I Built a Miniature Water Treatment Plant – Let's Teach Steemit About Creating CLEAN DRINKING WATER

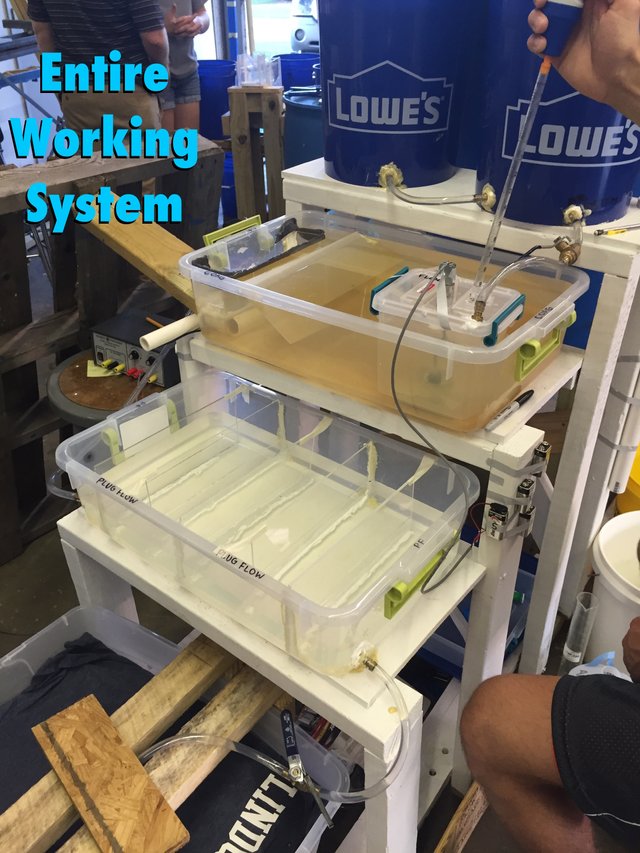

Hey Steemians! It's your resident civil engineer here to teach you about where your clean drinking water comes from! Being able to turn on your tap and get fresh clean water takes a lot of work, and I have built a miniature drinking water plant that will hopefully help you understand.

To begin the project, my team and I began with 55 gallons of incredibly murky river water. The goal was to clean the water of all particles and kill off any bacteria or pathogens. The end product was completely clear and safe to drink water, and here's how we did it.

The key components of drinking water treatment are processes called coagulation/ flocculation, sedimentation, disinfection, and filtration. If you are curious about all of the ways that these processes can be customized in different systems, leave me a comment, but for this post, I will do an overview of how the system I designed works. To get us started, take a look at a video I made walking everyone through the miniature treatment plant.

Coagulation/ Flocculation

The first step of treating the water is to remove all of the clays, silts, and dirt particles suspended in the water. The river water we started off with was very brown, in fact, it was hard to see more than an inch down into the holding tanks. To remove the particles, we added a chemical called Aluminum Sulfate (Alum) which in a process called coagulation/flocculation, which basically causes all of the tiny dirt particles to stick together. We built a rapid mix tank (coagulation chamber) where the water and chemicals were stirred together, which then outflowed into a basin that allowed these formed particles to settle. You can see the rapid mix chamber below.

We hot glued 2 washers to a screw and attached it to a motor. If it ain't broke, don't fix it

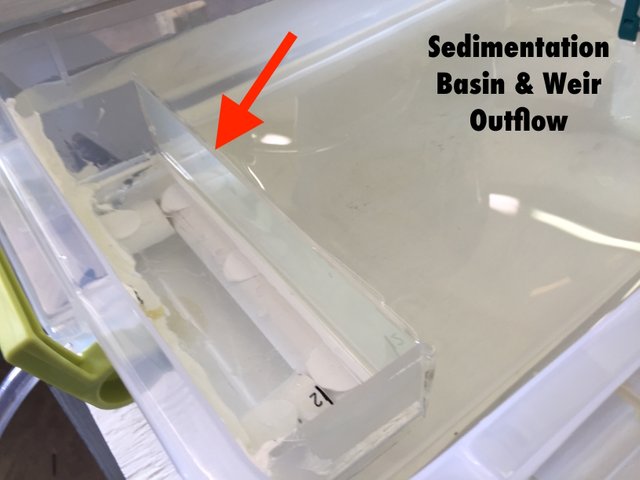

Sedimentation

The particles in the sedimentation basin would very slowly fall to the bottom. At this point, a water droplet would have been in the system for around 2.5 hours. From here, the water would flow over a weir. The cleanest water is on the surface, so the weir made sure that only clean water moved on to the next step. The water leaving this basin looked very clear, and virtually all sediment had been removed from out alum addition.

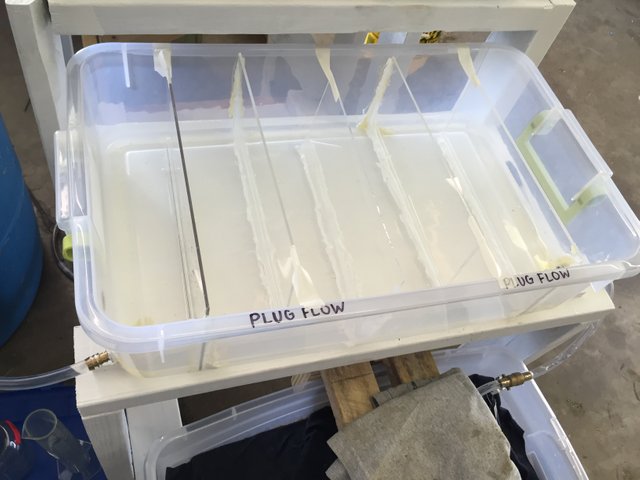

Disinfection

After flowing over the weir, it would travel through a short tube into what is called a plug flow reactor. This is a little bit like a maze, and its sole purpose was to increase the amount of time water spent in the system. We added a select concentration of chlorine, based on preliminary bacteria testing to make sure we killed everything off, called disinfection. Believe it or not, this chlorine we added was just a solution of off the shelf bleach and water, and it is perfectly safe when added in small amounts. If you're in the US, there is likely chlorine in your tap water right now. Water spent about 1 hour in the plug flow reactor where it would then flow to the final step in treatment, the sand filter.

