The art of creation: The Manufacture of bottling machine member

Let us make this simple assumption.

Today you are going to be the manager of a big company like coca-cola in a branch where your sales are brightest. this means you would have to manage a big factory with big equipment and machines. But after few weeks of smooth operation, you got a report about a damaged part of your bottling machine and it no longer functions properly.

This is going to be a very big headache because you probably didn’t think something like this could happen. Of course, it would be outrageous to replace the whole machine because of a simple part that was damaged. So, you pick up your phone to call a maintenance engineer to give the order to fix the machine.

This is the dilemma Mr. Tunde the manager of a popular company that produces drink finds himself this morning as his maintenance engineer (Mr. Owolabi) just told me how he had collected a huge sum of money from him. he lied he had to import the part from another country and to fast-track it, he would have to pay extra to get it here in time.

He was eating a bucket of chicken and drinking a chilled bottle of yogurt as he was explaining this to me at our workshop which is just 5 streets away from the company he worked. of course, he had paid for the machining of the part he told his boss he was going to import.

Have you ever wondered how he got that part that was damaged or how machine parts are created? do not be like Mr. Tunde who was so ignorant he didn't know how parts could be machined anywhere.

well, here is how we reproduced his machine part but first let me describe the mechanical part.

The mechanical part

The mechanical part to be reproduced is a part of a bottling machine used in corking or sealing of plastic bottles by a popular company in my neighborhood. it is circular and made of stainless steel which has a female thread inside (this means it was disconnected from a male part before being brought to our workshop). The male and the female part could simply be compared to the human sex organs the male part should fit directly into the female part without any issue a good example s your nut (male) and bolt (female). so, our machine part has a female part threaded on it.

This mechanical part is a vital part used in the bottling of drinks as it covers tightly the cover of the bottle without the human help. The mechanical part is damaged as it has expanded beyond the size, so it no longer cocks the bottle. It has a threaded part, a chamfer, and holes drilled on the side.

Reproduction of machine part

In the reproduction of “what looks like simple” machine part, there are certain machines you need to know about in manufacturing process. Some of which have been discussed extensively by our steemit mechanic @rharphelle. you can read it up here. The machines used were

The lathe machine and the milling machine

The milling machine is a very important machine tool used in machining and manufacturing of parts. It is capable of several operations which I can’t list right now but you would see some along the way.

I remember an exam I did at my undergraduate level in which we were asked to list 48 operations that can be done on a lathe machine. Are you surprised? Well, don’t be the lathe machine is really a kind of multi-operational machine.

Tools used in the reproduction of part.

- A stainless steel bar

- Machine tools used on the lathe and milling machines.

- Spanners used to control the tool post

- Caliper

- File

The operations and steps took to reproduce the material

After getting the stainless-steel rod either hollow or non-hollow the stainless would be bigger than the actual component both in length and in width. In our case, we were able to get a hollow stainless rod.

Note: This is after taking the measurements of the parts with the caliper.

