RADIAL ENGINES : PRIME MOVERS OF WORLD WAR II

Don't worry, this is not a story of war, however, the closest many people might have heard about the point of attraction of this post is the World War II. Certainly you've heard a lot of stories about it, and I bet some of those stories involved the mention of aircraft.

Whenever stories are told of heroes though, there are many who feel that the supposed "hero" is only so due to the greater, more indispensable work of other background workers who mostly do not get heroised.

A very practical example of this idea according to one of my friends is how Neil Armstrong is remembered for being the first man to land on the moon, while we all know that there were hundreds of people who worked on the project's most important details to ensure that he got there and returned safely. Yes, there are other pilots who could have taken the trip, but, of course, he will need a functioning rocket to do so, so I ask you : how many of the engineers who developed the rocket do you know. Well we shall discuss that someday else.

In the same vein, you'll agree with me that when the stories of the second World War are told, we hear of Presidents and Military commanders being hailed for their victories in the war. However for a fact some other president and indeed some other military commander could have taken the reins and still succeeded.

However, to win the battles that wrote their names in folklore, these people needed an indispensable "hero" of the story : the aircraft.

These were the real heroes, for unlike the replaceable commanders, they were ultimately needed. We aren't here to talk about aircraft though, it's the heart that kept the aircraft alive and functioning we'll be focusing on- the radial engines.

Simply put, the radial engines where the prime movers of those aircraft in those days, both literally and technically.

The Collins Dictionary defines a prime mover as a means of extracting power from a power source, the power source in this case being fuel.

Radial engines replaced the rotary engines that were used in World War I, and went on to find many applications in different machines. What made them that special and useful, and you're probably wondering why you haven't heard so much about them recently, well, if you're not in a hurry, you are about to find out.

Let's take the words one after the other, then we'll arrive at their composite meaning.

RADIAL according to Merriam Webster dictionary is an adjective used to describe objects having parts arranged or moving along a radius.

Also ENGINES are defined by Wikipedia as a machine used for converting a form of energy to mechanical energy.

So putting both together, we can rightly say that a radial engine is

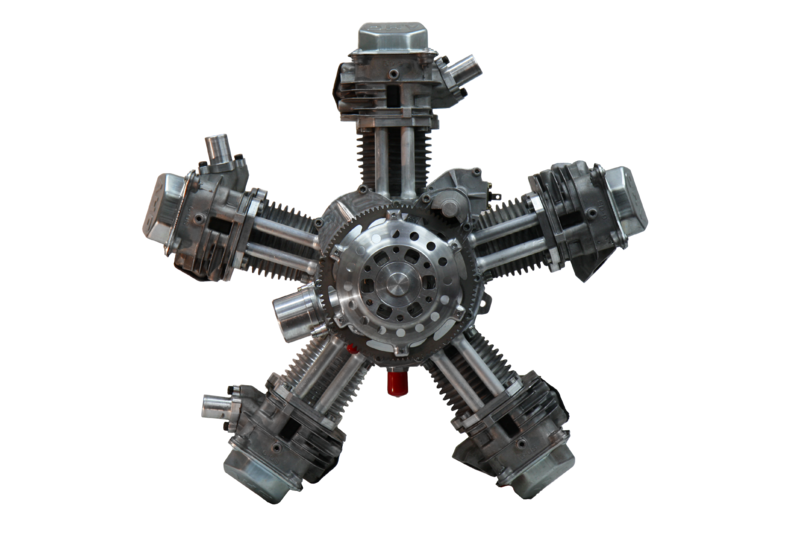

However, the professionals will prefer to define it as a type of reciprocating internal combustion engines configured in such a way that the cylinders radiate outwards away from the crankcase. What they are actually trying to say is that the arrangement resembles a wheel and spoke arrangement in motorcycles.a machine used for converting a form of energy to mechanical energy having parts arranged around a radius.

This gets clearer when compared to the more regular engine types we find around us : the inline engines which have their cylinders arranged in a straight line or the V-shaped engines.

It should be noted here that when viewing this engine from the front, it resembles a star due to the arrangement of its cylinders which gave it the other name by which it is also called - Star Engine.

They operate in the same way as other reciprocating internal combustion engines as will be explained later, however they do so with a shorter crankshaft, since the cylinders are arranged in a circular form.

It is also a four stroke engine, which simply means that while turning the crankshaft through one complete rotation, the piston completes four upward and downward movements called strokes - the intake stroke, compression stroke, power stroke and the exhaust stroke.

PARTS

The radial engine like other internal combustion engines convert the chemical energy derived from burning fuel into mechanical energy through the upward and downward movement of the piston as connected to the crankshaft.

Below are the parts and how they contribute to the working of the radial engine. Please pay special attention to the Master rod and the Poppet valves as they are the main features that describe its working principle.

