Understanding the Design for Cantilever Retaining Wall - 1

Reinforced Concrete Retaining Wall

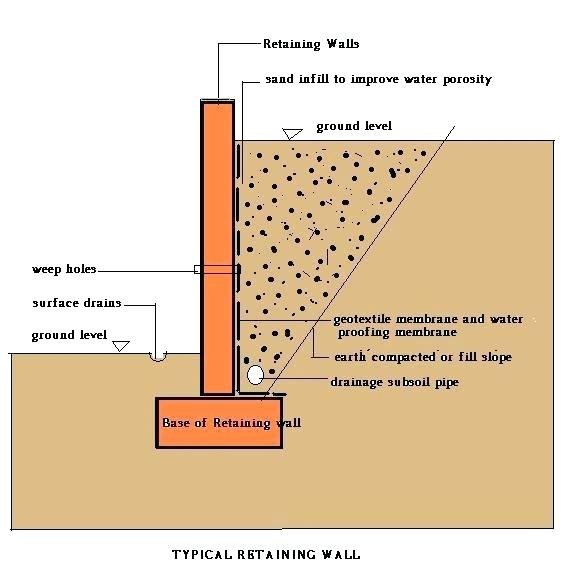

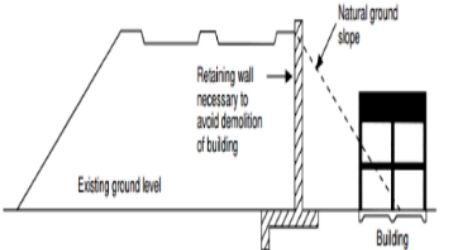

Retaining walls are structures that are used to provide stability for earth or other materials where condition disallows the mass of the material to assume natural shape. It is a term used to refer to a freestanding structure without lateral support at its top a structure that holds or retains soil behind it.

Gravity wall

Gravity retaining walls depends on its weight for stability as its name implies. Where wall with a height that is up to 2m is to be designed, a gravity retaining wall should be the best option to be used. The materials for the construction of gravity walls includes the use of masons such as stones, bricks, tiles e.t.c.

Cantilever Wall

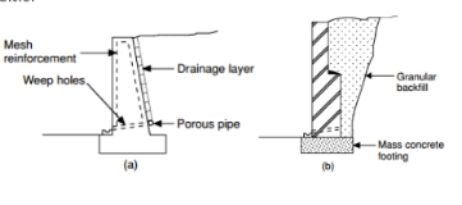

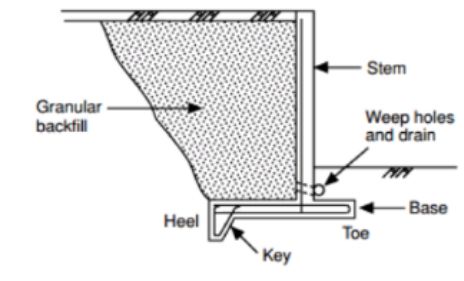

It uses cantilever action for stability. In the case of a cantilever wall the height of wall up to 7m can be designed easily without much stress. The stability of these structures depends mainly on the actual weight of the structure and the weight of the backfill on the base of the structure. A key can be designed for the structure if it is required to prevent sliding failure of the structure.

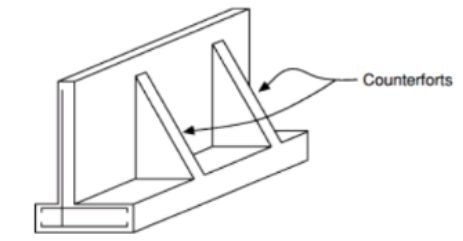

Counterfort Retaining walls

It is Similar to cantilever wall, except that it is used where the cantilever is too long or when there is very high pressures behind the wall. It has a tie – called counterfort - which binds the base and the wall together built at interval to reduce the bending moment BM and shear force SF. Also the weight is used for stability

Buttressed Wall

This is similar to counterfort except that the bracing is put at the front of the wall, and it is compression instead of tension.

Crib wall

This a built up member of precast concrete, metal, or timber and are supported by another pieces embedded in the soil for stability

Semi gravity Wall

These are walls that are intermediate between the gravity walls and the counterfort walls

Reinforced Earth

Walls with strip of metals or geotextiles as a means of providing stability

Retaining wall must be of adequate proportion to be able to withstand or resist overturning, sliding in addition to being structurally sound.

Design Procedures for Cantilever Walls

• Dimensioning

Determine the depth of the foundation from the soil parameter where

angle of repose of the soil = unit weight of the soil

• Determine the coefficients – active (ka) and passive (kp)

• Top width of the stem not less than 200mm

• The bottom width of the stem wall -design to suit the maximum BM arising out of the horizontal pressure of the earth

Width B of the base foundation slab depends on the height H of the retaining wall..

B = 0.5 H to 0.6 H ( without surcharge

B = 0.7 H to 0.75 H ( with surcharge

• Toe projection, tp

• The thickness of the base slab

• Obtain the soil properties

The Structural Design

• Stem Wall

Design for max BM from the horizontal for the height of the backfill.

