Silicon: Started from Sand, Now We're Here

Ages ago, I wrote about Vacuum Tubes and How Transistors Changed the World. I lied, but it is that kind of innocent lie that parents tell their children when they ask all those awkward questions like from where do babies come. The truth is that silicon is the element we all have to thank for the awesome computer power you and I now have.

It is the key component of computer chips which are made based on the transistor technology, the basis of which was discussed in the above post. But to say that silicon is found in computer chips is like saying that oxygen is found in oxygen cylinders in hospitals because silicon is an extremely common element found in silica (which is a silicon oxide) found in sand.

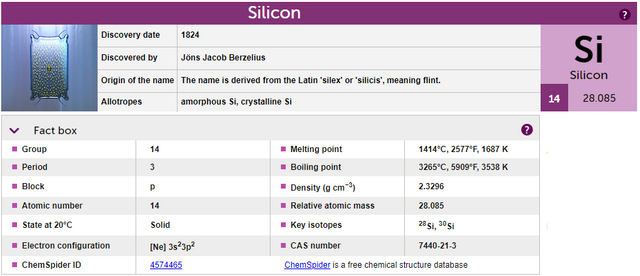

Silicon

Silicon is the principal ingredient in beach sand and is the seventh-most abundant element in the Universe. Apart from Oxygen, it is the most abundant element on Earth. It is also naturally semiconductive which is the property that makes it excellent in the manufacture of computer chips. If silicon is abundant and is the principal component of computer chips, then why aren't they being manufactured all over the world? Well, the answer to this question would become apparent as we progress on this article.

Before we continue, we should differentiate silicon from silicone ( a combination of silicon and oxygen).

Wikipedia CC0Silicone Caulk used as a water and air sealant

Silicones are also known as polysiloxanes. They are polymers which include inert, synthetic compounds made up of repeating units of siloxane. For clarity, siloxane is a chain of alternating silicon and oxygen atoms which are often combined with hydrogen or carbon or both. Silicone is used in applications that are different from computer chips, and these include use in the manufacture of breast implants, menstrual cups, oven mitts and other purposes such as thermal and electrical insulation, cooking utensils, adhesives and lubricants due to their heat resistance.

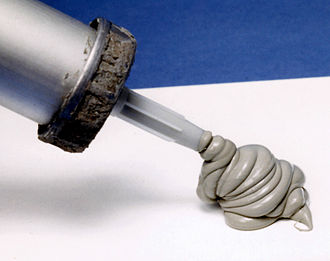

Silicon the Semiconductor

In nature, silicon occurs in the form of silicon dioxide which is otherwise known as silica or quartz (non-crystallized silica). Silicon dioxide is merely silicon attached to a pair of oxygen molecules. As mentioned in this post silicon in neither a conductor nor an insulator, neither a metal nor a non-metal. It is in between the two. You can think of it as a metalloid. Which reminds me of an example our philosophy lecturer gave us in a logic class:

Professor: Premise 1 - Alice's purse is not too big.

Professor: Premise 2 - Alice's purse is not too small.

Professor: Can someone in the class give a sound conclusion from the above?

John: Alice's purse is a leaking purse!

There is no gain telling you that John's name became Leaking Purse from that day onwards. But, unlike Alice's purse, there is nothing wrong with silicon not fitting into either of the above categories. Being in between puts it in a unique position to be manipulated into a semiconductor which are to electronics what oxygen is to human life. Semiconductors conduct electricity in a limited way, but unlike metals, their conductivity increases with temperature.

According to the Chemical Heritage Foundation, silicon was first isolated in 1824 by Jöns Jacob Berzelius, a Swedish chemist, when he heated silica with potassium to purify silicon. However, today, silicon is refined by heating silica in the form of sand with carbon. Even though we are interested in the high tech applications of silicon, we must not lose sight of the low-tech applications such as the production of ceramics and bricks.

