In the shop with Silverd......part 1

Evening all......

It’s been quiet a while since I posted any of my work, been crazy busy catching up.

So I was thinking that instead of just showing you the final product, I’d show you what goes into making that final product.

Today I had to make the drawers for my current job. All of my drawers are always done with a dovetail joint. Depending on how high end the job is they will be either routered with a template, or 100% hand cut.

Today I will show you hand cut dovetails

Here are the tools necessary to do the job.

I’m going to briefly explain the process and show pictures. There is way too much information for me to do a complete step by step. But I thought you would enjoy this.

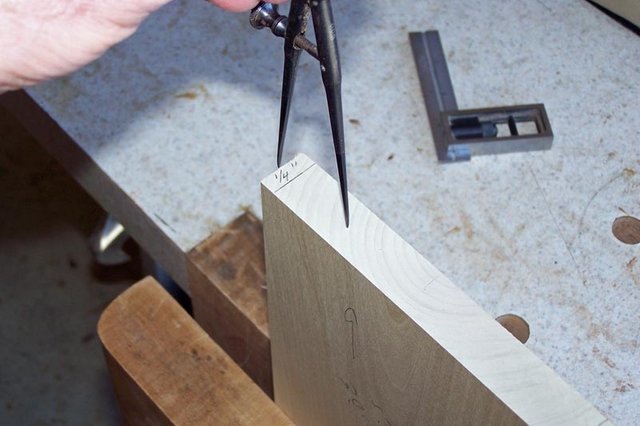

The first thing you need to do is decide the size of the dovetails and evenly space them out. All my drawers for this job happen to be the same height so I only have to set the caliper once. On jobs with several different height drawers I use multiple calipers to speed things up.

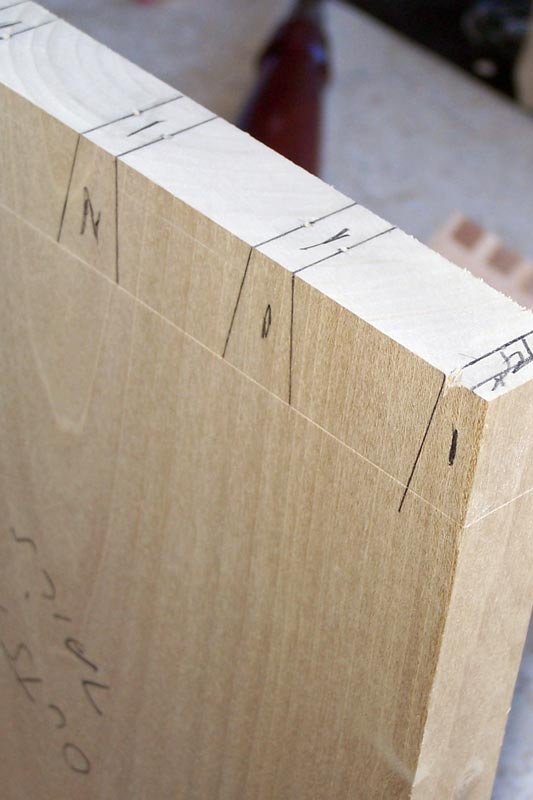

Once you determine the size of the dovetails you mark your boards.

Now it’s time to cut.

To do this you use a stiff thin blade dovetail saw. The teeth are super fine and extremely sharp. There are 15 teeth per inch on the saw you see in the picture. When you cut you need to ensure that you stay directly on the line.

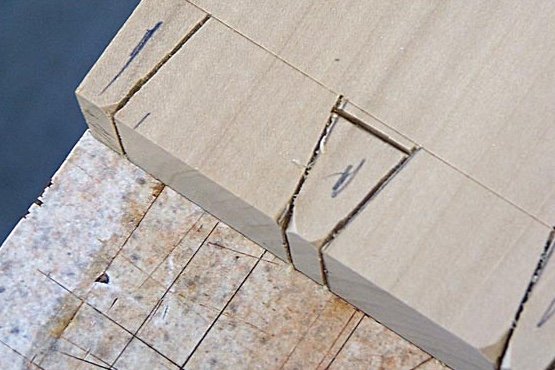

Once you make all of the cuts, you then have to chisel them out. This is by far the most important part. Your chisels need to be 100 flat and extremely sharp or they will destroy your work. Splintering, checking and actually splitting the wood can occur with improperly honed chisels.

Note* I couldn’t take picture of me chiseling.

Now that the male side of the dovetail is done, we need to mark the female side using our piece as the guide. This ensures a perfectly snug fit. You use a marking knife for this.

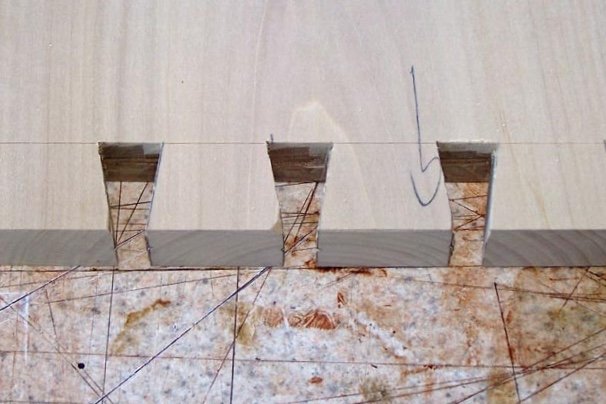

Now back to cutting

To ensure a tight fitting joint you cut these pieces just inside the line. You can always lightly chisel the piece to remove any high spots.

Now it’s time to test fit the joint......

What a beautiful fit.........

Hope you enjoyed this post, I’m going to try and work more of these into my posting.

If there is something specific you would like to know how to do. Please ask and I’ll see if I can do a post on it.

Thanks for stopping by.....

That is some serious skills and I love handmade things and this is such a beautiful work and if it was me 😜 the fit wouldn't fit so well 😂 hahaha

Wood is the best thing to work with, wish I had the skills but I love watching things like this.

Thank you for sharing.. Beautiful!

🤗💕🌹

Posted using Partiko Android

Mad skills bro!

This post is supported by @tipU upvote :)

@tipU voting service: instant upvotes | For investors.

Damn man! Very impressive skills — that joint is fucking Egyptian!

👊😃

Thanks man. Its just part of my shop life. Crazy tging is I ended up deketing alot of the post because i thought it was too long. The tools in the first picture is worth about 4K. No one would ever guess that.

That’s a whole different level of carpentry (and tool$) from what i know... 👊

No worries, I’ll be your craftsman.👍

Sweet! I’ll cut the 2x4’s in the back of the shop 😜🤣😂👍

You have skills so i bet i could teach you a lot.

GET TO YOU PO BOX!!!!!

I would love to see you work and have you explain what you were doing... i’m pretty good with fitting mitres to about 1/32 (or 1/16th rather 😜) and making things plumb/square/level, but the work you do is way outta’ my ball park.

Going past this morning... they open in 40mins

😎👍

Mad skills brother, truly impressive...

This post brought back memories of my Dad doing Carpentry or is it Joinery in the shed, thanks for the wonderful memories

It’s considered both my friend. Glad that it brought back memories for you. I’ll be doing more of these as I get time.

MY dad was amazing with his hands in so many ways, and looking forward to more posts like this which I am sure will trigger a few more nice memories for me :)