THE TORQUE CONVERTER AND HOW IT WORKS

Hello and welcome to my blog, hope this post meets you well. As for me, my week has been stressful for a while and I am still trying to recover.

As we all know, the automobile is powered by an engine (internal combustion engine) and the power is transmitted to the wheels via the transmission system. The transmission system serves as the intermediary between the engine and the wheels and also functions to facilitate the changing of speed. Transmission system of the automobile is mainly divided into two types; the manual transmission and the automatic transmission. In this vein, automobiles can be named according to their transmission system; manual or automatic vehicle.

From the driver’s seat, the major difference between the manual and the automatic vehicles is the absence of a third pedal (the clutch pedal) and a simple gear stick in the automatic vehicle. You can conclude that the absence of a clutch pedal implies the absence of a clutch in the system. Therefore, you would be right if you conclude further that an automatic transmission does not employ the use of a clutch to engage and disengage the transmission from the engine.

But if it doesn’t use the clutch, what does it use?

In this post, I already talked about the highly important part of the manual transmission system; the clutch. Instead of having a clutch, the automatic transmission employs the use of a component called the torque converter to engage and disengage from the engine output and the beauty of this is, there is no need for the driver input. The torque converter does the same work as a clutch (connecting and disconnecting the transmission from the engine) but it does it in a different way.

Lets talk about the torque converter

THE TORQUE CONVERTER

A torque converter is a type of fluid coupling (a hydrodynamic device that is used to transmit power) which is employed to transfer power from a prime mover (automobile engine) to a driven load.

Comparing it with the clutch, the torque converter transmits power via a fluid while the clutch transmits by friction.

How do I mean?

In order to transmit the power from the engine to the transmission, the clutch must have contact with the moving part of the engine (the flywheel) but in the case of the torque converter, there is no physical contact but instead, a fluid does the job (I am not talking about fluids in a tube under pressure as in the hydraulic brakes).

How about a little physics?

Explaining torque, I would need to introduce some terms such as “moment” and “couple”

Torque is defined as the turning effect of a force about a given point. It is sometimes referred as same with moment. It is however, a special case of moment.

A couple is a pair of equal forces that act in opposite direction.

Invariably, torque can be defined as the moment of a couple or the moment of a force! You might be wondering why i am digressing. Well, I have been part of a debate about the difference between moment and torque and here is what I could conclude;

moment and torque are relatively the same but their use depends on the scenario that is intended to describe.

Enough of the debate, lets talk about torque.

Torque is a vector quantity as it has magnitude and direction.

Mathematically, torque is the product of force and perpendicular distance

τ = F×L

Class dismissed!

Now back to the torque converter; one characteristic that makes the torque converter different from other forms of fluid coupling is its ability to multiply the torque.

The torque converter is not found only in the automobile, it can be found in propulsion systems of marine machines, mechanical power transmission in industrial setup such as the conveyor drives, forklifts, drilling rigs, railway locomotives, winches and construction equipment. As you all (or some of you) would already know, I would concentrate on the torque converter in the automobile.

ILLUSTRATIONS? YES OF COURSE!

How about a little exercise?

Well, this might not pass as a physical exercise, it is more of a mind exercise. Imagine you have a simple Dj turntable (or whatever it is called), get a fairly large bowl and place it (in your mind of course, stay with me!) on the turn table right in the middle (ignore the pointed tip of the turntable which might prevent balancing in the middle). Now turn on the turntable to spin slowly. As expected, the bowl would rotate with the turn table.

Now let’s add a little twist to it.

Add some water into the bowl, the water should fill up to one third of the bowl. Now place another bowl of slightly smaller diameter face down inside the bowl. Turn on the turntable once again and use your finger to hold the smaller bowl slightly.

I expect you to experience this; the bigger bowl spins with the turntable as usual and also taking the water along. The smaller bowl however is not rotating because your finger is on it and it is resisting the motion. This resistance is possible because the turn table is spinning slowly.

Increase the speed of the turn table to a very fast one (I don’t think that’s possible with a real life turn table) and gradually release your finger from the smaller bowl.