• Heel Slab

Design for the max BM due to:

Earth pressure at the bottom

The weight of the earth above (neglected at times)

The self weight of the slab

• Toe Slab

Stability Analysis

Drawings

Provision of Construction Specifications

REFERENCES

• Design of Structural Elements Arya

• Structural Use of Concrete Design BS8110

I would like to ask for financial assistance from fellow steemians for my final year project

ESTIMATED COST IMPLICATION

This is calculated in Nigerian Naira and then converted to steem dollars of which the equivalent in sbd is approximately 90sbd at present exchange of 1sbd to #950 of which I have gotten about 20sbd and have about 70sbd more to go.

Any support will be much appreciated Sir/Ma.

Thanks

MATERIALS NEEDED

Based on my mix design ratio proportion of 1:1:2 for concrete and 1:9 for mortar, I will need the following: I will be casting 60 cubes mould of concrete and 60 cubes mould of mortar

• 3 bags of cement = 3 x 2500 = #7,500

• 0.203 tonnes of coarse aggregate = 3000 x 0.203 = #600

• I have gotten fine aggregate for free from an on-going building project on campus.

• Waste glass: I have gotten enough from bars and dumpsites and started grinding into powder

MOULD FOR CONCRETE CUBES AND MORTAR CUBES

I would need three different mould sizes of 150x150x150mm wooden mould, 100x100x100mm wooden moulds and 300x150mm circular pipes.

• 150x150x150mm wooden moulds: I would need 40 of this but I am going to make do with 20 since I am not casting at once. = 20 x 500 = #10,000

• 100x100x100mm wooden moulds: I would need 40 of this also but I am going to make do with 20 = 20 x 500 = #10,000

• 300x150mm circular pipes: : I would need 4 full length of this since it cannot be re-used = 4 x 2100 = #8,400

TESTS TO BE CARRIED OUT

• Chemical analysis of Sand, Cement and recycled glass powder: I am going to be doing my chemical analysis on 9 parameters which includes; silica, alumina, iron oxide, calcium oxide, magnesium oxide, sodium oxide, potassium oxide, sulfur trioxide and loss on ignition. Each of which is #500 each except loss on ignition which is #1,000 = (500 x 8) + 1000 = 5000 x 3 = #15,000

• Fresh state properties: The estimated cost for properties such as setting times, consistency, workability, air content and shear strength = 2000 x 5 = #10,000

• Hardening properties: Cost of conducting test for hardening properties such as density, compressive strength, tensile strength, modulus of rupture and modulus of elasticity is not known yet but I think of budgeting maybe #10,000 for it.

• Durability properties: The cost of conducting test for durability properties such as water absorption, shrinkage properties, chloride resistance and sulphate resistanceis not known as well but I will budget about #8,000 for it.

• Physical properties: physical properties such as bulk density, real density, and modulus of fineness would be done in the school laboratory since the school have the equipments needed for its determination.

Transportation + Miscellaneous = #5,000

ESTIMATED COST IMPLICATION = #84,500 ( A total sum of eighty four thousand, five hundred Naira only)

Just as i have stated in my previous post the following ;

PROJECT TOPIC

Strength properties of mortar and concrete using waste glass as partial replacement for cement and fine aggregate.

ABSTRACT

The glass is widely used and one of the least recycled material in country like Nigeria. Properties of hardened mortar and concrete like compressive strength and workability will be determined for different mix combinations of materials and these values will be compared with the corresponding values of conventional mortar and concrete.

The present investigation has been aimed at to bring awareness amongst the practicing civil engineers regarding advantages of these new mortar and concrete mixes in terms of strength, durability, workability and economy.

PROBLEM STATEMENT

Numerous waste materials are generated from manufacturing processes, service industries and municipal solid wastes. The increasing awareness about the environment has tremendously contributed to the concerns related with disposal of the generated wastes.

Solid waste management is one of the major environmental concerns in the world. With the scarcity of space for landfilling and due to its ever increasing cost, waste utilization has become an attractive alternative to disposal.

AIM AND OBJECTIVES OF PROJECT

AIM OF PROJECT: The main aim of the project is to determine the strength properties (such as compressive strength, tensile strength, workability etc.) of mortar and concrete using waste glass powder as partial replacement for cement and fine aggregate respectively.

OBJECTIVES OF PROJECT: The main objective of this research is to study the effect of waste glass powder on the properties of mortar and concrete mixes as a partial replacement of cement and fine aggregate respectively. Other objectives include:

• To investigate the applicability of recycled glass powder in concrete mixture and mortar mixture.

• To examine the mechanical properties of the concrete with recycled glass as replacement of fine aggregate in concrete.

• To examine the mechanical properties of the mortar with recycled glass powder as replacement of cement in mortar.

JUSTIFICATION

The use of recycled glass powder in concrete and mortar not only makes it economical, but also helps in reducing disposal problems in the environment. Recycling of wastes is considered the best environmental option for solving the problems of waste disposal.

This project study overcomes the issue of the glass waste that is generated from construction and demolition activity. In order to reduce the product of glass waste, it has been suggested to reuse recycled glass waste powder to substitute a percentage of the cement and fine aggregate respectively.