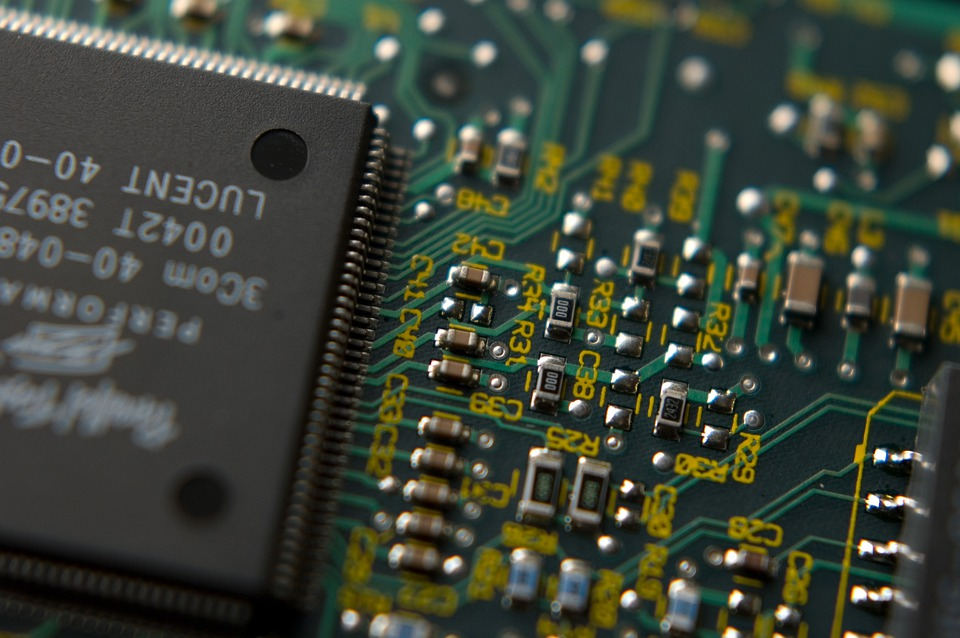

Over the years, the application of silicon as a semiconductor has evolved. At first, it was used to manufacture transistors which were mostly three-legged switches used to provide amplification in radios and which provided the switching capabilities of early computers that enabled them to perform calculations. As time went on, compression and miniaturisation technology improved such that these transistors could be squeezed into a minimal space to make computer chips, solar cells and other electronic switching components.

Silicon is used in solar cells and computer chips. One example of an electronic switch made from silicon is a Metal-Oxide-Semiconductor Field Effect Transistor or MOSFET. Because of the low conductivity of silicon, to make silicon into a transistor, the crystalline form is doped with trace amounts of boron or phosphorous, for example. These trace elements bond with the silicon atoms, therefore leaving some atoms positively charged (holes) and others, negatively charged, and this created a flow of charges from one end to the other resulting in conduction. This flow can be manipulated by changing the current that passes through the semiconductor, enabling it to function as a switch.

From Sand to Computer Chips

In the post about semiconductors, we discussed how two logic gates created from a semiconductor could be used to perform a simple addition of the number 6 and 5 in binary, that's 0110 and 0101. It required an XOR and an AND gate to perform this simple calculation. Now imagine the circuitry that would be required to perform the volume of calculations we assign to our PCs and mobile devices daily.

Wikimedia Commons:Beach Sand

Thankfully, chip manufacturers know how to create millions and sometimes even billions of transistors on processors that are much smaller than the palm of a hand.