Sand Filter (Filtration)

The sand filter is exactly what it sounds like, a basin with different grain sizes of sand that caught any other particles or contaminants that weren't picked up in previous treatment. Sand filters are used in virtually every water treatment plant as they are the most effective way to clean water.

Disregarding bacteria, you could actually treat water using only fine sand, but you would have to clean out the filter a lot. This is exactly how mountain springs work. The sand filter was by far the longest part of the process. A water droplet would take upwards of 5 hours to flow through here.

Final Clean Product

Our outflow was rather rudimentary, but it did the job. We tore off a piece of t-shirt that directed the water into a small holding basin. From here, we used a small pump that took the clean water and moved it into another 55-gallon drum, that started off empty.

We started with exactly 55 gallons of dirty river water. Our goal was to end up with 40 gallons of clean water. The final product was 42 gallons of clean drinking water, which could have been increased if we eliminated some of the inefficiencies and water loss zones in the small system.

Here's the best part...

This system is completely portable, and could be transported and used virtually anywhere in the world. It would require some basic chemistry knowledge to get the chemical additions right, but if you wanted, you could treat water for a small village using this miniature treatment plant.

If you have absolutely any questions about more specifics on the system and how we tested and calculated everything, please leave a comment below and I will answer them. Feel free to ask other general water treatment questions as well, I am here to answer them!

Quality post. Thanks for the short tutorial, it was very interesting.

Thanks! I love bringing everyone else into some hidden science that makes the world go 'round. Feel free to direct any questions my way.

So would this work for the water in Flint, Michigan or water in Pennsylvania that has been contaminated by fracking? I would imagine it would work with municipal tap water with high silt and mineral content? I stayed overnight in Cody, Wyoming and the water was unbelievable. It was practical white with silt and minerals.

If so that would be a fantastic DIY domestic solution for people that have terrible water problems. This could be a great business opportunity in many communities.

Yes and no. This model is similar to what most cities would use to treat water on a much larger scale. What happened in Flint is government officials got lazy and decided to take from a terrible, corrosive water source. Much of the older pipes in the area were lead pipes. Now, these pipes previously weren't a problem because calcium and mineral deposits protected the water from contacting the lead pipes. When the treatment plant switched to the corrosive water, literally 50 years of protective scale was washed away in months, and the lead began leeching to the water, thus poisoning people.

I haven't looked into the exact chemistry needed to treat Flint water, and it would require a little bit of testing. However, if a trained civil engineer in the area had the resources, he could likely design personal systems to treat the water. The problem is these systems aren't going to be cheap, and it requires someone with decent training to operate. So, yes, a similar system could be designed for flint, but it would require quite a bit of work. Just getting the system built and researched for this mini treatment plant took me and 2 other engineers 4 weeks of intensive work.

To conclude, I think given enough resources, someone could develop a really good system for those with bad water supplies. The chemistry would need to be altered, but it could work.

Thank you so much for your detailed reply. I suppose it would be difficult to do personal setups in Flint, due to a lack of financial resources and large scale expertise. I'm sure the feds and state officials are pouring tons of money into fixing the problem and I wonder if your solution would be something that could work if it were scaled up with experts on the ground.

Might be worth a shot to email this article to the local newspaper? At the very least I would imagine the citizens would be interested in clean water solutions in whatever shape or form they come.

Thanks for reading the article! I will look into getting in touch with a newspaper. I currently write for a website called Interesting Engineering where I gave a little more in depth look into water treatment, if you're interested :)

Very cool.

So what is the flow rate of the final clean drinking water you get with this system? How much bleach was used for the disinfection step? And how many grams of alum were needed?

In total, we added 10.4 mL of 6% bleach, which worked out to a final concentration of around 3.15 mg NaOCl in the final treated water, within standard in our area. For alum, we added 62 mL of 10g/L Alum solution ever hour. This worked out to a total of about 1.3 L ofl Alum solution needed. The final testing flow rate was about 14 L/hr or 4 mL/min. All of these values were calculated from initial bacteria testing on a petri dish as well as flocculation testing to see where the optimum flocculant dosage was.

This is awesome :o

The life of a civil engineer ;)

If you were to heat water with solar and collect condensation would that be able to by itself clean water? No lead no bacteria etc?

Yep, that works. It's just hard to do that in large volumes.

Excellent work it's really a helpful post. My congratulations¡¡¡

Thanks! Hopefully it gave you some knowledge :)

It's quite a simple and amazing water treatment plant. We can use it anywhere as It's portable. Pure water is essential for us to avoid harmful diseases. If you are running your own business then you must it water purifier plant. You can visit a site to get free รับติดตั้งโรงงานผลิตน้ำดื่ม. They are also providing you a free cost estimation plan before buying. You can visit their site to plan a physical visit.