Main Methods of oil Extraction

The oil is composed of a mixture of organic materials, especially hydrocarbons insoluble in water. It is produced in the interior of the earth by means of a process of transformation of the organic matter coming from sediments and that accumulate in geological traps that are formed in a natural way.

The processes used for oil extraction depend to a large extent on factors such as the location of the deposit or the characteristics of this deposit. Once an area with the presence of oil has been detected, a certain depth is drilled to reach it, in some cases these perforations can be up to 6000 meters.

The process of drilling and extraction is usually simple. A type of cannon is introduced and lowered and the casing is drilled just at the point where the bag was detected. The usual thing is that the oil flows through the holes that have been made and can be extracted by a pipe with a smaller diameter. To this pipe of the denominates pipe of production.

There are two situations:

That the deposit has its own energy that is usually generated by the underground pressure itself and by the elements that usually accompany oil such as gas and water. In this case, the oil comes out by itself at the time of drilling. What is usually done is to install in the upper part of the well a device called Christmas tree that is composed of a series of valves that serve to regulate the passage of oil.

In case the deposit does not have its own energy, specific extraction methods are used. The most common method is the rocker arm through which, through a permanent swing, a pump is activated at the bottom of the well that sucks the oil to the surface.

Generally, the oil extracted from the wells is usually accompanied by sediments, water and natural gas, which means that the environment must first be conditioned to produce, separate and store these products. In these processes, it uses as many elements as possible, which is why the elements that are separated from oil, such as natural gas, are used to send it before treatment to the consumption centers through gas pipelines.

The purified oil is transferred to storage tanks and to oil pipelines that transport it directly to refineries or export ports. It is important to know that you can never take advantage of 100% of the oil contained in a deposit, in fact, the maximum amount that is usually used in these deposits reaches only 50% or 60%.

How they do it - Extract oil - DiscoveryMAX

Extraction systems

Let's now analyze the main systems that are used for the extraction of oil in a field. The only way to know if in a place where there is expected to be oil there is, is through drilling. The first drilling that is usually carried out is called exploratory drilling and its purpose is to confirm if there really is oil in the deposit.

The most used methods to achieve oil extraction are the following:

Percussion method.

This method is already almost in disuse and consists in the use of heavy trephine that together with a reference rod increases its weight. This bar is fastened with a steel cable connected to a rocker arm. An alternative up and down movement that is driven by a motor is transmitted through the rocker arm. With some frequency, the trephine is removed to remove the materials or detritus using a tool called a spoon.

The great disadvantage of this method is that it is a very slow process and this makes it use less and less. In fact, its use is made only in very small deposits.

Method in rotation.

This method is somewhat more complex than the previous one because by means of the trepan that is hollow, it is screwed to a series of steel pipes that form what is called the sounding bars. These bars rotate driven by a rotary table located at the base of the tower and which is linked by a chain transmission with the motors of the control panel.

The so-called rotary table has a square hole in the center in which a drilling column slides down as the trepan advances. In the highest part of the tower there are rigs that make it possible to raise and lower the equipment. It is precisely the movement of the rotary table that makes the drilling work. When necessary, new probing rods are added and screwed in and measure around 9 meters.

This method is the most used in the majority of reservoir operations. This described operation is repeated as many times as necessary. Due to the movement the debris crawls to the surface.

Once the drilling has been carried to 100 or 150 meters, the well is poured through a metal pipe and quick-setting cement (cementing process) so as to avoid landslides due to leaks from the water layers that are usually traversed .