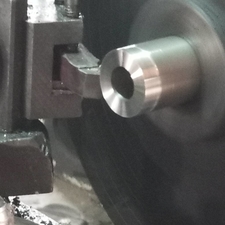

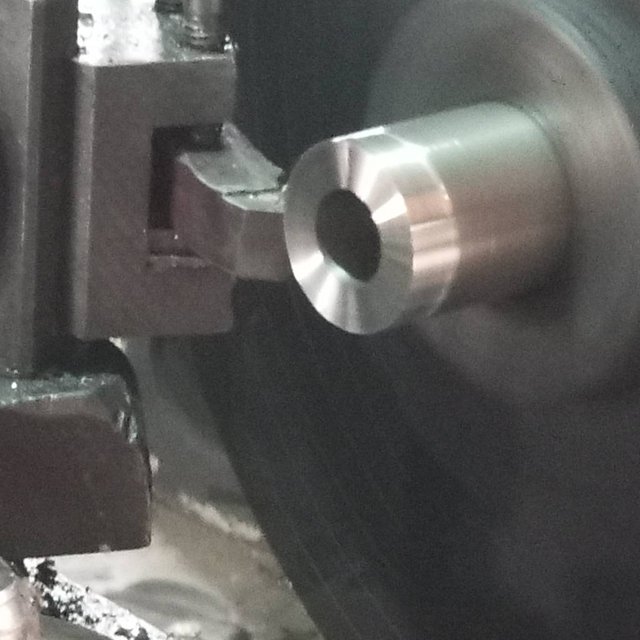

The rod was set on the spindle (i.e. I ensured it was straight as you don’t want your work wobbling, it would not give the part intended if not properly set). The first machining operation carried out was facing

Facing operation.

The facing operation requires you setting your facing tool on the tool post and allowing the workpiece to rotate at a comfortable speed set by you on the headstock. As the workpiece rotates, the tool post is moved to meet the tip of the material as the head of the workpiece is chopped off to give a polished and neat surface.

The turning operation.

The turning operation requires you to reduce the diameters of the cylindrical bar by feeding the tool post at the side of the rotating workpiece. This operation needs to be done gradually and not at once. Rushing this could lead to you damaging the tool piece or give room for too much friction which can lead to very hot metal chips flying everywhere.

The facing operation is carried out with the facing tool with the speed controlled as desired by the machine operator

After carrying out the turning and facing operation you should have a smooth and shiny end of the stainless steel facing outside. You can proceed to groove.