Here is what is expected;

The bigger bowl spins with the turn table (as usual) and the water climbs up the wall of the bowl (pretend it doesn’t splash) and as a result, carries the smaller bowl in the same direction. The smaller bowl is not in contact with the bigger one but spins at almost the same speed as it.

This is a simple illustration of how the torque converter works

P.S this is not quite achievable in real life but it should present the picture I intend painting.

How about another experiment?

This time around, the experiment can be as physical as required. Here it goes;

Get two fans of the same size and place them facing each other. Plug on to the power supply and leave the other unplugged. Now switch on the first fan and gradually examine what happens.

Here is what is expected;

At lower speeds of the fan, the blades of the unplugged fan rotate very slowly or might not even rotate at all relative to the working fan. But as the speed of the first fan increases, the second fan blades begin to speed up in relation to the first and could attain a speed almost equal to that of the first fan.

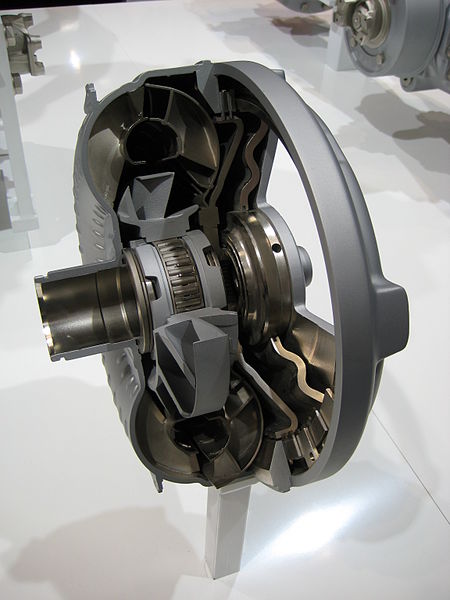

WHAT LIES WITHIN THE TORQUE CONVERTER

Just like any other hydraulic coupling, the torque converter has three major components; the pump (and housing), the turbine and the fluid. The components that differentiates the torque converter from other types of fluid coupling is the stator.

- THE PUMP AND HOUSING

The housing as the name implies is the part that encompasses the whole torque converter arrangement. From outside, all you would see is an oval shaped, doughnut-like component that is the housing. The housing is attached to the flywheel of the engine and thus rotates at the same speed as the engine.

The pump is also attached to the housing and thus, rotates at the same speed as the housing and the engine flywheel. The pump is made of fins that protrude outwards and thus functions to fling the fluid in the compartment to the outer circumference where it enters the turbine. The “pump” as the name implies functions like a centrifugal pump.

Operation of the pump is just like in the washing machine, the “spin cycle” spins and flings the water and clothes to the outer part of the wash tub.

- THE TURBINE

Very similar to the pump and facing the other direction is the turbine. You can say the turbine is the same as the pump but rotated at 180 degrees! It is mounted independently of the pump and housing and it is attached to the transmission. The fluid flung by the pump is received by the turbine and this causes it to rotate in the same direction (just like the smaller bowl or the unplugged fan). The fluid is received from the outer part of the turbine and is directed to the middle and thus is returned to the pump input.

- THE STATOR

If you examine critically, when the fluid hits the turbine and is directed in the opposite direction towards the pump. If it returns to the pump like that, it would slow it down and thus, power would be wasted. In order to prevent this from happening, the stator is introduced.

The stator lies in between the pump and the turbine. It functions to redirect the fluid coming from the turbine before it hits the pump again. The blades of the stator are designed such that it completely changes the direction of the fluid before it hits the pump. The stator is also attached to a one-way clutch which is coupled to a fixed shaft in the transmission therefore, the stator cannot be affected by the direction of the fluid and it can aggressively force the fluid to change direction. That way, the efficiency of the torque converter is improved.

The stator is the component that affects the ability of the device to multiply torque as against other types of fluid coupling which experience high slippage and power loss due to the returning fluid opposing the direction of the fluid flow in the pump.

NOW LETS TALK ABOUT HOW THE TORQUE CONVERTER WORKS

Just like in the illustrations I made above, the simple working principle of the torque converter is as follows:

The fluid enters the torque converter via the pump and as the engine spins, the fluid is flung to the outer part and is then received by the turbine which is forced to rotate as a result of the direction of the fluid. This rotation is the power delivered to the transmission. The reversed direction of the fluid is corrected by the stator before it hits the pump to prevent loss of power. This cycle continues as long as the engine runs.

