Pumps and Pumping Stations

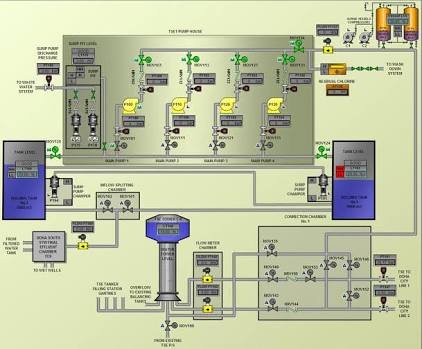

Scada pumping station, source :wikimedia commons

Pumps are hydraulic machines for transformation of electric to hydraulic power. Applications of pumps include abstraction of water from surface or groundwater sources, boosting of water from low to high service areas and lifting of sewage when the treatment plant is above the service areas.

Now let's look at the various types of pumps.

Types of Pumps

There are three major types of pumps which are reciprocating pumps, rotary and rotodynamic pumps. Others are solar pumps, photovoltaic pumps, solar thermal energy pumps and so on.Reciprocating pump discharges a definite quantity of fluid irrespective of the head pumped against. Some versions of it consist of a piston which moves to and from a cylinder. Water is sucked in on one stroke and forced up the delivery pipe on the next stroke. Hence, discharge is intermittent. Reciprocating pumps are straight forward to install, have low rate of wear, simple and can be serviced easily. However, the pumping heads collect grits due to dust in the dry season.

Rotary pumps discharges a definite quantity of fluid irrespective of the head pumped against. Intermeshing rotors or gears of operating within minimum clearance generate pressure and the liquid is impelled around within a closed casing. The discharge is usually uniform.

In rotodynamic pump, velocity is impacted to the water by a rotating element (impeller) which generates pressure. Centrifugal pumps are the most common of this type. Simplicity, low capital and maintenance cost, ability to generate uniform non-pulsating flow, quite operation and no risk of overloading are some of the advantages of centrifugal pumps. However, they initially required priming (the process of evacuation of air in the suction pipe and pump and replacement with water) . Water enters at the centre of the impeller, is collected by the backward-turned vanes, and then forced radially outwards. This action increases the velocity and pressure energy.

Other types of rotodynamic pumps are the multi-stage pumps which consists of several impellers mounted in series (stages) and in each, pressure energy is built up and water is guilded into the next impeller; the mixed flow pumps which lie between axial and centrifugal pumps and the axial flow pumps where the impeller is of the open type without discs and rotational component is imparted as the water enters axially.

Solar pumps demand for energy coupled with the need to mitigate environmental degradation caused by the use of fossil fuels have resulted in accelerated applications of renewable energy sources such as solar energy. One vital area of application of solar energy is in water pumping for ruler water supply and irrigation.

Pumps also could be designed to operate on the sun's light (photovoltaic pumps) or the sun's heat (solar thermal energy pumps)

In photovoltaic pumps, the SEI-250 consists of three major components which are a photovoltaic array that produces DC electricity, a maximum power controller (MPC) that serves as an electronic control, and a high -efficiency pump set. The photovoltaic pumps are more expensive than the solar thermal energy pumps.

In the solar thermal energy pumps, heat is converted from the sun in a panel of about (0.1512m) to energy through solar collectors. These collectors heat a fluid medium that activates a "heart" on top of the pane. The heart is connected to the pump in the water source like (river, canal, well and so on).

The solar pumps are user friendly and durable. Their installation, operation and maintenance are simple.

Application of Pumps

The rotodynamic pumps low and has different flow type like the radial flow type for example (high lift pump), axial flow type and mixed flow type. When the discharge is low, the head is high (>30), when the discharge is high, the head is low (up to 15m) and when the discharge is medium or average the head is about 25m. The rotodynamic pumps are applied for pumping water and sewage, it has higher efficiency in clean water. Sewage pumps are slow in speed, capable of disintegrating solids. Axial flow type usually have problem of overloading the motor.

Reciprocating pumps for example the diaphragm pumps, discharge low(>91/s) with head also low. It is applied to a very vicious fliud pumping, well and borehole pumping. The leakages are unavoidable and inefficient.

Helical rotor pump discharge low with low head and it is used for sewage or liquids with suspended matter, Pumping borehole pump for water supply.

Air-lift pump discharge low with low head and it is applied in ground water recovery from wells with large quantities of sand and silt. And so on.

Pumping Stations

We must have heard of pumping stations, one would ask, what does it mean?

Simply put, pumping stations are facilities with equipments where fluids or liquids are pumped from a particular place to another. Which is used for a lot of purposes like water supply, or gasoline supply or any other liquid. As well as the removal of sewage to the site for processing.

There are different types of pumping stations but then i will be talking about dry well pumping station and submersible pumping station. Which is often used for sewage pumping.

Dry well pumping station is located in a dry chamber and draws from the adjacent wet sump through a suction pipe. The pump is usually vertical and connected to an electrical motor mounted at the ground level to protect the pump motor and electrical switch gear. The mechanical and electrical equipment in this type of station are easy to inspect and service.

Submersible pump station is applied to pumping small foul sewage. The pump is placed in a single wet dump below ground level. The presence of a guide rail and low level quick release coupling system allow the pump to be easily fixed or dismantled. Submersible type cable supplies power to the pump from a control panel. The control panel is located at the ground level and mounted in a weather proof enclosure constructed with appropriate building materials.

Operations and Maintenance

Generally, pump controls are either automatic or manual and in most smaller settings the manual controls function properly. Manual pumps are operated by experience operators who knows when to start pumping and to end pumping with cognizant of the tank gauge. while in automatic controls, the pump is timed by pressure as to know when the water level in the tank or reservoir is high and low. If it is low the pump on button will activate once the water level in the tank is high it will deactivate (stop pumping). Pumps need lubrication for proper maintenance. But more importantly, it should tally with the specifications of the manufacturer.

Conclusion

Selection of appropriate pumps for certain applications are done by experts. Making the right choice will require determination of some specifications such as brake horse power, shaft speed, head, capacity and efficiency.

Knowledge of suction conditions, discharge conditions, service conditions and position when installed are also important.

The most commonly used sources of power for pumps are gasoline or diesel engines or electric power.

The essence of pumping stations are to pump water from a water source like river, also raise water from a deep well and send it to a raised tank or distribution systems.

Reference

[1] Design of pumping stations

[2] pumping station -wikipedia

[3] Knowledge Base

[4] pump station -sswm

[5] Flooded suction

.png)

.jpeg)

Are pumps utilized in irrigation ?

What kind would you recommend?

Yes they are. I will recommend either submersible pump or centrifugal pump. However it depends on the amount of water needed for irrigation in the farm. For lighter irrigation a plain submersible pump is recommended.

Thanks for the feedback @florae

Alright

Thanks for sharing

Thanks for shedding some light to this topic.

Welcome

Pumps can be referred to as

Headright?Fluid mechanics memory back in school. No too good with it but it always worth reading

I never knew pumps has types. This post is really all encompassing and would make a very rich working document for apprenticeship.

My visit to this place not in vain. Thanks boss

@eurogee of @euronation community

yes boss @eurogee .

Thanks for the feedback.

Pumping stations also contain safety equipment and house on-staff safety personnel to overcome any problems along the pipeline route. Nice read👍

Yes they do for the purpose of accidents in station.

Thanks for the feedback.

You're welcome sir

Pumps are the heart of any process industry. You did justice to this one sir!

Thanks for the feedback.

You are welcome.