The Versatile Aerogel, a Special Gel That Has Its Liquid Replaced by Air

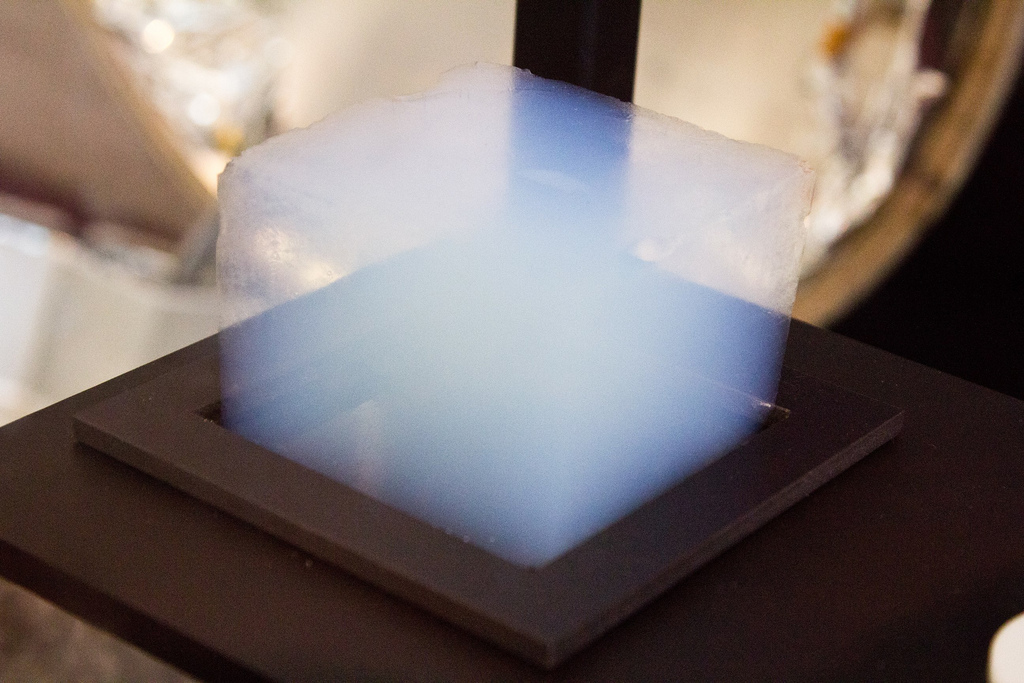

When you casually glance at the blue-coloured, highly porous solid material known as aerogel, one may mistake it for a 3-D hologram.

[Flickr Jon Collier CC BY-SA 2.0]Source: An Aerogel

Its blue colour is from the Rayleigh scattering of light. The same phenomenon that makes the sky appear blue.

Welcome to the world of aerogel, the award-winning material with lots of future and present application.

Sometimes the amazing material is referred to as the frozen smoke. It is the world's lightest solid that currently holds a Guinness Book of record of the least dense solid material in 2013. The density is just 0.16 mg/cm3. Surprisingly, 1 gram of the aerogel could theoretically stretch to cover a football field since it has a specific surface area range of between 500 to 800m2 per gram.

The material is made up of 95 to 99% air.

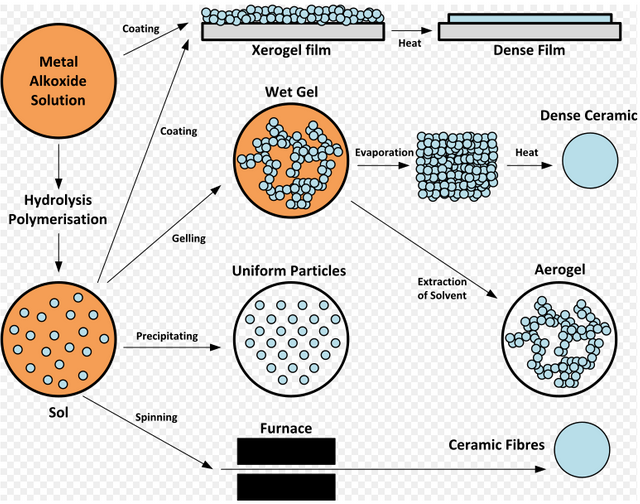

It feels to the touch like that whitish stuff used in packaging most new electronics known as styrofoam.Aerogels were initially produced through the removal of liquid from the gel by immersion in alcohol, water and catalyst. Then the liquid is left to evaporate leaving behind a considerably shrunk gel with enough capacity to withstand some considerable force. The resultant xerogels have a porosity if up to 50%. This method of dring gel was a procedure discovered in 1931 by S.S. Kistler. Xerogel, not to be confused with aerogel, is when the liquid is removed by evaporation from a gel. The porosity here is just 50%, and shrinkage is greater than 90%. But in aerogel, the shrinkage is less or equal to 15% and are made through the application of "supercritical drying". The porosity of silica aerogel is between 0% to 50% 1

The Making of an aerogel

Using a beaker, add TMOS and pour some quantity of methanol to it. Mix the two chemicals properly using a magnetic stirrer. Add some measured amounts of ammonia hydroxide and water to it. Blend or mix all the chemicals very well. The reaction accompanying this blending turns the solution into a gel.

Inject some quantities of this silica into a plastic mould containing methanol.

The methanol undergoes evaporation, after some minutes, and soon a gel coagulant is what is left.

The silica gel, over the course of some days (four times in seven days), is repeatedly soaked in methanol to remove any impurities that may be in the pores of the silica gel. After it is confirmed pure, the next step is to dry it.

