How does the Powerful ultra-bright LED device work ?

Lighting devices, where ultra-bright LEDs are used as light sources, will not surprise anyone. The demand for such devices is constantly growing, this is directly related to the low power consumption of these devices. Considering that about 25-35% of the consumed electricity is spent on lighting, the savings will be quite appreciable.

But given the relatively high cost of ultra-bright LEDs, due to their design features, it's not timely to talk about a complete transition to this type of lighting. According to experts, this process will take from 5 to 10 years, that's what it will take to debug and introduce new technologies.

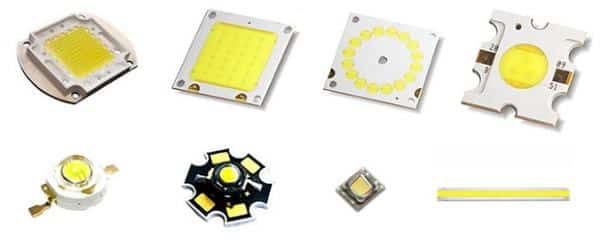

Different kinds of super-bright LED light sources

But given the relatively high cost of ultra-bright LEDs, due to their design features, it's not timely to talk about a complete transition to this type of lighting. According to experts, this process will take from 5 to 10 years, that's what it will take to debug and introduce new technologies.

Briefly about the effectiveness

The efficiency of the lighting device is considered to be the ratio of the luminous flux produced (measured in lumens) to the consumed electricity (watts). Quality lamp with filament has an efficiency of about 16 lumens per watt, fluorescent (energy-saving) - four times more (64 lm / W), for long day lamps this figure is around 80 lm / W.

The efficiency of ultra-bright LEDs, produced massively at the current time, is about the same as that of fluorescent lamps. Please note that we are talking about mass production. As for the theoretical limit for ultra-bright LED sources, it is determined by a threshold of 320 lm / W.

As many manufacturers promise, in the next few years, the efficiency can be increased to the level of 213 lm / W.

The influence of design features on the cost

For the manufacture of ultra-bright LED light sources, one of two methods can be used:

- To get light close to the spectrum to white, three crystals are used installed in one housing. One is red, the second is blue and the third is green;

- a crystal emitting in the blue or ultraviolet spectrum is used, it illuminates a lens coated with a phosphor, and as a result, the radiation is converted into light close to the natural spectrum.

Despite the fact that the first option is more effective, its implementation costs a bit more, which negatively affects the prevalence. In addition, the spectrum of light emitted by such a source differs from natural.

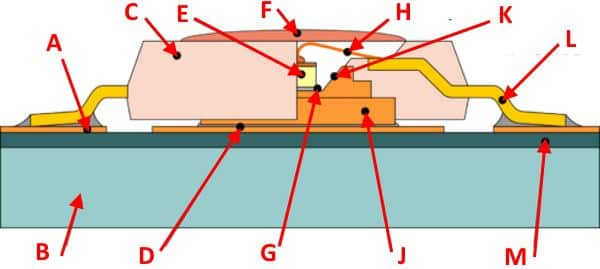

Devices manufactured by the second technology have less efficiency. It should also be taken into account that the phosphor contains a composite composite based on cerium and yttrium, which in themselves are not cheap. Actually, this explains the relatively high cost of ultra-bright white light-emitting diodes. The construction of such a device is shown in the figure.

Super bright LED device

Notation: A - printed conductor; B - base with increased thermal conductivity; C - protective housing of the device; D - paste-solder; E - LED crystal emitting ultraviolet or blue light;

F-luminophore coating; G - glue (can be replaced by a eutectic alloy); H is the wire that connects the crystal and the terminal; K - reflector; J - heat sink base;L - power output; M is the dielectric gap.

Mounting Features

The high-brightness LEDs are affected by the degree of heating of the crystal and the p-n junction itself. The first depends directly on the life of the device, from the second - the level of light flux. Therefore, for a long service of super-bright LEDs, it is necessary to organize a reliable heat sink, this is done using a radiator.

It should be taken into account that the thermal conductive bases of these semiconductors, as a rule, conduct electricity. Therefore, when several elements are installed on one radiator, care should be taken to ensure reliable electrical insulation of the bases.

A good heat sink significantly increases the service life of ultra-bright LEDs

The rest of the mounting rules are practically the same as for conventional diodes, that is, it is necessary to observe the polarity, both with the installation of the part itself and with the power connection.

Features

Given the relatively high cost of ultra-bright LEDs, it is very important to use reliable and high-quality power supplies for their operation, since these semiconductor elements are critical to current overload.

After a non-standard mode, the device may remain operational, but the power of the radiated flux will be reduced significantly. In addition, this element is likely to cause breakdowns and other connected LEDs.