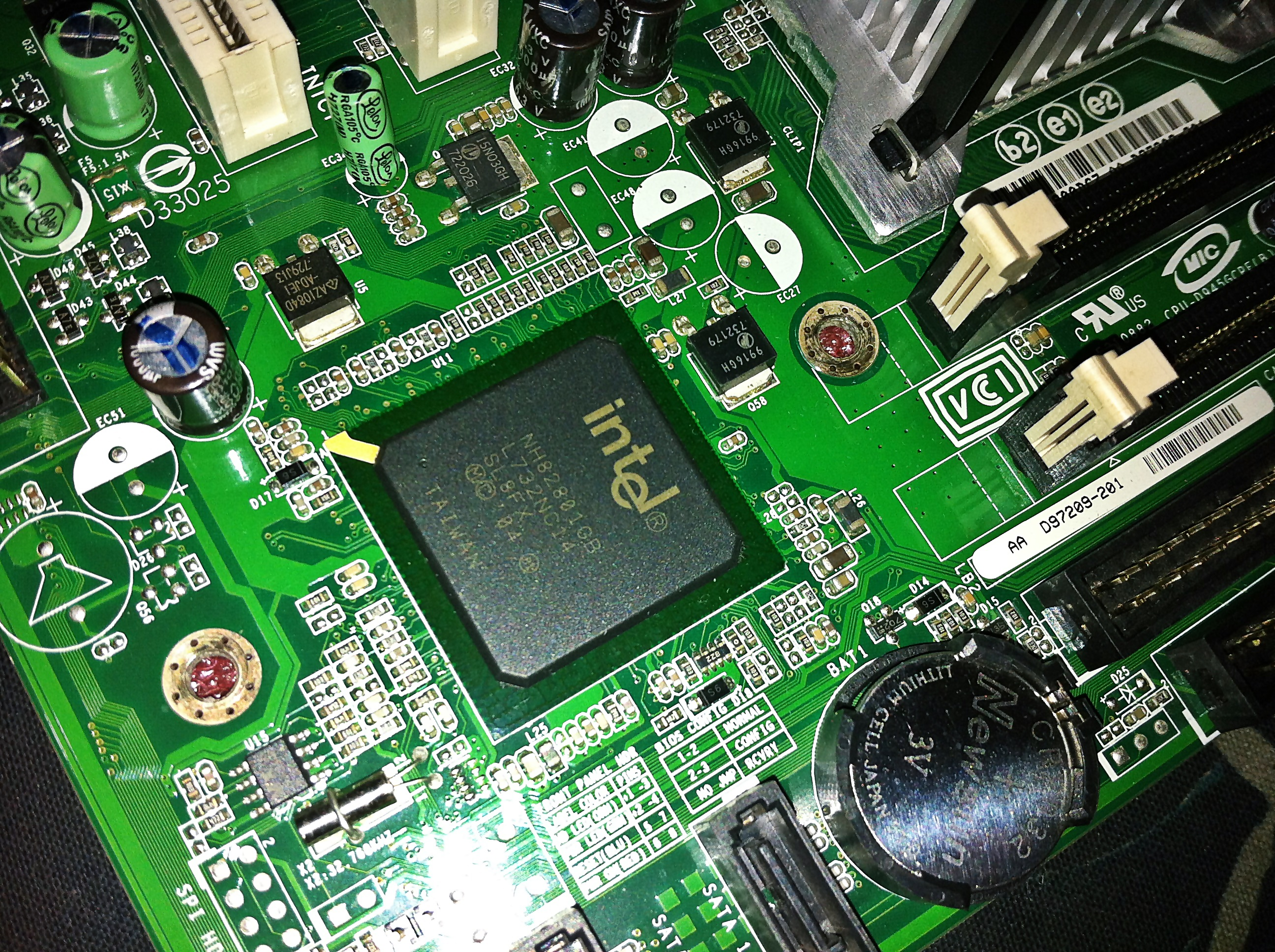

A chip is a processor or a die. It is a microelectronic device capable of processing information delivered to it in the form of electrical signals. This is why the signal must be delivered in the form of 1's and 0's (ONs and OFFs, if you like). These devices look flat even though they can embody up to 30 layers of complex circuitry and the process of creating any particular type would take hundreds of engineers years of planning to specification and testing. Because this technology rides on the back of transistors, the way, the chip functions would depend on how a chip’s transistors and gates are designed and the use of the chip.

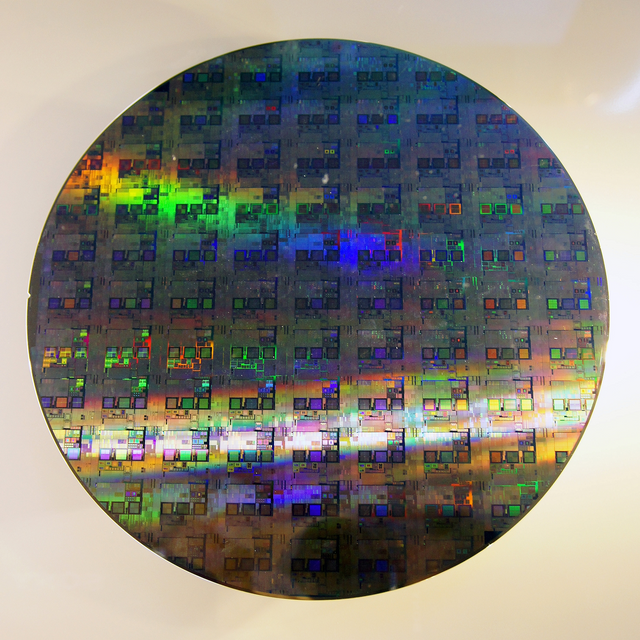

Wikimedia Commons: A 12-Inch Silicon Wafer

Most chips have more than one core. This means that the chips have more than one independent processors on one chip.

The multiple cores in these chips make them faster than the single-core chips. However, the complexity of planning, design and testing is huge. How would something with one billion pieces be put together and how do you create a plan to execute the project timely? Obviously, there cannot be any mistakes. Every step of the process must be precise, and every rule must be obeyed. The engineers would have to work closely together in order to translate the circuit schematics into mask layers for manufacturing.