You might be wondering how the torque converter accommodates for the needed disconnection when there is need to start the vehicle or change the speed. Well, here it goes

The operation of the torque converter is divided into three stages

THE STALL

Assume you are stopped at a light. The engine is running but the vehicle des not move because your feet is on the brakes. Just like the word suggests, the stall is when the engine runs but the turbine cannot rotate. At the stall stage, the pump and the turbine are at different speeds with a very large difference between the speeds. This stage usually lasts for a brief period when the vehicle just starts to move.THE ACCELERATION

At this stage, the vehicle is accelerating but the speeds of the pump and turbine are still largely different. The torque converter produces torque multiplication less than what is achievable at the stall stage. Multiplication of torque depends on various factors including the difference between the pump and turbine speeds.THE COUPLING

At this stage the pump and the turbine speeds are almost equal with the turbine speed at almost 90% of the pump. The process of torque multiplication has stopped and the device behaves like a simple fluid coupling.

many torque converters have a lock-up clutch which functions to lock when the speeds of the pump and the turbine are almost equal. This is introduced to eliminate losses due to the fluid drive and the device functions as a mechanical device. The lock up clutch disengages automatically with reduction of speed.

SLIPPING

This occurs when there is delay in shifting or the transmission slipping out gear. This can be caused when the transmission fluid is not enough or too much. The effects of slipping can be a loss of acceleration and reduction in fuel economy.OVERHEATING

Overheating can easily be noticed from the temperature guage in the vehicle. This can be caused by a drop in the pressure of the fluid as a result of faulty torque converter, low fluid level or malfunctioning solenoid. If the converter overheats, it would be unable to transfer power to the transmission. Effects of overheating include; poor throttle response and wear and tear within the transmission.STRANGE AND UNUSUAL SOUNDS

If the torque converter begins to fail, one might begin to hear some sort of “whirring” or “clinking” sound either from a bad bearing or broken turbine.HIGHER STALL SPEED

As stated earlier, the stall speed is the speed at which the torque converter is able to transfer power to the transmission. A bad torque converter would take longer to engage the engine i.e. a higher stall speed.

Torque converter problems can be caused by any of the following ;

- damaged seals

- Bad needle bearings

- worn torque converter clutch

- faulty solenoid.

If you notice any issues concerning engagement of the transmission in your automatic vehicle, endeavor to take it to a trusted auto mechanic. If you are not trained to, do not attempt to fix it.

CONCLUSION

The torque converter is a very important part of the transmission of the automatic system. It is quite different from the clutch of the manual transmission but it occupies the same position as the clutch. The major difference between the two is that the clutch is a type of friction coupling while the torque converter is a fluid coupling.

It is important to always ensure to use the specified Automatic Transmission Fluid (ATF) for your vehicle and also ensure the ATF is enough.

REFERENCES

torque converter | how a torque converterworks | how does a torque converter work | how do torque converters work? | torque converter problems | fluid coupling

It was fun to read even though I knew all this stuff ;). My guess is that you are a Mechanical Engineer.

You are right with that guess. I am enthusiastic about automobiles.

Thanks for reading.

wow..nice and amazing. Thanks for sharing @rharphelle

I particularly enjoy the simple approach you used. It is easily relatable.

Thank for the illustration, I hope I don't find myself trying them out!

The torque converter releives us of the stress of clutching intermittently. During my driving training, it was one of the weak points I trained one for a majority of my time there.

Nice article u've got here.

Lol, like i said in the first illustration, do it in your mind! You can try out the second one though.

Lol. Noted!

Those illustrations just made the whole idea if the torque converter so easy to relate to. You reminded of my Internship days at an auto-mechanic workshop. You've done a very great job.

Thank you for your kind comment.

The mission is to present it in the simplest way possible.

I am glad i could connect

Yes you connected. I just hop in and drive. Makes sense to know what actually happens

Thanks for dropping by

The torque converter is a very powerful tool in an automobile.. Really great improvement over the clutch.

Ofcourse its an improvement. Thanks for reading through.

You are welcome.