Before talking about drivers for super-bright LEDs, we will briefly describe the features of their power supply. First of all, it is necessary to take into account the following factors:

- the power of the light flux emitted by these elements directly depends on the amount of current flowing through them;

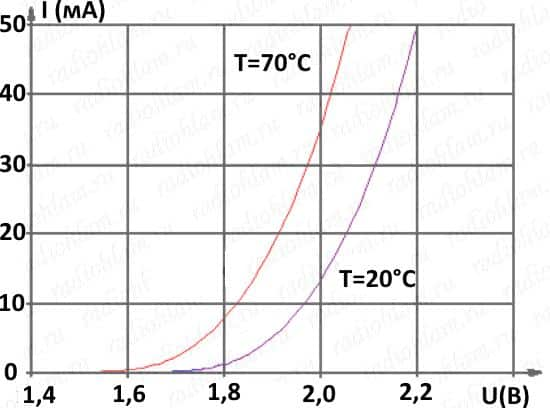

- Characteristic for super-bright LEDs is a non-linear I-V characteristic (current-voltage characteristic);

- temperature has a strong influence on the I-V characteristic of these semiconductor devices.

Below is shown the variation of the I-V characteristic at the temperature of the semiconductor element (super-bright smd-LED) 20 ° C and 70 ° C.

The change in characteristics from the effect of temperature

As can be seen from the graph, when a stable voltage of 2 V is applied to a semiconductor, the electric current passing through it varies depending on the temperature. When the crystal is heated at 20 ° C, it will be equal to 14 mA, when the temperature rises to 70 ° C, this parameter will correspond to 35 mA.

The result of this difference is the change in the power of the light flux at the same supply voltage. Proceeding from this, it is necessary to stabilize not the voltage, but the electric current passing through the semiconductor.

These power supplies are called LED drivers, they are conventional current stabilizers. This device can be purchased ready-made or assembled independently, in the next section we will give a few typical driver schemes.

Homemade LED driver

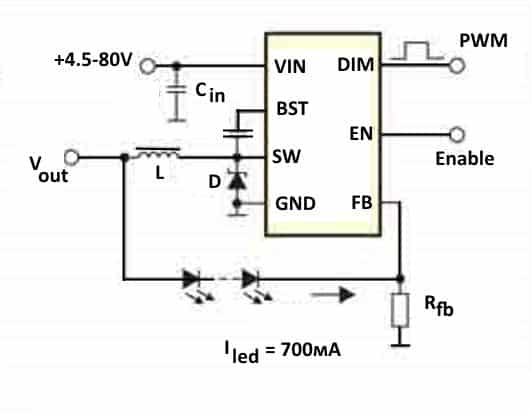

Let's take few driver options based on the specialized Monolithic Power System chips, the use of which greatly simplifies the design. The diagrams are given as an example, a full description of the typical inclusion can be found in the datasheet on the chips.

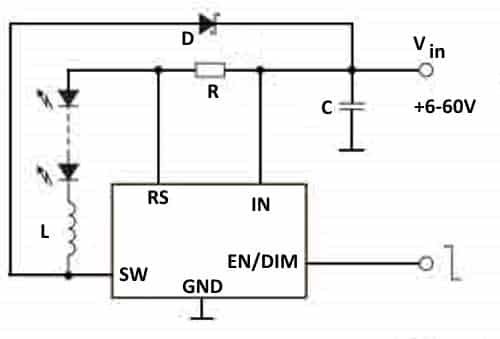

The first variant is based on the down converter MP4688.

Example of inclusion МР4688

This driver can work with voltages from 4.5 to 80 V, the threshold of the maximum output current of 2 A, which allows you to power the luminaire on high-brightness, high-power LEDs. The level of the electric current passing through the LEDs is regulated by the RFB resistance. The PWM dimming with a frequency of 20 kHz allows smoothly changing the current flowing through the LED.

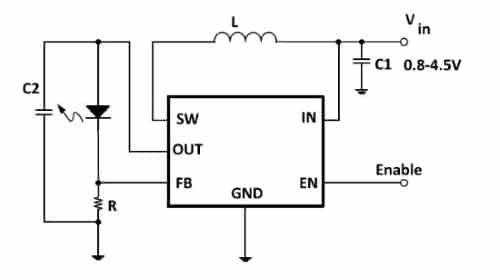

The second version of the driver based on the microcircuit MP2489. Its compact case (QFN8 or TSOT23-5) makes it possible to place the driver in the MR16 base, used by halogen lamps, which allows replacing the latter with LED lights. The typical connection diagram of the MP2489 is shown in the figure.

Driver based on MP2489

The above circuit allows you to include two parallel LEDs, each with a working current of 350 mA.

The last version of the driver based on the chip MR3412, which can be used in portable flashlights. A distinctive feature of such a scheme is the possibility of working from a finger nut AA.

Driver for flashlight based on MR3412

References for Images:

- https://learn.adafruit.com/all-about-leds?view=all

- https://www.elprocus.com/led-light-sources/

- http://www.nutsvolts.com/magazine/article/practical-led-indicator-and-flasher-circuits

- https://www.aliexpress.com

References for Text:

- http://www.theledlight.com/technical1.html

- https://en.wikipedia.org/wiki/Light-emitting_diode

- http://www.instructables.com/id/high-power-LED-grow-lights-M.k2/

Support @steemstem and the #steemstem

project - curating and supporting quality STEM

related content on Steemit

thanks for sharing

Note that the second paragraph is written twice :)