Source:Intel

New Developments

Some proponents of AI have said that a way to ensure that humans can become as fast as the computers that shall soon have AI capabilities is for human biological intelligence to be merged with machine intelligence. It has been suggested that we may continue to live even when our bodies can no longer support us, if only we upload our memories to the cloud so that it can be embedded in a machine and we could live vicariously through them. This idea always meets with resistance especially from people on my side of the world. However, today's research on silicon is just as science fiction as merging machine and biological intelligence. In 2006, researchers announced that they had created a computer chip that melded silicon components with brain cells. However, here, the idea is to find ways to created electronic devices that can be used to treated neurological disorders from the inside.

Other advances made using silicon include a new type of quantum device that is expected to help produce Quantum computers that are capable of performing calculations in parallel. Researchers are also looking into using silicon to create incredibly tiny lasers called nanoneedles which can be used in place of traditional optical fibres. This provides several advantages including heat resistance and ability to shed heat faster than glass lasers. Whatever the high-tech application of silicon is, the level of precision and sterility required are literally out of this world. For example, the chips are fabricated in rooms that are thousands of times cleaner than hospital operating rooms.

Conclusion

The process of manufacturing chips requires purifying, melting and cooling silicon to form an ingot, which is sliced into disks called wafers. The chips are built simultaneously in a grid formation on the wafer surface such that multiple chips can be made on one wafer. This is done in a fabrication facility or “fab” which is one of the cleanest environments known. The technicians in a fab wear special suits that cover their whole body, called Bunny Suits to ensure that they do not contaminate the working materials with hair or fabric materials.

Wikimedia Commons: Scientists in the Clean Room Wearing Bunny Suits

Based on the ultimate use of the chip, design specifications are made which includes the number of transistors in the chip, the number of gates, the testing and production factors that would serve as inputs to create the schematics that control the flow of electrical current through the chip. The designers would then use computer-aided tools to make comprehensive simulations and to test the chip functions. Then a photolithographic printing is used to print the layers of transistors and make the electrical connections. After the layers are completed, a computer performs a wafer sort test which ensures that the chips perform to design specifications.

The last stage in the process is packaging. The wafer is cut into individual pieces called die. To form a processor, the die is packaged between a substrate and a heat spreader to form what we now know as the processor. The packaging is necessary to protect the die and deliver critical power and electrical connections when it is attached to a computer circuit board, mobile device or some other smart device. Intel has been at the forefront of chip manufacturing, and they make their chips for different applications. This article is being typed by a computer device powered by Intel core i3.5

References

- Live Science | Silicon

- Intel | Transistors to Transformations

- Wikipedia | Silicone

- Royal Society of Chemistry | Silicon

- Intel | Making Silicon

Thank you for reading.

Some special types of silicon are non-toxic, colorless, airtight, and also do not cause chemicals and oxidation processes, are resistant to high temperatures, and can not conduct electricity.

The benefits of silicon for people throughout the industry and the world of health. Silicon is not only beneficial to humans, but also to animals and plants. There is the danger of hiding behind silicone injected into human organs.

Many prominent physicians have issued a silicone injection effect, thoroughly, if silicone injections are not done by a professional medical officer. The dangers of silicon usually affect users who use irresponsible ability to inject silicone.

Thank you for your ever valuable addition. You're appreciated. I believe that it is always a bad idea to try and add any foreign object to the body as it is. Injecting silicone into any part of the body is bound to cause problems sooner or later.

You're appreciated.

Silicon indeed is so important to us. Its application in the tech industry makes it invaluable.

New knowledge added

I love the way you related it to many life situations...The Leaking Purse tho! Nigerian students and nicknames

Thank you for your comment Bro. You're amazing. Yeah, Leaking Purse must be a big man now. I wonder if he would tell his children that his name is Leaking Purse though. Lol :)

Take care man.

LOL..He dare not mention it.

It's a pleasure..You're equally amazing

Thanks. Let's hope we keep amazing each other then... :)

Smiles, Yeah

Brain work @engr.churchboy,your post is always outstanding. Well done.

Thanks a lot man. I appreciate the compliment. Take care, man.

Great article. Highly informative and well written. Great job.

Thanks a lot.

Honestly, you just solved one of my lifelong puzzles, how can somebody say you can use sand to process information, well now I know, all thanks to you.

No one has ever made the explanation this clear to me. You made it real, always interesting to read your articles.

I guess this means I have to keep writing :)

Thanks a lot.

Hey, I remember that last post you wrote some ages ago ! That's not a lie!

Thanks for expanding the topic with this one.

I personally didn't know the difference between the silicon and silicone. (forgive my ignorance) But now I do :D

o.O

Thanks for this article !

Your memory continues to serve you well. I would not have remembered it myself if I didn't write it. I appreciate seeing you here. Thanks a lot for the support.

My pleasure :)