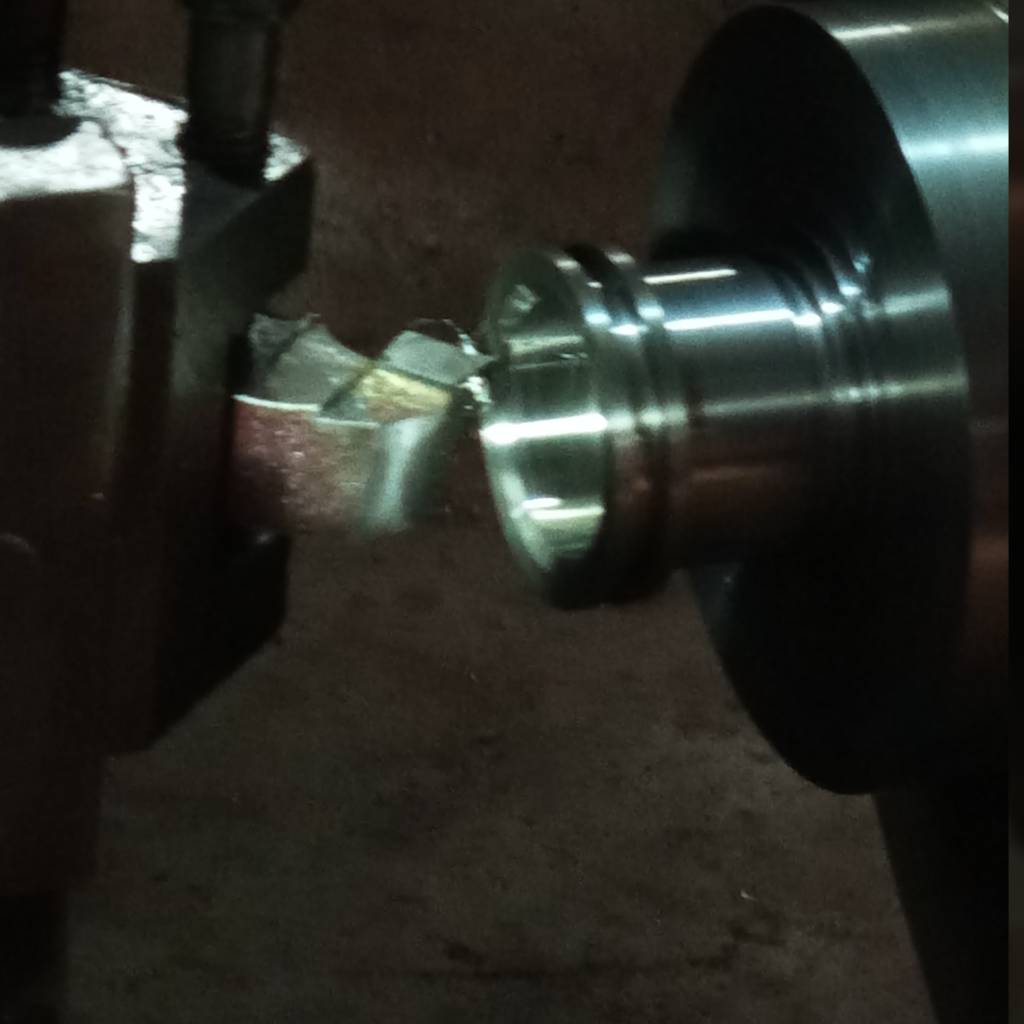

The grooving operation

The grooving operation is like making a path in the red sea, just like Moses did the water on both sides and the men walked along the groove. The operation involves having some parts taller than other parts on the same cylindrical surface (i.e. the diameter of a part is larger than another part)

This operation was carried out using the grooving tool which was fed carefully with its pointed end reducing the areas measured.

The boring operation

I hope this is not BORING? well, that is not what I mean (by that term I mean making a hole), although my job could be boring. lol

The boring operation requires you to expand the already hollowed workpiece to the internal diameter measured from the original piece. Our original workpiece had two different internal diameters so we started out by reducing to the thicker diameter first and then taking down the part with the lesser diameter using the boring tool.

All these measurements were done using the vernier caliper or else one would have made mistakes and this replica isn’t going to be a replica after all.

The chamfering operation.

After carrying out the operations above you would discover that the edges of these metal part are sharp and could cut or prevent the cover from entering in the part. Which would either lead to an accident or damage your materials (plastic covers).

The operation ensures the safety by smoothening the edge with a tool, it is usually carried out with the tool turned at an angle to the workpiece. This tool takes out the sharp edges and makes it look curved just like how mobile phones shapes are.

The cutting operation

The workpiece was removed from the spindle and was placed on a vice before using the hacksaw to separate or cut the machined part from the other part. After cutting the part was placed on the lathe machine for facing and chamfering operations, in preparation for threading.

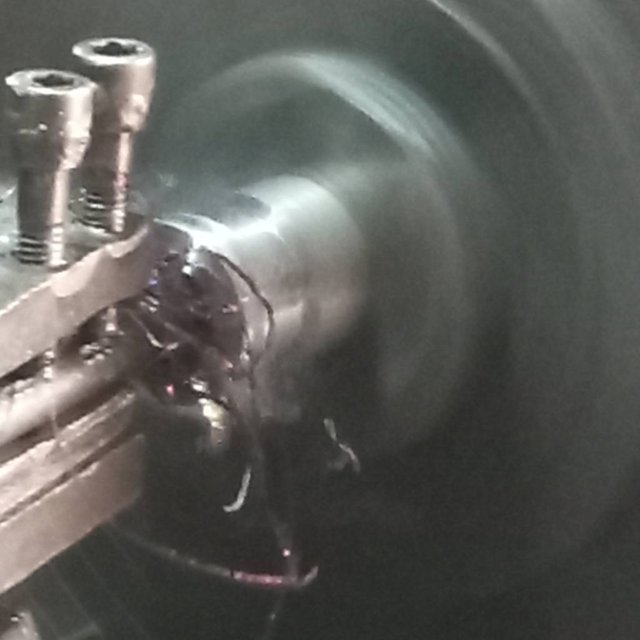

The threading operation

This operation is responsible for the creation or manufacturing of the nuts and bolts. To carry out the operation on the lathe machine, the thread pitch on the original material were first measured by the operator and a male part just like the nuts was created especially for it then the threading of the machine part began.