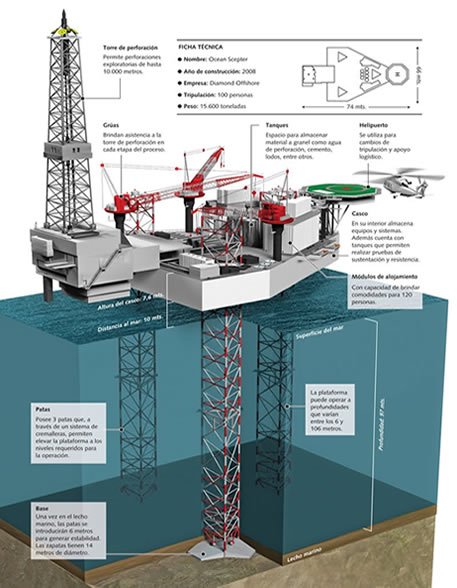

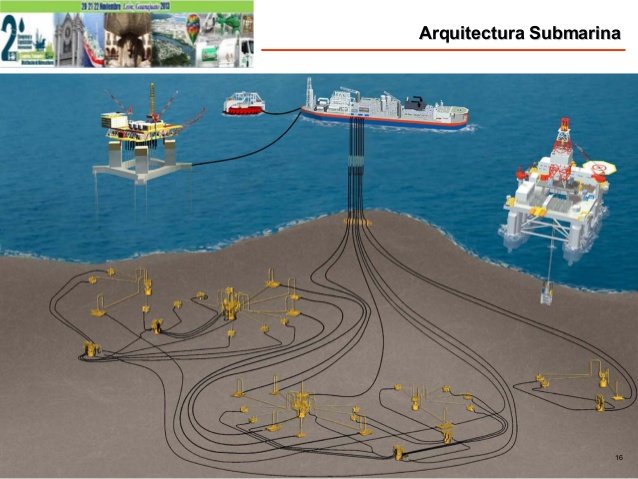

Underwater drilling

In many cases, in order to take advantage of larger oil deposits, excavations and drilling are done on the sea. These are equipment that is installed on a platform located far from the coast in depth waters of up to several hundred meters. There are different types of platforms, some are floating and others are anchored to the seabed on stilts. These second ones resist well to the waves and the wind, as well as to the ice.

Regardless of the methods used for the extraction depending on the materials and the area, the most suitable materials and drilling equipment are usually chosen.

Here you have a summary of the main systems used for the extraction of oil, but there is undoubtedly a whole world to discover associated with this product and that we will be revealing.

Methods of drilling and extraction of hydrocarbons

Images Source :

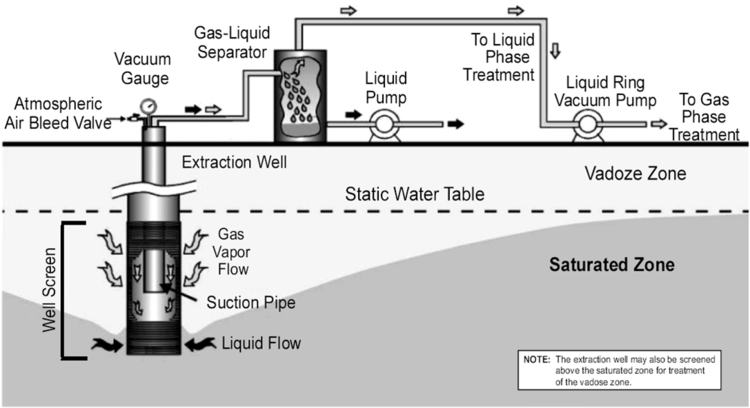

http://gidahatari.com/ih-es/procesos-remediacion-aguas-subterraneas-ambientes-baja-permeabilidad

http://oncubamagazine.com/economia-negocios/petroleo-en-cuba-cambia-la-dinamica-inversionista/

https://www.lacomunidadpetrolera.com/2013/11/extraccin-del-petroleo-aspectos-bsicos.html

https://es.slideshare.net/LTDH2013/sesin-tcnica-sala-fpso-arquitecturas-submarinas-y-sus-principales-equipos-y-ductos-para-la-explotacin-de-hidrocraburos-en-aguas-profundas-y-ultraprofundas

Source:

http://www.ingenieriaquimica.net/articulos/395-principales-metodos-de-extraccion-del-petroleo