DESIGN AND CONSTRUCTION OF A MINI WIND TURBINE - PART ONE

Hello #steemians. I hope this meets you well. I want to quickly share light on a project I recently tried my hands on - a Mini Wind Turbine that could prove helpful in powering our domestic appliances. In this post, I would be sharing the processes and materials needed in actualizing this project. Stay with me.

INTRODUCTION

With increasing awareness of global warming due to carbon dioxide from the burning of fuels, the use of natural energy source is coming into effect. Engineers are adapting the use of natural resources (e.g. wind, solar, hydro etc.) to generate electricity and to provide power to power plants. The use of wind turbine is one of the oldest known methods of extracting energy from the natural resources. Windmills are used in the olden times to run the pump for pumping water from the well. Wind turbines are not well considered because they heavily depend on the wind blowing along with the geographical disturbances. However, a small scale or mini wind turbine can be used to power small home appliances reducing the cost of electricity and fuel burnt to produce equal amount of electricity.

Wind turbine extracts energy from the wind to generate electricity and could generate enough power to run household lamps and other electrical appliances. This project looks to consider the design requirements, the materials needed for its construction and its actualization.

With the geographical orientation in mind, We intend to improvised a gear system which would help improve the rotational speed of the turbine so as to increase the power output. When two meshed gears have a different number of teeth, there exist a reduction or increase in speed. The gear ratio of a gear set tends to determine the delivered speed at the driven end. For this project, we would look to improvise a spur gear set of gear ratio 1:5 so that we could have about five times increase in the speed delivered from the driving gear to the driven gear.

PROBLEM STATEMENT

Electricity fluctuation is a big worry here in Nigeria and such, it compels us to continue to look at means of getting alternative source of power especially for our domestic appliances. In recent time, people have been compelled to adopt the use of electric generator as a means of survival. As a consequence, there is increased degradation of the ozone layer and hence, global warming through the release of carbon monoxide from the exhaust of these generators. Some people on the other hand are with fewer options and have had to turn to the local means which includes the use of kerosene lanterns, touch lights and even candle in some cases as source of lightning.

This problem inspired this project. As earlier stated, a small scale or mini wind turbine can be used to power small home appliances, hence, reducing the cost of electricity and fuel burnt to produce equal amount of electricity. So, we look to solving this problem by designing a mini wind turbine using a gearing system that allows it to generate enough electrical power to serve domestic needs.

AIM AND OBJECTIVES

Aim of Project

The main aim of this project is to design and construct a mini wind turbine that can generate electricity for domestic use by improvising a gearing system that improves the output from the setup.

Objectives of Project

The following are the objectives of the project:

- To design the requirements for a mini wind turbine that can generate electricity for domestic use.

- To fabricate and construct the setup of the mini wind turbine.

MATERIALS AND METHOD

Materials

In actualizing this project, the following materials form the major components of the mini wind turbine set-up:

- Metal sheet fabricated fan blades

- Synchronous generator

- 10mm iron rod

- Flat metal sheet

- Fasteners: nuts and screws

- Teflon spur gears

- Threaded shafts

- Rectifier

- AVR (voltage regulator)

