HAZARDS AND RISK

Introduction

When a person deals with the safety and health risks at work, he talks about the probability of injury and his impact on the hazardous worker at his place of work. The probability is the measurement of frequency of accidents. Because of the probability of accident and the impact of accidents can be controlled, then risks can be managed so that they can be minimized and accepted.

There are three basic but important words that are often used in occupational safety and health risk management. The words are hazards, risks and dangers.

Definition

Hazard

Hazard is anything alone or interceding with one another to be harmful. This harm varies from fatigue to death rather than minor injuries. "Occupational Safety and Health Assessment Series 18002" (OHSAS 18002) and ISO / IEC Guide 51: 1999 defines hazards as a source or condition that has the potential to cause harm in the context of injuries and illnesses to humans, property damage, workplace environmental damages, or the combination. Chemicals, radiation, electricity, biohazard, unsafe work systems are some of the hazard examples.

Risk

According to OHSAS 18002, risk is a combination of possibilities and the consequences of a hazardous event occurring. Risk can also be defined as a combination of the probability factors of occurrence of the unfortunate events, exposure and impact of the accident. The probability here means the cans of the accident happen.

Danger

The hazard illustrates the relative exposure of a person to the hazard. This word is more of a word that describes or exposes a situation of risk. For example, a person who is always vulnerable to hazard is more dangerous than a person who is not exposed to hazard.

Relationships are in line with hazards, risks and hazards

Relationships between hazards, risks and hazards are more easily explained using examples. Concentrated hydrochloric acid is a chemical hazard because of its corrosive intrinsic properties that can potentially cause harm to human health and damage to some substances. The risk of splashing acid to the face of the employee is high for those who do not wear face shield compared to those who wear it. Danger if it puffs acids with hydrochloric by mouth.

Ergonomic hazards

SAFETY AND HEALTH RISK MANAGEMENT SYSTEMS

Occupational safety and health risk management systems are concerned with managing risks associated with their employees, activities and working environment. Because there are too many employees, activities and various working environments and a combination of all three, then management can only be made through a management system. Occupational safety and health risks involve four major stages that occur consecutively and provide input to ensure effective management. The risk management system starts with:

a) Identify hazards

b) Assess risk

c) Controlling risks

d) Measuring achievements

The first stage involves the identification of hazards at work or in the task. Hazard identified has assessed its risks quantitatively or qualitatively and determined whether the risk is acceptable, within acceptance or otherwise. The next decision is to take measures to control the risks at a good level, management achievements need to be monitored and measured. Feedback received from achievement measurements is applied at all levels of the management system to make any change of control more relevant.

Biological hazard

HAZARD TYPES

Based on the definition of hazard (above) we will find a variety of hazards that can be found in a task or workplace. If we are asked to list these hazards, we will usually focus on what we see, real and cause death or injury only. Since there are too many hazards, here we will touch only the following:

(i) physical hazard

(ii) chemical hazard

(iii) biological hazard

(iv) ergonomic hazards

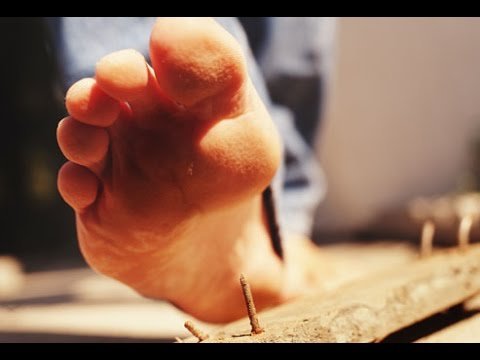

(i) Physical hazard.

Physical hazards are hazardous hazards arising from machines and equipment used. A machine and equipment is considered to be dangerous if:

a) Designed unsafe and imperfect

b) Not well maintained

c) Run by unskilled workers

d) Used not for real work

e) Used in varying circumstances

f) Changed / altered illegally

g) Employees are unprepared or not focused on using them.

