How large companies operate with a global supply chain - IKEA in depth Case Study

IKEA are a global home furniture company who specialise in producing large quantities of flat packed furniture. A pivotal attribute that has been detrimental to their success is there global supply chain. A ‘’Supply chain process is a flow of activities with the goal of meeting the requirements of a customer. It includes all internal functions, logistics, distribution, sourcing, customer service, sales, manufacturing and accounting.’’ (Nahla, 2017)Without fully integrated systems all working together in tandem effective and efficient operations cannot occur.

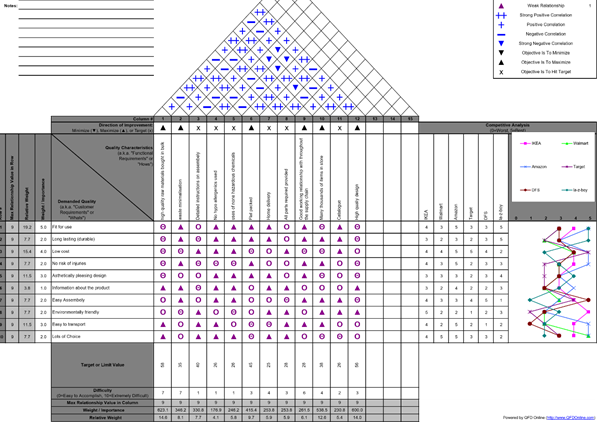

A house of quality diagram is used to by companies to understand if their product is living up to customers’ expectations. It is used to compare and contrast the relationship between customers wants and needs too the organisations production capacity.

The house of quality diagram shows that the three most valued attributes too IKEA customers for their products are; that the products are ‘fit for use’, have a ‘low cost’ and have an ‘asthetically pleasing design’. Too assure that these important customers’ requirements are met IKEA themselves assure that ‘high quality raw materials are bought in bulk’. This helps them keep the costs of their products down due to the discount factor provided from buying in bulk. Furthermore high quality raw materials help make sure that finished products are fit for use. IKEA’s massive stores and flat packing of products allow vast quantities of products to be readily available for customers. This gives IKEA large economies of scale and there for are able to provide their products at a low cost to the customers. High quality materials used in the products of IKEA’s and extensive investment in product design assures that customers are able to receive the asthetically pleasing product that they demand.

In comparison to IKEA’s main furnishing competitors on average IKEA are the best at meeting their customers’ needs and wants. One area that needs improvement however is the durability of their products. One possible reason for the lack of durability of their products is the fact customers self-assemble their products. This means that there are more variables involve with the quality of the finish product e.g. did the customer uses all screws and bolts to assemble their product or maybe they took shortcuts whilst building the product.

From the house of quality diagram it can be inferred that there is a strong positive correlation between flat packing and home delivery, as well as between flat packing and the stores being able to store many thousands of products. This is because flat packing minimalises the space required to store each product, as flat packing makes the products easily stackable. On the other hand there is a strong negative correlation between bulk buying raw materials and waste minimisation. This occurs due to the fact when bulk ordering ‘Bigger volumes mean lower prices.’ (Anon, 2017)Therefore there may be some left over raw materials, however this probably is a huge problem for a company such as IKEA who have many thousands of products. This is because excess could be used to manufacture another product.

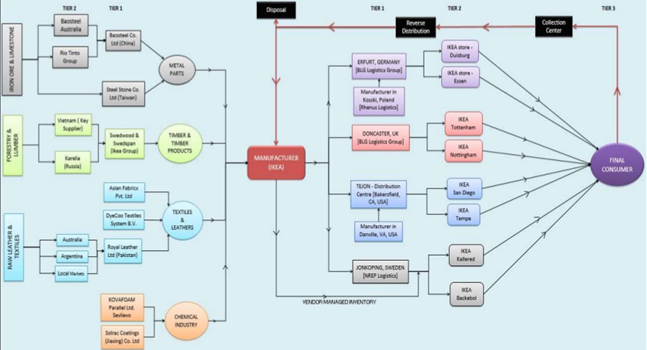

The supply chain for IKEA is very complex with hundreds of companies involved in every step of the way from the collection of natural resources to the finished products. Along the way there are many phases involved before the finished product reaches the consumer. IKEA has a strict code of conduct involved with purchasing from certain suppliers called the IWAY code, which is a set of protocols aimed at reducing waste and industrial impacts on the environment.

