Very clever engineering - A 3D printed desktop metal distillery.

3D Printing? So what - It's been around for a long time.

Yes it has. Most of you reading this has already heard of it, some of you have seen one and a few actually has one in their home or at work. We are generally speaking of the cheap plastic extruder kind, which is very dominating by figures on the market.

But there are another kind which is not yet commonplace, and that is the metal 3D printer. The large manufacturers like Boing, GE and the like has used them for many years.

They will never be in every home. They are extremely expensive, the nano metallic particles that gets fused together to a solid is forcing you to wear a Hazmat suit with filtered air intake. If you inhale the dust you die...(That might be an overstatement but you get the picture) Another downside is the support structures.

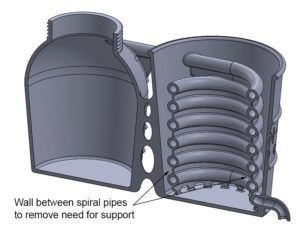

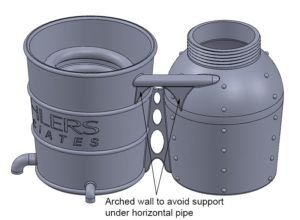

Here you can see support structures holding upp parts of the model that has overhang. What is not generally known is that you must use support anyway, because of the very high energy created by the laser melting the metal powder. We all know that metal expands and shrinks according to the surrounding temperature. During printing tremendous forces acts on the printed part, making it want to warp. So the support acts also like a firm support to the ground, preventing warping, and it will also dissipate heat away from the part. So even if you are printing pieces in a box of metallic powder, that power is not strong enough to prevent warping, like in plastic powder printing (SLS). Hence you need support structures.

The painful work

When a part is printed, and it comes out of the printer looking something like the part above, all the support pins has to be removed. This is a piece of cake when they are made of plastic. You use your fingers or a pair of pliers. A little sanding and you are done. Not so when the stuff is made of metal. It demands a whole new level of dedication to clean a part after printing.

In this article Olaf is talking about post processing literally with bleeding fingers and that 70% of the total cost of a 3d printed metal part can be associated to the slow and tedious post processing. So if you can reduce this, the parts will be way more affordable.

A new way of thinking

Olaf Diegel, professor of product development at Lunds University in Sweden, Also known for his famous 3D printed guitars in ODD Guitars, made this distillery model as a design experiment. The goal was to minimize post processing by clever design before it is even printed.

If you create features in your design that are to be there after it is finished and that can act as support while printing you do not need any support that has to be removed later. Here is placed a wall between the coils and this wall hols the next turn up so the complete coil is supported by its own. It does not hinder the function of the coil.

A very exclusive give away for someone special.

This device is very beautiful, not very useful, but extremely cleverly designed. It shows in an excellent way how you can add time and effort before you design something and make that up as a profit of time in the reduced post processing.

This device is very beautiful, not very useful, but extremely cleverly designed. It shows in an excellent way how you can add time and effort before you design something and make that up as a profit of time in the reduced post processing.

3D printing is here to stay

This technology is exploding in development right now. You can build stuff in a 3D printer that is not possible with conventional methods. Try building this distillery apparatus in one piece as it is shown here.... not possible.

Main areas of interest:

- Parts consolidation

- Complex shapes

- internal channels for cooling/heating

Read the story here

Please do me a favor. I have referenced an article and pulled some information from that, adding my own thoughts about it. To do Olafs work justice, please read the source here:

https://3dprint.com/179977/desktop-distillery/

Did you find this interesting? Upvote

Do you want more? Follow me.

Do you want others to see this? Resteem it.

Thanx mate.

I also would love to have a metal 3d printer. But its as big as a refrigerator :-D. But the good thing is, if your prints failed, you can reuse it again. So nothing wasted. I wish we could do that with plastic too. I wasted meters of pink filament this week.....

Failed prints are a pain in the ass. Advancements in technology will probably lessen that in the years to come. But for now the best advice is to learn your machine to your best ability. Nothing beats experience 😁