(ii) Chemical Hazard

Among the reported industrial accidents were injuries caused by touch and sneezing of chemicals. Chemicals used in factories are harmful and can cause injury if exposed to unprotected. Chemicals such as acids, alkali, gases, solvents, cement, synthetic rubber, glass fibers and adhesives are hazardous materials and should be taken with security measures when handling them.

For some individuals, natural dust and natural petroleum dust can cause skin reactions. Among its effects is the skin will burn, blister, burn and will leave a scar effect. Other areas that are susceptible to chemicals are eyes, nose, throat and upper respiratory tract. Chemical effects are dependent on the pH value, concentration, exposure time and the nature of the reaction of a chemical.

iii) Biological Hazards

Workers involved with biological specimen analysis will usually be exposed to disease infections. The danger level of a particular biological specimen varies according to:

a) the nature and concentration of disease agents

b) entry of disease agent into the body

c) exposed employee resilience

The entrance to the limb is:

a) absorption, occurs through wounds and scratches on the skin, absorbs through

skin or eyes, contact with contaminated hands or appliances

b) continuous inoculation occurs with broken glass tools, needles and others where

Infectious agents can go directly into the blood.

c) Swallowing by mouth can occur by smoking, eating, biting

to nail and eat without washing hands

d) The formation of aerosols, as a result of various laboratory procedures such as spills,

flushing, shaking, homogenizing, burning and splashing.

iv) Ergonomic hazard

Ergonomic hazards are related to human mismatches with their working environment. It is often associated with errors or weaknesses in engineering design and work processes that meet the needs of human physiology and psychology. For example typing jobs in good condition are not ergonomically proven to result in 'Tunnel Carpel Syndrome' and back pain.

Physical hazard

ABOUT HAZARD

Before hazard can be managed it must be identified earlier. The sooner the hazard is identified, the easier and less expensive it is to manage it. While hazards may be identified or originally identified as a result of unconscious or changes may arise into materials, systems and designs after use or implementation.

Process and methods of identifying hazards at work

A process that helps identify as many hazards as possible is by using the hazard identification process used in hazard analysis. In hazard analysis, the hazard identification process begins by defining the system that you want to study and define and understand the physical characteristics and functions of the system. There are various methods that can be used to identify hazards. Generally, the hazard identification method involves a combination of self-observation, referring to reference documents, using sensors and measuring equipment, information from reports, feedback from employees and so on.

Observations and References

An experienced and experienced worker in the systems, processes and work procedures carried out through observations and further referring to the acts, rules of the guidelines, codes of practice, standards, data and so on may identify the hazards found in such systems, processes and procedures. . Non-referral observation is difficult to identify a common and routine hazard done at work.

Use of special equipment

There is a hazard that has no smell, appearance, ears or touch. Thus the human senses are unable to detect the hazard. This hazard requires special equipment to detect and measure the hazard level. For example microwaves, ultra-ray are only identified using radiation dosimeters.

Complaint / report / suggestion

A manager is usually tasked with managing extensive work activities and processes and sometimes their general scope. This situation may make it difficult for them to identify all hazards associated with each work process in their control. New hazards can also arise as a result of structural changes, processes and work systems and machines. This situation makes a manager need the help of workers under it to identify the hazard.

Chemical hazard

KEY HAZARDS

There are two main causes of hazard:

a) Working conditions:

i) space that is not easy and comfortable to move

ii) unable to create a free rotation in the work area.

iii) uneven and slippery floors

iv) no proper storage material and equipment

v) imperfect lighting and ventilation

b) Employee conduct:

i) do not work properly, perfectly, safely and appropriately

health

ii) do not ensure that the tools, machines and materials are safe and stored with

Congratulations

iii) does not ensure the way to store, lift or work with harmful substances

safely and adversely affects your health

iv) not according to correct information, instructions and training

v) do not discuss with employers

vi) does not make workplace inspection

Thanks..

This post has been curated by TeamMalaysia Community :-

To support the growth of TeamMalaysia Follow our upvotes by using steemauto.com and follow trail of @myach

Vote TeamMalaysia witness bitrocker2020 using this link vote for witness

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by rombituon from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.