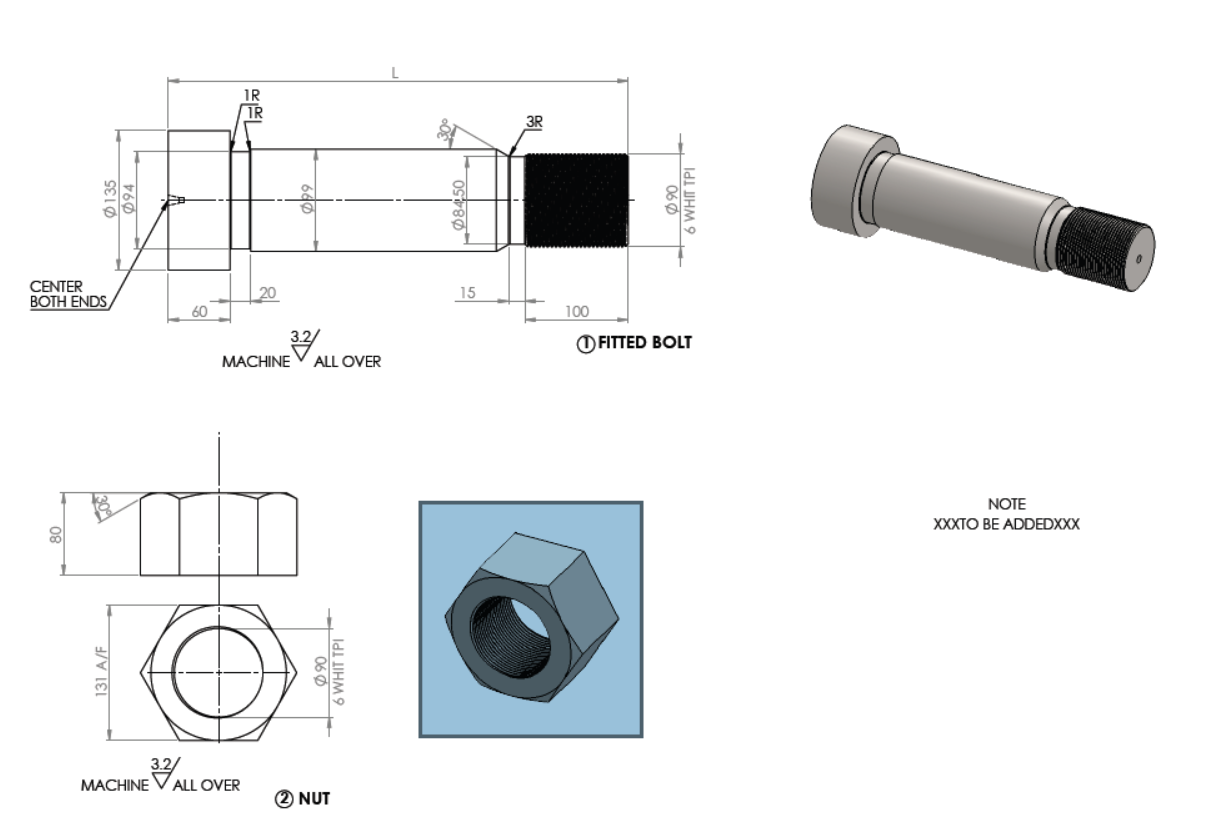

Engineering Design: TURBINE SHAFT FITTED BOLT

Couplings constitute one of the most difficult bolted joints to properly secure. And yet they have in deed existed from since the earliest days of industrialization. Early simple machines like windmills required and exercise some way of connecting shafts. With the invention however of the steam turbine some time in 1884, shaft coupling became essential for power generation especially but also in shipping industries.

Ever since then, turbines have increased in size, and with them, the amount of the power and the torque needed to be transmitted. As a consequence, the demands on shafts and couplings have equally increased. In the particular case of bolted couplings, the demands have in deed increased on the bolts themselves.