In the primary sector IKEA aim to develop raw materials from natural resources, which then can be used to manufacture products. IKEA source the raw materials from many different companies in a range of countries. IKEA’s three most used natural resources are metals, wood, textiles and leather as well as chemicals used in the production process.

)

)IKEA sources most of its steel products from Baosteel Co LTD who obtain the raw materials used to manufacture their steel from RioTinto a British-Australian mining company as well as their own subsidiary mining group Baosteel Australia Mining Company LTD. Collectively ‘’Baosteel imports 1 million -1.5 million mt of coal annually’’ IKEA choose Baosteel due to the high quality products they provide which enable IKEA to conform with their safety protocols on their products, furthermore in 2012 Baosteel passed IKEA due diligence which enabled them to supply stainless steel for export only to IKEA’s suppliers, this is due to their green manufacturing process.

However, Baosteel aren’t IKEA’s only metal supplier. They also source metal parts such as nuts, bolts and screws from Steel Stone Co. LTD in Taiwan, these products are high quality however they chosen due to their low cost as there is a low cost of labour in Taiwan.

IKEA is one of the largest consumers of wood in the world. IKEA have their own subsidiary company to handle the production of their wood based furniture called Sweedwood. In its attempts to conform to IKEA’s own IWAY code Sweedwood has its own sustainability plan for all the wood it uses. Sweedwood has over 15,500 employees working in offices and factories around the world.

!

IKEA sources a lot of its wood from Vietnam, drawn in by cheap labour and natural resources. On the other hand in the Karelia area in Northern Europe has a very fragile eco-system and IKEA’s decision to source wood from there puts a lot of responsibility in their hands. Furthermore IKEA doesn’t accept wood that has been illegally logged and supports 13 WWF projects. IKEA’s ‘wood’ products are particle boards, all are produced in one factory in Southern Sweden called Hultsfred. Where wood is turned into saw dust which in turn is converted into particle board planks.

IKEA’s sources the majority of its textiles and leathers from Europe and Asia respectively. The majority of the volume of textiles produced come from within South Asia. A small town in India called Kurur is home an Ikea supplier called Asian Fabrivx’s factory, only a few hours away from Tuticon a port that ships to European shores. Furthermore, IKEA agreed Royal Leather limited as its supplier of finished leather in 2012 who’ve imported modern machinery from European countries. Royal Leather was due to its ‘environmental and social compliance capacity’. The skins used are ‘a by-product of the meat industry.

The chemical industry is a controversial one, so IKEA aims for all of its products to not use chemicals and substance that can be harmful to people and the environment. Furthermore, the recent EU Reach legislation requires a precautionary approach to the use of chemicals in manufacturing.

One of IKEA’s chemical suppliers are Parallel LTD who are located in Bulgaria. Parallel LTD produce Polyurethane (Kovafoam) and source their production machines from companies in Germany and Italy. The high quality machinery has led to high quality finished products used in IKEA’s furniture.

)

)

Logistics ‘’is the part of supply chain management that plans, implements and controls the efficient and effective forward and reverse flow and storage of goods and services, and related information between the point of origin and the point of consumption in order to meet customers’ requirements.’’

IKEA’s first distribution centre for Central and Eastern Europe Logistics LTW Intralogistics was opened in 1989. LTW are world renown for their innovative storage and retrieval machines which are a lot more efficient than manual labour. Since 1989 LTW have worked side by side to IKEA in 11 countries spanning over 3 continents installing over 220 pieces of machinery.

In 1997 IKEA started a partnership with Consafe Logistics, who have since been involved with setting up their ‘’Astro warehouse management systems’’ in 15 of IKEA’s distribution centres. IKEA choose Consafe for their world renowned integrated manual and automated warehouse management systems.

IKEA’s distribution and warehousing works in a multitude of ways in the aim to improve efficiency. IKEA aim to achieve this through rationalisation and simplifying the distribution process. Not only do IKEA aim to increase operational efficiency in their distribution channels and warehouse storage, they also try to reduce impacts on the environment. One example of this is flat packing products leads less space being used in storage and transport meaning a larger quantity of goods can be packed into one warehouse or lorry, there for there a lower costs of storage and less Lorries needed to transport goods leading to less pollution of the environment from delivering products.