- Inverter

- Batteries

- Ball Bearing

- Electrical wire

Method

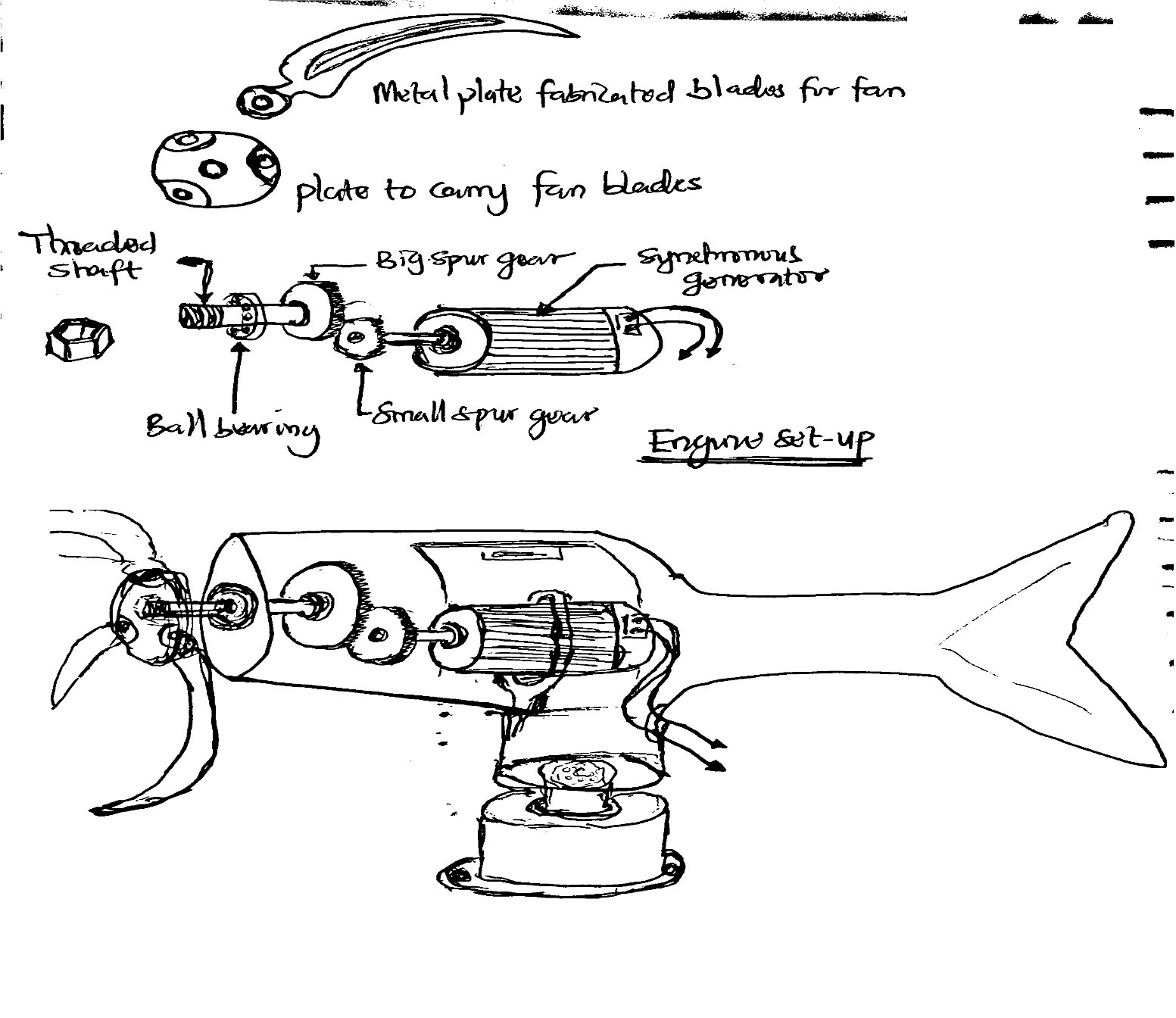

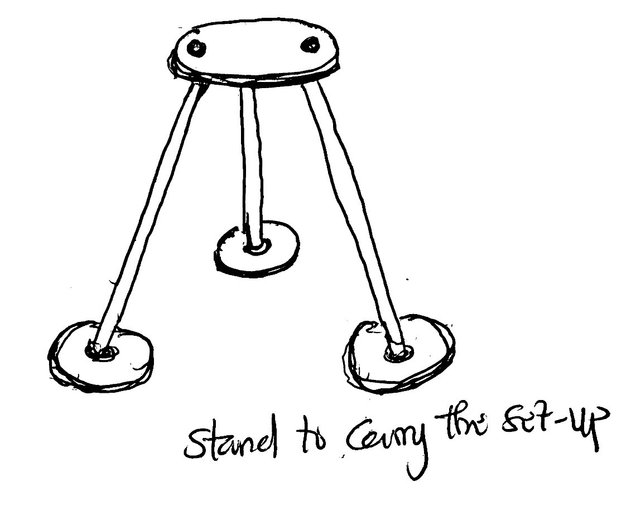

The setup below represents the schematic of the components of the proposed project:

The mini wind turbine will have a 3 blade fan fabricated from PVC which will be fastened to a threaded shaft using nuts. The shaft connected to the fan would carry the big spur gear having 60 teeth while the shaft extending from the synchronous generator will carry the small spur gear having 12 teeth. With this gear setting, we can achieve the five times increase in speed we look to achieve. This can be seen from the relationship below:

RPMdriven = RPMdriving × (number of teeth of the driving gear)/(number of teeth of the driven gear)

Say the fan rotates with a speed of 100rpm from the effect of wind, the driven gear speed, hence the generator speed can be calculated as:

RPMdriven = 100 × 60/12

RPMdriven = 500rpm

From the rotation of the generator, a variable output is generated hence the setup below is needed to convert the output to a usable form for domestic use:

| Variable output from the generator | Rectifier for converting output irregularity | AVR voltage regulator | Inverter for converting the DC output to AC output | Battery for storing the energy for later use. |

The output can then be harnessed for the intended domestic use.

Machining Operations

The following are the machining operations that would be performed for the actualization of project:

- Threading

- Fastening

- Fabricating

- Welding

- Drilling

BUDGET

Two spur gears - #2,000

Synchronous generator - #7,000

Two ball bearing - #2000

Rectifier - #1,500

AVR - #800

Iron rod (2m) - #3,000

Metal plate - #3,000

Others - #3,000

TOTAL #22,300

CONCLUSION

With the following represented set-up actualized through the stated machining processes, the mini wind turbine with an improvised gearing system which will increase the rotational speed delivered to the synchronous generator and hence, an increased power output can be actualized. This will prove useful in catering for the domestic power requirements in the homes and farms and hence improving productivity.

In the other part of this post, the resulting product will be displayed and analyzed. Thanks for reading.

Interesting project you've laid your hands on @mrbreeziewrites...Good job well done!

Beautiful report!

One of the beauty of Engineering practice...!

Thanks for the kind words. I appreciate you checking out my blog.

Yeah, practice makes it more fun.

@onequality @hr1 @originalworks

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by Mrbreeziewrites from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.

@originalworks

This post has received a 0.05 % upvote from @drotto thanks to: @banjo.