With hindsight, despite having been around and used for so many decades now, todays coupling is no different from yesterdays’ in terms of design and concept. The Engineering behind them has however evolved. When you look at the bolt specifically, it has gone through years of improvement sophistication, today as opposed to decades ago, even smaller couplings transmit a lot of Torque.

One of the key functions of bolted couplings is the maintenance of shaft alignment, a requirement for safety and efficiency in marine applications as well as power generation applications.

In Marine applications for example where shafts usually turn at low speeds, misalignment leads to vibrations. This in turn unnecessarily increases the loading on bearings. For the case of power generating applications, rotation is normally as high as 3,600 revolutions per minute (rpm). Vibration due to misalignment, however small, is unacceptable as it significantly limits the turbines ability to run full power.

That noted, and owing to the likely consequences, shaft alignment needs to be highly optimized, a lot of resources, material and time, have been put on their engineering design improvement. The reason is that once alignment has been achieved, it becomes the function of the bolt is to hold it in that position at which it was set.

Copyright:

ebitularmbert

Copyright:

ebitularmbert

And this is important given that at some point, if for some reason, you have to take the bolts out, and disconnect the shaft, you obviously want it returned back to where it was before, having already spent a lot of time and resources in getting that alignment right the first time.

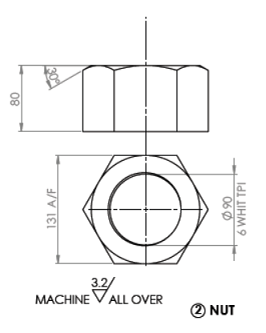

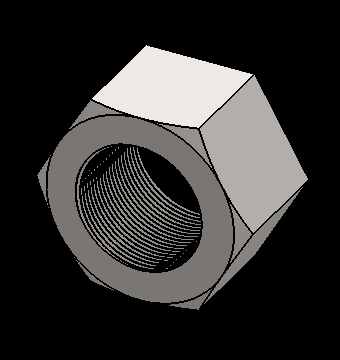

The Nut: Copyright:

ebitularmbert

The Nut: Copyright:

ebitularmbert

The standard through bolt has been the common bolting solution decades, and still is popular. In deed, they are the ones most of us are familiar with.

Relatively cheap, and readily available, with them, you only have to insert the bolt through the bore after which you tighten with nuts on either side. That way you effectively create a friction connection.

The disadvantage of this is that the amount of the torque transmittable through friction is one, significantly limited. Two, excess torque easily leads to costly slippage and in deed misalignment.

These result in micro movements as well as uneven loading, which in turn lead to the damaging of the bolts and bores. This comes to necessitate the rebuilding of the shaft and reestablishment of the alignment.

