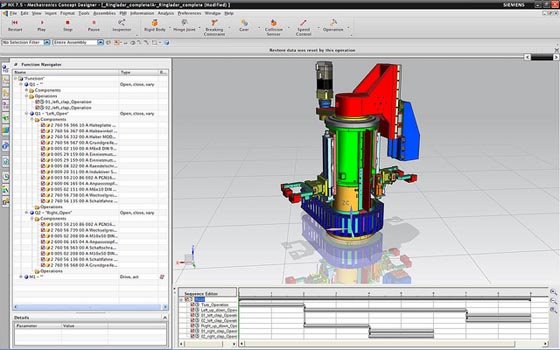

3. Software

The Intera 5 Software from Rethink Robotics is an example of robotic software that should be kept updated to ensure the robot is operating with the latest greatest updates. By using the latest version of the software, the user can assure that the robot is behaving as desired and efficiently.

Nice post upvoted frnd....

Thanks

interesting friend thanks for sharing it @ nanowins77

Thanks.

Congratulations @tanvirahmedshaon! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOPOhh all time Yahi 😉

nice Technology

Hmm that's right

great post.

Thanks

GOOD

good Technology.. upvoted

Thanks

Keep posting on great post.. keep steem on

Love ur posts. Keep it up!!