It ended with the filing of the thread to prevent accidents from happening and to smoothen the engagement between parts.

The filing operation

The filing operation is carried out either to reduce the size of the material slightly or to smoothen the surface of the stainless just in case there is any little lump or bump that could pierce into the holder’s hands.

This operation was done after carrying out every operation listed above. The operator held a sandpaper or a file and using it while the spindle was rotating the workpiece. You might want to be careful while doing this because you could end up going away from the tolerance range.

After the filing operation, the replica of the part is almost done and it is just left with a little operation which was carried out on a milling machine. We used the milling machine.

The drilling operation on a milling machine

The part was stationed on the table and tightened to prevent it from sliding off or shaking during the operation and the drill bit size of 6 inches was connected to the milling machine spindle which was then used to drill out the holes in the replica.

like I mentioned earlier, I used the file or sandpaper to smoothen out the edges of the drilled hole. After this is done, we have an exact replica of the part which would carry out the same function as the original part that was damaged earlier.

Watch this video I made below to see how some machining operations were carried out.

Image gallery

Conclusion

In the real world where it takes months to order machine parts and get them shipped down only to discover that the machine parts wouldn’t work or there has been a mistake in the recreation. This is why manufacturing engineers are everywhere to help you get that spare part you need to get it your company or machines working effectively.

I was able to do this with this machine part and the customer was happy. He called me later telling me about how the part functioned. This is how machine parts are created and are made, they are not all cast or forged but some are machined.

Do not be ignorant like Mr. Tunde instead be smart like Mr. Owolabi who knows how materials are being machined to form spare parts for big machines.

I am glad you liked this post. Feel free to drop your comments.

References

For further readings about where i got informations from follow this links or get these books

- lathe facing operation

- machining handbook

- lathe operations; chamfering

- grooving on lathe

- high speed drilling

- Machine Tools - Dr. R. Kesavan

All images and videos were taken and made by me and are products of the infinix zero 5 camera.

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

I am not a machinist, but we're lucky enough to have one who helps out in my lab with small custom jobs. It's mesmerizing to both watch him lathe and all the little tricks he uses to get measurements just right.

Yeah.. Its not easy to be a machinist you have to be perfect and stay within the tolerance otherwise one could just be wasting materials and time also.

Amazing stuff @adetola am quite familiar with the lathe machine. That's great skill bro maybe I should come and be your apprentice lol 😁 😁

Lol... I am still learning how to become a pro on the lathe machine. It takes a lot of time.

After scanning through your gallery, perhaps we should call you steemSTEM mecho!😁... Just saying.

Thumbs up for always giving us original content!!!

Lol... I am glad you found this interesting.

Machining is a very fundamental part of Engineering. You just reminded me of all I was thought about the Lathe.

During my internship, the company eventually got its own late and resident operator. But before then, transporting materials to and from the machining workshops made my job more complicated.

Is this stainless steel?

Did you have any difficulty in processing it?

It is not pure stainless steel.. It has been mixed with other forms of metal.

How do you plan to fight corrosion?

The metals are coated.. And the composition of these metals should prevent them from corrosion. One good thing about the lathe is the coolant it can help prevent corrosion. I would be discussing it soon.

I asked my question, because you did not write anything about the cover. Did you cover the object with chrome? Have you used the electroplating method?

Machining has really aided in the replacement of parts. You did well to share your real life experience in this respect with us, letting us know the problem and the solution and then how you went about the entire process.

Well done sir!

Thank you sir.. Your presence here is highly appreciated.

Its pleasure for me.

This is a very detailed post on machining. And the video you provided spiced up the entire post :)

Nice piece bro. Keep it up

Thanks my boss... I am following your path.

wow

Its amazing right?

yes boss