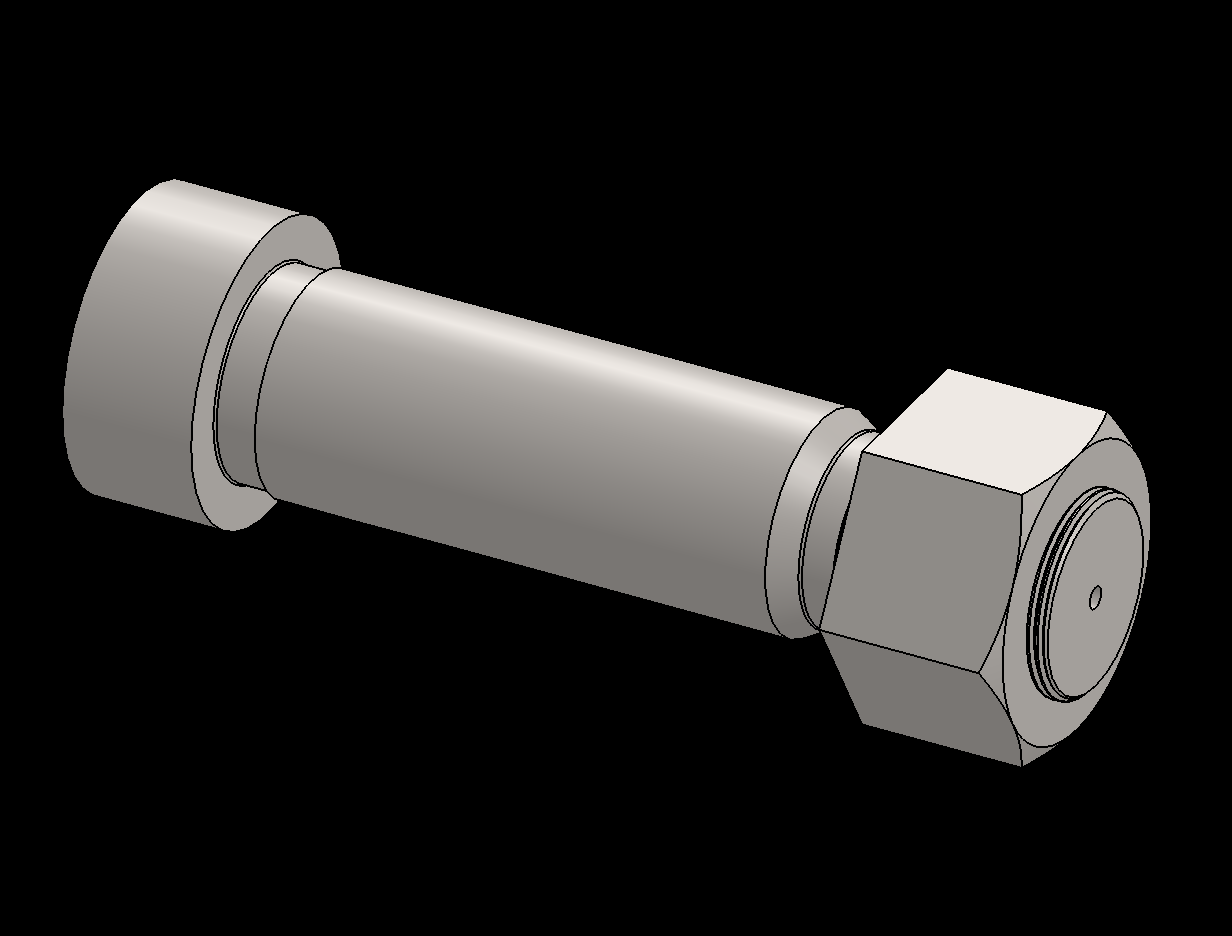

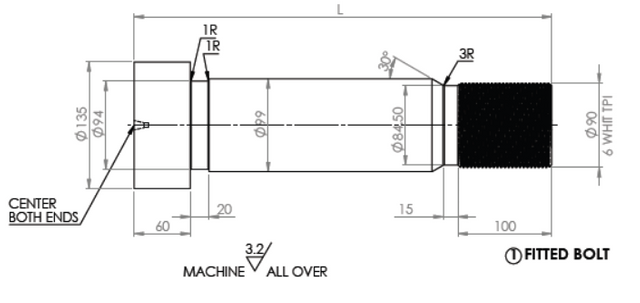

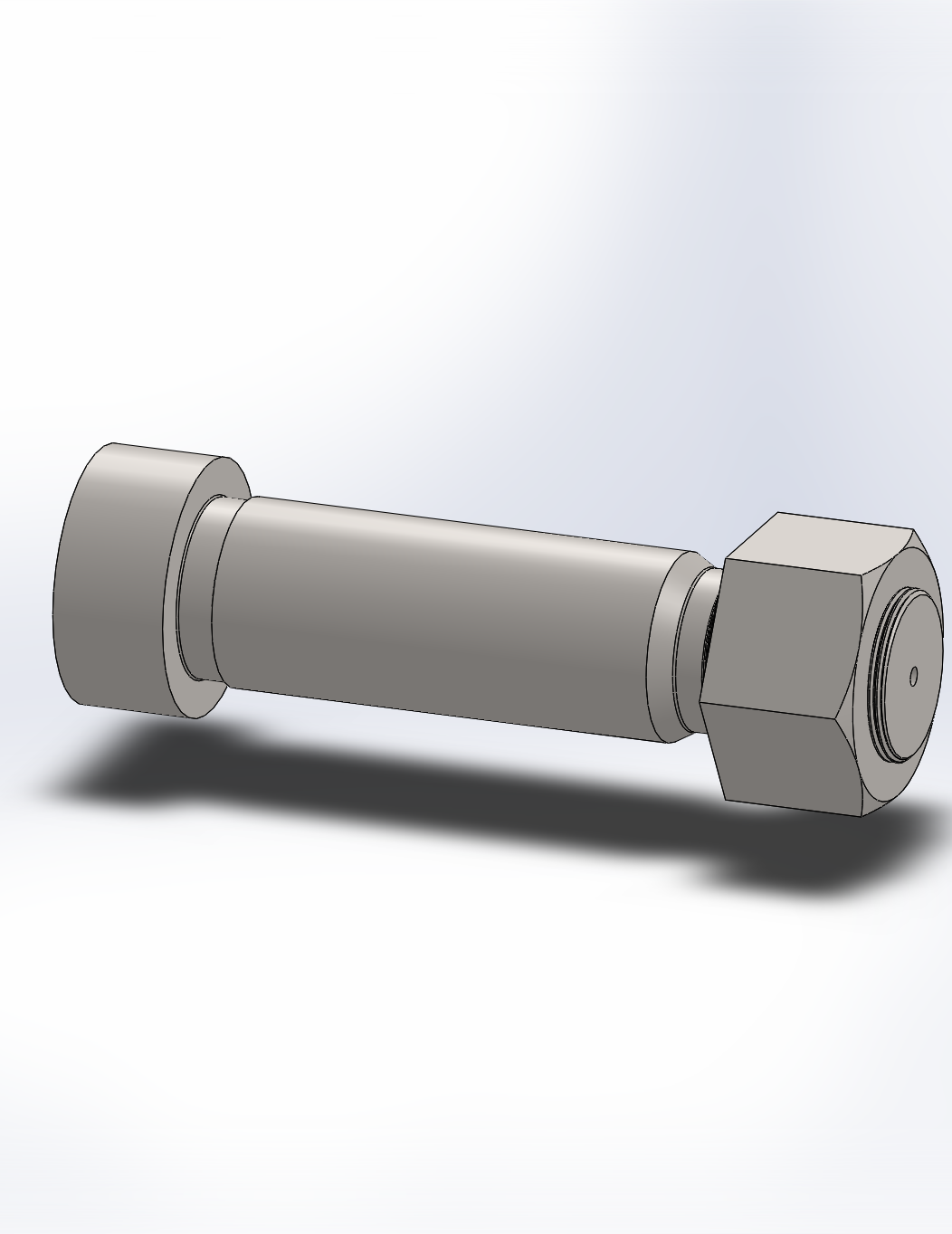

The Final Design product: TURBINE SHAFT FITTED BOLT

Others to next features

Fitted bolts. These fill the bore, and in theory offer a torque capacity that is much greater because the torque is driven through direct shear and across the bolts cross-section. In practice however, achieving a well fitted bolt is very difficult, because its diameter reduces the more it is tightened, thus creating a gap between the bolt and the bore, and resulting into similar slippage and bolt failure problems.

Expanding sleeve bolts come handy under such shortcomings. These expand into the bore thus ensuring a well fitted bolt and evening load distribution. Unnecessary movement and slippage are effectively eliminated, making sure that any such shaft alignment is reestablished automatically after reinstalling the sleeve bolts.