IKEA’s distribution centres work as a wholesaler, they enable IKEA to have storage areas for stores and for purchasing products and resources from suppliers.

BLG Retial Logistics work hand in hand with IKEA in the aim to perfect the organisation of goods at IKEA’s Doncaster site. Their job is to plan transport routes and timings, ensure quality and quantities are upto the demands that IKEA wants. Doncaster is now the largest IKEA distribution centre in the world and can store at maximum capacity 270,000 pallets.

NREP logistics manages IKEA’s Jonkoping, Sweden site, which has total distribution space of 60,000 sq miles. The NREP distribution centre works to ensure the efficient loading and transportation of products, this has been achieved by having separate entrances and exits, as well as large loading areas.

If a customer is not satisfied by the product they receive they can return it to the store they purchased the product from. This means that IKEA needs reverse logistics systems in place. What happens is the store checks which distribution centre the product has come from and sends it back where it is tested. Then the product sent to a Swedish firm where it is recycles and re-distribution. However if the product is faulty and cannot be resold then it is either recycled or disposed of.

!

IKEA’s long term goal is to become and remain the world’s largest home furniture company. But IKEA are not just aiming to achieve this from growing their profitability and market share. IKEA as global company take and manage their responsibility to go about their production and supply of products in a sustainable way throughout the entire supply chain from raw materials to the store. This has been implemented through educating suppliers about the importance of sustainability. IKEA’s approach to sustainability has been a way IKEA has differentiated its self from competitors. This approach could be seen as a clever marketing ploy in the aim to create a friendly and responsible company that can be trusted. Furthermore IKEA’s work with WWF and UNICEF has further promoted the good boy image IKEA attempts to portray to its consumers.

The concept of variation effects IKEA’s supply chain in a variety of ways. Variation is ‘a change or slight difference in condition, amount, or level, typically within certain limits.’ Exchanges rates vary from day today this can be positive and negative for IKEA’s supply chain depending on which currency is being trade and how much the exchange rates varies. This links in to the concept of uncertainty which is defined as ‘not able to be relied on; not known or definite’ this is due to IKEA trading with suppliers and distributors and having to use a variety of different currencies depending on their respective countries. This means every there is variation on what IKEA have to pay their suppliers, workers, distributors depending on the exchange rate. This create uncertainty as if there is a pre-agreed binding trade agreement and there is a hike in price for one currency then IKEA’s pre-calculate profit-loss forecast could be made redundant overnight. Furthermore there can be variation between tastes in different counties this means IKEA need to invest into marketing to assure they are offering the right products to the right people.

IKEA use buffering mechanisms throughout the supply chain, a buffering mechanism is defined as ‘maintaining enough supplies to keep operations running smoothly’ (Smallbusiness.chron.com, 2017). To ensure this they bulk order their supplies so if there is a shortage in the supply chain they often have excess too rely on from previous orders. Furthermore IKEA are driven to minimise waste so they make sure they use all their resources at maximum efficiency. IKEA also uses postponement which ‘’ is a deliberate action to delay final manufacturing or distribution of a product until receipt of a customer order.’ (Management et al., 2017)’ IKEA uses postponement to ensure operational efficiency, this mechanism allows them to know if there is a market for the product and if so a rough estimate into how large the demand for the product is.

‘’All IKEA customers have the right to healthy products. That is why all our product types are tested to and must comply with strict legal requirements.’’ (IKEA, 2017) This has led to IKEA having to adopt new technologies. For example some extremely popular fire retardants have had calls to be banned due to their possible negative health effects such as cancers and birth defects. IKEA have invested into a non-toxic equivalents.

)

)IKEA’s waste ambition to minimise waste links into the idea of sustainability. Sustainability is defined as the ‘’avoidance of the depletion of natural resources in order to maintain an ecological balance.’’ Dictionary.com. (2017) Furthermore IKEA believe sustainability is extremely important and this idea is seen throughout the supply chain. For example IKEA are very cautious of disrupting the biodiversity of Karelia area of Northern Europe or the fact that the support 13 WWF projects.

