Energy through the Ages: How Steam Power Changed Manufacturing

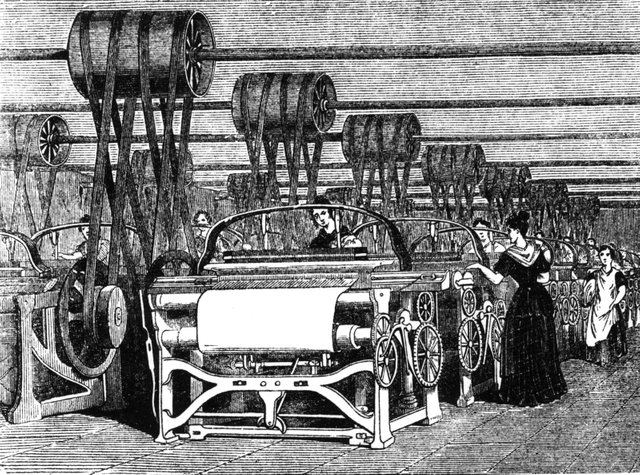

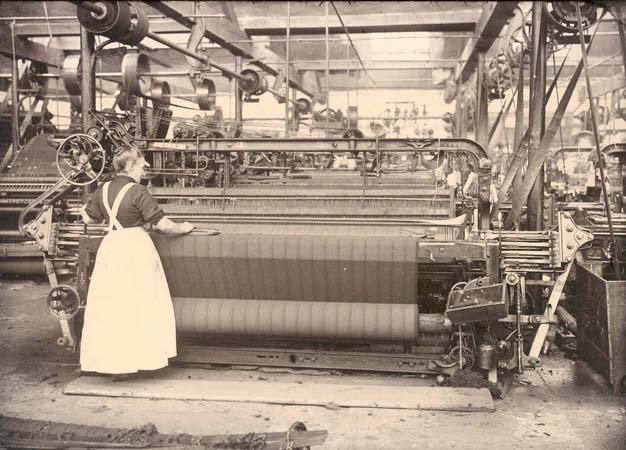

In the 18th century, textile manufacturing was among the first industries to benefit from industrialisation. The first power looms began appearing in the late 1780s and automation took off rapidly.

Fruit of the loom

Edmund Cartwright, a Church of England minister with little engineering training, pioneered the use of machinery that used a loom with a drive shaft to turn thread into cloth.

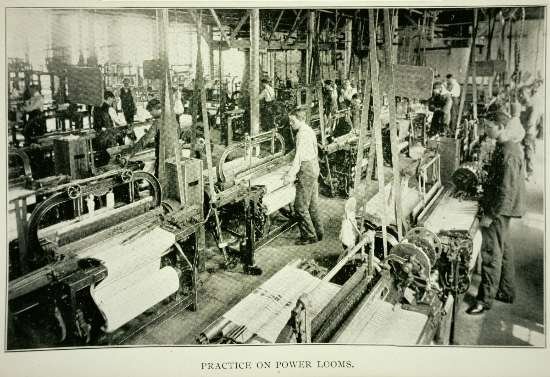

His first attempt was slower than standard hand looms. But by 1778, his machine had improved so much that it performed the three main processes of weaving – shedding, picking and beat-up – with enough speed and efficiency to get mill owners’ attention.

Mill workers were outraged at the use of powered looms, seeing them as a threat to their jobs. Some retaliated by burning the factories down.

Cartwright built a mill stocked with his new looms. He first tried using cattle to power them, then water, before he harnessed James Watt’s steam engines to increase productivity. He also invented a wool-combing machine that could do the work of 20 hand-combers, with the potential to save manufacturers more than £1,000 per annum.

Cartwright eventually went out of business, but his inventions came into general use in the early 19th century. In 1803 there were 2,400 cotton power looms in Britain. By 1850, there were 250,000, of which almost 177,000 were in Lancashire. They provided the basis for Manchester’s textile boom. Additional improvements were made to looms by other inventors, notably William Horrocks, making the machines increasingly more efficient.