Floorplanner & 3D Printing

Last April I asked my wife-to-be to marry me. Being a bit of a nerd I thought it’d be cool to give her a 3D printed engagement ring. One of a kind, a ring specially designed and manufactured for this romantic occasion. However, I had no idea how this ring should look like, so I hit the web searching for rings on Shapeways and Thingiverse. The ring had to be complex and made of some crazy material to show that it could have only been made with 3D printing.

Looking at all those rings made me wonder if a 3D printed ring was such a great idea after all. Barbara probably wouldn’t care much about it - actually - she would probably not like it at all. I decided to ditch the whole idea, do a 180 degree turn and go for the classic combination of gold and diamond. Marcel Vermeulen made a fine piece!

And Barbara said yes.

Floorplanner & 3D printing - Take one

Exactly six years ago we launched a new product at Floorplanner: a 3D printed floor plan. For a mere $129 you would be the owner of a real 3D model of your new home, made of a stone like material in a size of about 15 x 15cm. Next to the standard 2D and 3D floor plan images, this was a new and unique way to present and experience real estate. It was 2010 and 3D printing was all the hype. We didn’t do the 3D printing ourselves, we partnered with a Belgium company called Materialise (one of the guys now runs his own 3D printing startup Twikit). We provided them with a digital 3D model of the floor plan and they did the actual 3D printing.

Right from the start we got quite a bit of interest from real estate professionals, but we quickly learned that the real world is very different from the digital world. In our world - the digital world of real estate and interior visualizations - it’s easy to fix small errors. Just open a floor plan in the editor, move a wall or a piece of furniture, save the plan and re-export the images. Done. Not so in the real world.

There was a lot of manual handling involved before a client finally got her 3D model. When we got an order we exported the digital 3D model of the floor plan and sent this to Materialise. They would import it into their software to check and fix things that couldn’t be printed - like very thin walls or small furniture pieces - and then they would print it. After the print they had to do more manual work like polishing the model to make the surfaces smooth. When finished, they would send it to the client.

All these steps and manual work made it quite an expensive operation. The $129 might look a bit high, but it was actually the cost price of a 3D model. We thought that if we would sell more, the prices would go down and we’d be able to make a small profit. However, that’s only right in a world without errors.

We sent our first client the wrong 3D model. The second 3D model we sent her had a few issues, and the third 3D model was late for her presentation because the production facility was closed due to a holiday. After only five clients we were cured, this was not for us. It simply took us too much time and effort without a profit margin in sight. We stopped offering real 3D models and returned to a complete digital strategy.

The promise of 3D printing took an unexpected turn

Now six years later, the hype is about self-driving cars, clean energy, virtual and augmented reality, drones, artificial intelligence, cryptocurrencies and blockchains… but not about 3D printing anymore. It’s not that nothing has happened in the world of 3D printing, it’s that the promise of 3D printing turned out different than anticipated. Instead of doing 3D printing at home, it’s probably your home that will be 3D printed.

3D printing seems to be much more useful for manufacturers (industrial printing) than for consumers (desktop printing). Manufacturers have been using 3D printing for years already to create fast prototypes of new ideas, but lately they are switching more and more of their production to 3D printing.

First of all, there is no need for keeping a large inventory anymore. Rather than keeping a wide variety of parts in several colors and finishes, part makers - especially in the auto, truck and aircraft industries - only have to maintain the digital files and print on demand. What is more interesting is that designers can now design completely new parts that can only be 3D printed. For example, General Electric - who just bought two industrial 3D printing companies for $1.4bn - replaced jet engine fuel nozzles made from 18 smaller parts with a single, lighter, stronger, longer lasting, and cheaper 3D printed part.

If 3D printers can be installed anywhere in the world and only print on demand, why would manufacturers put them on the other side of the world and ship the results back here, with huge transportations costs and waiting times? That’s why there is trend going on called ‘on-shoring’, localizing production again. Reducing transportation costs, CO2 output and time to consumer.

3D printing is not only used by manufacturers of auto, trucks and aircraft parts. You can also 3D print personalized dental crowns and tooth bridges, or bones, or even personalized Adidas running shoe.

Floorplanner & 3D printing - Take two

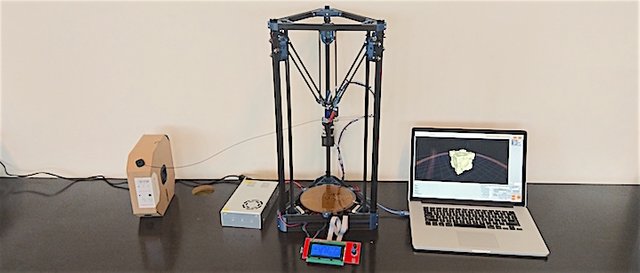

This summer we bought a 3D printer for the office, a DIY kit from the Dutch startup Build a 3D Printer. No, we don’t have any intentions to start offering real 3D models of floor plans again. And we don’t believe that people will use Floorplanner to print their own houses (yet). It’s mainly for fun and to be able to do a few experiments with it.

Besides printing new buildings, how could 3D printing be useful in the real estate and interior decoration businesses? I think that you have to look at the things that are always custom in and around the house. In existing buildings, new window and door frames are always tailor made, let’s print them. Maybe it makes sense to start printing staircases, skylights / dormers, wardrobes, kitchens and even garden fences (yes, looking at you Nico!). It also sounds logical that furniture manufacturers would use 3D printing. If not to make their offerings more customisable, then at least to be able to deliver faster. I don’t want to wait 12 weeks on a couch.

At Floorplanner we are happy in our digital world. We won’t do any professional 3D printing ourselves, but it is important to us that our 3D data is capable of being 3D printed. And we continue to focus on real estate and interior visualizations. If manufacturers give people the tools to create custom furniture, then we will happily show them how their creations will look in their homes.

Great Post. I had already planned on 3d printing floor layout of my own house, to show of planned modifications to my less spatially aware relatives. On paper they cant visualize it.

Wow! It's really amazing!

I like it.

Thanks!

Are you the original author of this: http://gertjanvanderwel.com/blog/floorplanner-3d-printing.html

If so you might want to verify yourself to confirm you are the original author to avoid possible confusion... and issues.

I am ;) How do I verify myself? I just joined.

The easiest way would be to just post something about you being on Steemit and link to your profile here on your blog for example. It would be good to also link to your verification post when you are reposing content from your blog here in order to ensure you are the original author.