IKEA’s flat packing of goods for transport has influenced their logistics choices. It has enabled IKEA’s transportation of goods too be highly efficient. Furthermore it also has enabled them to store vast quantities of goods in their stores which allows their customers to have a range of products ready to purchase. Flat packing of goods allow customers to easily be able to take home products which may hold back other home furnishing stores sales due to prebuilt furniture being bulky and therefore hard to transport.

IKEA truly have global supply chain, for it to work like a well-oiled machine they have to ensure that; the complex web has too have efficient and effective logistics behind it. Their relationship with suppliers is pivotal to success. What makes it even more complicated is that IKEA being a global company they possess an ethical and environment responsibility to work in a sustainable and fair manor. Too ensure this they set requirements for their suppliers to ensure they have a safe work place and aren’t endangering the environment or their workers. One of the leading factors to IKEA’s success is the flat packing of their products for transport and sale. This allows them to maximise the available space allowing them to create huge economies of scale. However an efficient and effective supply chain is only the base for a successful company. IKEA have invested heavily into marketing to ensure they are seen as the ‘’good guys’’ and this isn’t just a marketing ploy, they have backed it up with extensive regulation throughout the supply chain. For example they make sure there are no hazardous chemicals or hypo-allergenic used in their products. Overall IKEA’s supply is the base of their success, without it their marketing campaign would have little conviction. As well as this their finance’s would suffer without its as they would be very inefficient with their transport, therefore they would have smaller economies of scale leading to a fall in profit margins.

Bibliography:

Anon, (2017). [online] Available at: http://www.staffs.ac.uk/schools/business/resits/postgrad/InternationalSupplyChainMgmtIKEACaseStudy.pdf [Accessed 8 May 2017].

Slideshare.net. (2017). IKEA Supply Chain Mangament. [online] Available at: https://www.slideshare.net/roymanish91/ikea-supply-chain-mangament [Accessed 1 May 2017].

Smallbusiness.chron.com. (2017). What Is Buffering in Manufacturing?. [online] Available at: http://smallbusiness.chron.com/buffering-manufacturing-31892.html [Accessed 9 May 2017].

Management, P., Cheng, T., Li, J., Wan, C., Wang, S. and York, S. (2017). Postponement Strategies in Supply Chain Management | T. C. Edwin Cheng | Springer. [online] Springer.com. Available at: http://www.springer.com/gb/book/9781441958365 [Accessed 9 May 2017].

Anon, (2017). [online] Available at: http://www.staffs.ac.uk/schools/business/resits/postgrad/InternationalSupplyChainMgmtIKEACaseStudy.pdf [Accessed 8 May 2017].

IKEA, (2017). [online] Available at: http://www.ikea.com/ms/en_KR/pdf/chemicals_and_Substances_en.pdf [Accessed 9 May 2017].

Dictionary.com. (2017). the definition of sustainability. [online] Available at: http://www.dictionary.com/browse/sustainability [Accessed 9 May 2017].

Nahla (2017). Global Supply Chain. [online] Slideshare.net. Available at: https://www.slideshare.net/GhadaAlNahla/global-supply-chain-12538114 [Accessed 12 May 2017].

You see people? You can create an interesting post about literally IKEA!

Great work @co0pz97, but please due to the lack of functionality atm paste direct links to tables and graphs underneath, because they are unreadble.

Cheers man means a lot as I put a lot of time and effort into writing this one up :) @slowo

really great work... respect man...

Thanks man its quite an interesting subject when you look into it!

Well, with your approach, any will be... for sure. Too bad that only few people probably appreciate it, but I could be wrong. That is what I describe as a real content.

This post recieved an upvote from minnowpond. If you would like to recieve upvotes from minnowpond on all your posts, simply FOLLOW @minnowpond

Damn that was a huge post!

Yeah it took me a while to get all the research done and typed up but I enjoyed it!

This post recieved an upvote from minnowpond. If you would like to recieve upvotes from minnowpond on all your posts, simply FOLLOW @minnowpond

Supply Chain is a big problem when it comes to different industries, that's why OriginTrail is here to help them on making the Supply Chain transparent and secured.

https://www.reddit.com/r/Economics/comments/9ygtu6/origintrail_on_agrifood_sector_supply_chain/