Cylinders : This is more like a housing or chamber which houses the piston, and it is where the combustion of fuels take place. There are odd numbers of cylinders in a radial engine to maintain the firing order. With an even number of cylinders, that will not be feasible.

Piston : This is housed in the cylinder and does the job of sealing the combustion chamber formed with the cylinder and also compressing the fuel to be burnt. It does the ultimate job of transferring mechanical energy to the crankshaft through its own reciprocating motion.

Crankshaft : This is what receives energy from the piston and through its own rotating motion supplies power to other parts of the machine, we can simply say it takes the final product of the engine to the machine parts that need it. It is attached to the piston with the help of the connecting rod. For radial engines, the crankshaft is much shorter than what is found in regular in-line engines.

Connecting rods and the Master Rod : Connecting rods are usually used to connect the piston to the crankshaft, however, due to the arrangement of radial engines, it will require a special type of modified connecting rods for all the rods to be directly sitting on the crankshaft. These special rods are not easily manufactured. Therefore, one of the pistons of the radial engine has a connecting rod which is directly linked to the crankshaft, this is known as the Master rod, it has rings around it upon which all other connecting rods are attached.

Poppet Valves : Most radial engines make use of the poppet valves which are mounted atop the cylinders, they are moved by push rods, these push rods are controlled by the cam plate. They control the entry of fuel and release of combustion exhaust in and out of the engine respectively.

Cam plate : This in conjunction with the cam lobes and the camshaft ensure the correctly timed movements of the valves for entry of fuel and release of combustion exhaust. The cam arrangement is made to move slowly in the direction opposite that of the crankshaft. The slow movement is ensured by the arrangement of gears. From here on, I'll refer to these as the cam arrangement.

Intake Stroke : The piston is at its lowest position here, allowing fuel to enter the cylinder when the cam arrangement opens the poppet valve at the right time.

Compression Stroke : The piston at this point moves up the cylinder to seal it, thus forming a combustion chamber and consequently compressing the fuel-air mixture.

Power Stroke : At this point, the spark plug ignites at the perfect time to burn the fuel-air mixture releasing a great amount of chemical energy which forces the piston back down.

Exhaust Stroke : The piston moves up the cylinder one final time to push out the left over exhaust from the combustion through the outlet valve, which is also opened by the cam arrangement.

When I was a novice about engines, I had questions about how the piston gets the power to move up the cylinder. However, from further study I learnt the simple, albeit technical truth that the crankshaft carries more than one piston, and the firing order is so arranged to ensure that there is a piston on the power stroke every time the crankshaft rotates.

Therefore, the power from this will be used to drive the crankshaft, in the process, also moving the other pistons that are either directly or indirectly attached to the crankshaft.

Cooling : The radial engine has its cylinders arranged in a coplanar manner, so can be air-cooled, offering a lighter option to the usually heavier water-cooled in-line engines.

Maintenance : They are also easier and cheaper to maintain due to their simpler design, having lesser valves, lesser cam lobes, no water holes and shorter crankshaft.

Speed reduction : Radial engines usually operate at lower revolutions per minute (rpm), thus speed reduction may not be needed to drive low speed propellers.

Drag : To be air-cooled, the cylinders have to be exposed, thus contributing to drag.

Installation :For the engines to be air-cooled when deeply buried, serious technicalities are involved in the installation.

For its limitations and other reasons like the need for more power, radial engines have bee replaced by gas turbines.

However, some radial engines are still in use today. A very good example is the M-14P used on the Yavkolev aircraft manufactured by Vedeneyev. Another is the R180 5-cylinder by HCI aviation.

It is worthy of note that radial engines were the rave of their own moment, but now, their use is greatly reduced, in fact to the extent very few know well about them, this simple fact may be a reality check that the engines that are the rave of today's moment, may take the back seat in future years.

However, what we do know is that whatever engines will be in use hundred years from now, they'll make today's elegant engines look archaic.

REFERENCES

HOW RADIAL ENGINES WORK | RADIAL ENGINES | INTERNAL COMBUSTION ENGINES | FOUR STROKE ENGINES

The radial engine is not as popular as the "V" and "in-line" engines.

I love your introduction, it pulled me in.

Awesome post!

You're very right about its popularity, it's one of the reasons I chose to explain it. Thanks for reading.

Once again, a beautiful read!

Keep it up!

My student.. The way you took time to write this post on radial engine is encouraging. I haven't seen the radial arrangement till you gave me a lecture on it today. Thank you for taking the time to educate us on the radial arrangement of the IC engine.

My mentor, thanks for always being there, and for stopping by to read

@sogless Even though it's a familiar topic. I was compelled to read by the intro... Well done sir.

Thanks for reading and for your upbuilding comment.

This is fabulous. You're good with words and surely know how to attract people.

The world of combustion engines is an interesting phenomenon around it. The listed parts and process are becoming registered in my head has I've had lot to do with them in the past 4 years being an engineering student. It's good to get refreshed and re-informed.

Thanks for sharing this.