Move Aside Skywalker, the Real Vaders are Here with Liquid Metal 3D Printing

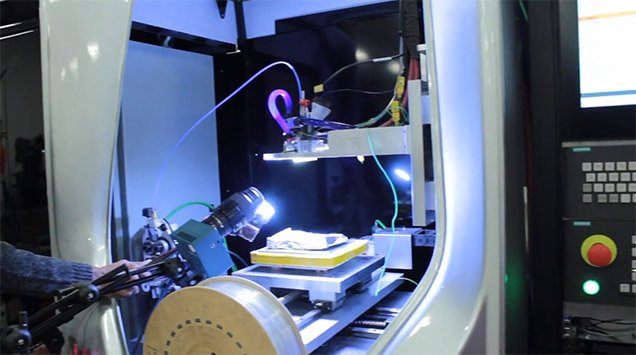

Scott and Zack Vader are a father and son team who created Vader Systems and a liquid metal 3-D printing machine.

Anakin and Luke Skywalker failed as a father and son team, while these two succeed, and they are real Vaders!

source

This is a significant transformation in manufacturing of metal parts. The metal "printers" that currently exist cut the metal by melting it down with a laser or electron beam.

source

Zack is the CTO, his father Scott the CEO and mother Pat a controller of the machinery. The family business might be booming soon, as one automotive parts maker is interested in buying 50 of these machines.

source

Zach was a former student at the University of Buffalo (UB) when he had a breakthrough at the age of 19 with his dad working in their basement. He and his father were part of the START-UP NY program and has since worked closely with the UB engineering faculty and students and has also received grants to transform their idea into an industry.

Vader Systems now have three faculty advisors and have hired three mechanical engineering graduates from UB.

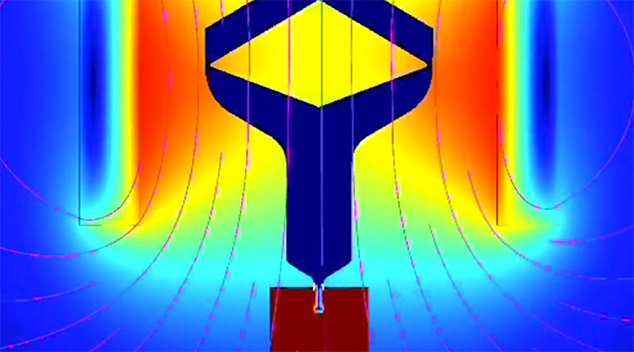

The idea started for Zach when he wanted 3-D printed parts for a micro turbine generator, but no company would print the parts you needed. He tried tackling the issue himself and his breakthrough happened when he thought of regulating molten metal with a pulsed magnetic field.

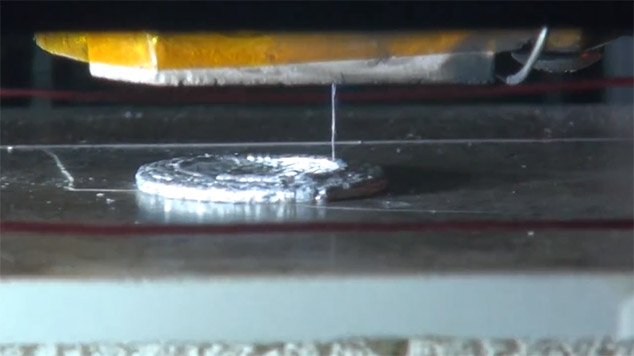

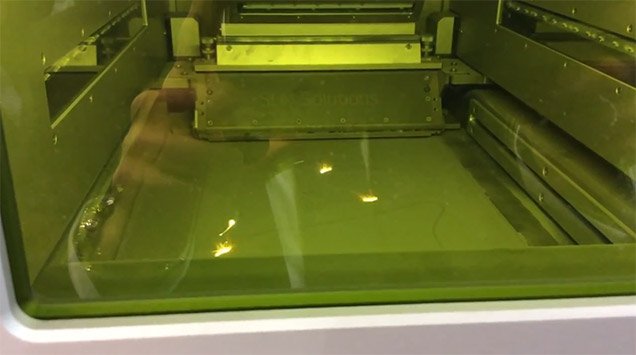

The Vader machine can currently print aluminum by heating it to 750°C. They use aluminum wire that is fed into the machine and melted.

source

The liquefied metal passes through a ceramic tube forming into injection chamber with a submillimeter orifice that allows drops of aluminum to be pushed out with electromagnetic pulses.

source

The process is akin to an inkjet printer except with magnetohydrodynamics, which is the manipulation of conductive fluids using a magnetic field. Printing is done with very fine droplets of metal.

An electrically pulsed magnetic field is timed to release one droplet 50 times per second.

source

There are plans to modify the device with better nozzles to increase speed printing, and eventually make a machine that can melt steel at 1,400°C.

Ciprian N. Ionita, PhD, a research assistant professor in the Biomedical Engineering Department working at UB, thinks this technology will be in every hospital ready to dish out custom parts for constructing or replacing surgical devices on the fly, when needed. This will extend the lifetime of products greatly, and possibly make it easier for anyone to replace a damaged mechanical part. Being able to print out custom knee and hip replacements is also being envisioned.

source

The current method of cutting metal as a printing process requires the use of a metal powder which is a contaminant that is difficult to clean up and is toxic to the human body at certain levels. The Vader System technology is also much much cheaper. Chi Zhou, one of the advisors, says this tech will likely develop and help with the existing metal printing, but in 10 years it will probably dominate since it's better quality and cheaper printing.

One of the great features of this manufacturing process, is that complex parts are just as cheap to make a simple parts. "Complexity doesn't add cost", says Zack. This is the opposite of traditional manufacturing which should propel this company into great success.

source

The Vaders plan to expand into an assembly manufacturing facility. They hope more of the automotive industry gets interested in making hollow and honeycomb structures, which are stronger and cheaper than the solid metal that is currently used.

"It's an idea that's time has come", said Scott in closing the video below:

3-D printing liquid metal with Vader Systems

References:

If you appreciate and value the content, please consider:

@krnel

2017-01-13, 10:02am

There is always pros and cons to this type of thing.

One of the great challenges of space travel has been identified in regards to 3d printing. If someone can make one of these 3d printers work in zero g, then it would extend the ability of mankind to push further into the Universe as they could repair and make replacement parts on the ship, which has always been one of the most limiting factors of space travel. Advancement of 3d printing technology will allow mankind to reach new heights and achieve things once thought impossible.

The bad news, I think the future of 3d printing will cause what is defined as a "mode of production change" as theorized by Karl Marx in the Communist Manifesto, and will result in a society that has so much surplus due to the new production changes that no one will have to work. This will cause what is described in the documentary "obsolete" to take place. It is a scary and worrisome future due to these types of technologies in my opinion.

Sounds like paradise to me. I can imagine printing my own house or car. And without debt!

Cool stuff, any idea how much one of those Vader's cost?

No idea ;)

I wonder if this can be used in the manufacture of MEMs devices?

I don't it has a wide range of uses yet. I'm sure the regular method still has its requirements in many areas.

Upvoted!