Supercritical drying involves a high pressure (about 100 times the average atmospheric pressure) drying process. This process forces liquid carbon dioxide to replace the methanol in the silica gel nanopores.

The carbon dioxide under this condition hits its supercritical state, that is the intermediate state: semi-gas and semi-liquid.

Under this high temperature and pressure, the diffusion occurs on the carbon dioxide without causing a collapse of the nanopores of the silica gel. The solid left behind after this is made up of 99% air and is referred to as the aerogel.

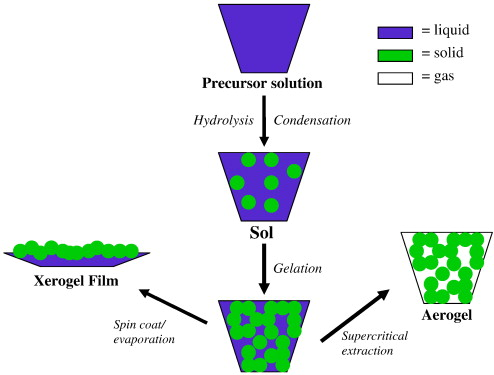

The summary of the process is shown below.

Source

From the sol-gel preparation involving porous materials, the following steps are required.

i. Creation of a coloidal solution ( sol).

ii. Gelation

iii. Drying

Through the process of controlled condensation and hydrolysis, the inorganic salts and alkoxides are formed. That formation leads to a 3-D material known as the stable colloid (sol).

Gelation process is when the colloid or sol (containing a mixture of solid nanoparticles that are dispersed in the liquid, e.g. liquid water with red ink dispersed in it) solidifies into a rigid form while being levitated through a gelation gas mixture.

The next step is the drying; this determines the final product. If the drying is done via evaporation, we have a xerogel. If the drying is via supercritical drying process, we end up with an aerogel.

This supercritical drying is merely a drying process where liquids have transformed a gas via application of temperature and pressure in the absence of surface tension and capillary stress thereby transforming the gels into aerogels.

Supercritical drying ensures the materials nanostructured pores network are not destroyed in the process of the replacing liquid substance with gas.

Applications

Due to aerogel's nano-sized pores, that makes it hard for hot or cold air to pass through, it is a good insulator. It is used in space exploration vehicle (Mars rovers) to protect the electronics from the harsh weather of space. It can provide 39 times more insulation than fibreglass.

Firefighter suits. It is highly heat resistant.

It captures comet dust in spacecraft.

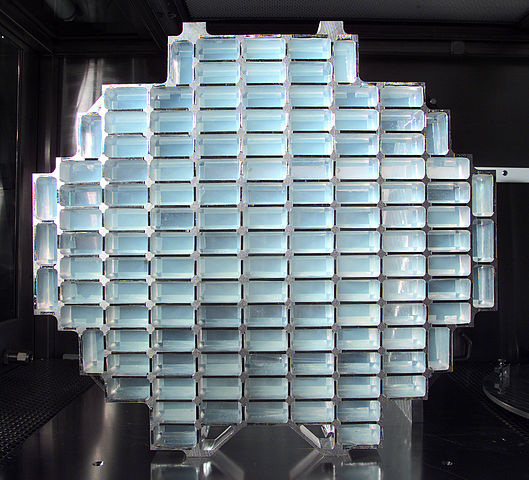

Aerogel is used in the STARDUST space-craft to capture comet particles from the Comet Wild 2.

To collect particles without damaging them, Stardust uses an extraordinary substance called aerogel. This is a silicon-based solid with a porous, sponge-like structure in which 99.8 percent of the volume is empty space. By comparison, aerogel is 1,000 times less dense than glass, which is another silicon-based solid. When a particle hits the aerogel, it buries itself in the material, creating a carrot-shaped track up to 200 times its own length. This slows it down and brings the sample to a relatively gradual stop. Since aerogel is mostly transparent - with a distinctive smoky blue cast - scientists will use these tracks to find the tiny particles.NASA

A block of aerogel could stop particles moving at six times the speed of rifle bullet.

4. Its water resisting property makes it an excellent waterproof paint additive.

References

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details. You can also check this blog post by @steemstem here and this guidelines here for help on how to be a member of @steemstem.

Considering its special microstructure and unique properties, the applications can assume a wide range of utilities.

That's true. Thanks

wow...very aspiring and educational piece...learned things not known...tnx for sharing sir

@vickyrich

Thanks for reading.

Yeah yeah... Science is really not my thing. But I sure did learn from this post like always.. And you wanna know what I learned? Lol...

In a child's voice, I learned that "Sometimes the amazing material is referred to as the frozen smoke. It is the world's lightest solid". Just incase I'm asked in an interview.. Lol... Thanks for sharing @greenrun

Make science your thing and don't miss out on all the fun to be had there :)

Are you on discord sir? Or is there a closer platform we can share ideas?

Is aerogel similar in composition to aerosol? Because aerosol is gotten when solid is dispersed in gas.

Nice piece buddy

There's an aero in both :)

This process reminds me of how we used to make awesome gum using Styrofoam and fuel.

That works too. Thank you.

@greenrun..very aspiring and educational piece...learned things not known...tnx for sharing sir

Thank you too.

I made a holographic glass, helped from youtube tutorial, which can hologram by mobile holographic video.

but This thing beyond of that hologram. Science has no limit

Thanks for sharing. :)

Thanks for reading

Interesting... I bet it feels like touching air.

Neat.

Thanks a lot.

Aerogel has no chemical effect on the environment.I wanted to add this.